Smoking House ZXL

DESCRIPTION

Cost efficient solution to producing your own smoked meats, sausage, jerky, poultry, wild game or seafood with old-fashioned goodness and aromatic natural smoke flavor.

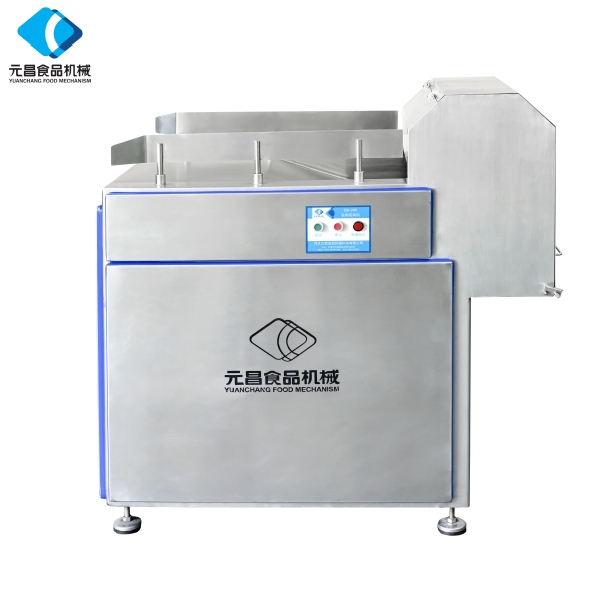

This machine uses large screen color man-machine interface display operation, Japan Omron programmable controller. Ensure stable operation of equipment. The improved double-layer high temperature system can be heated to 80 ° C in less than 15 minutes. The double-layer hollow glass door can clearly observe the changes of the product, and the process required for production can be set on the display screen. The unique steaming and fumigation structure can make the product color evenly.

Model

|

Specifications |

Model |

|||

|

ZXL-250 |

ZXL-500(DualChannel) |

ZXL-500 |

ZXL-1000 |

|

|

Capacity (kg/Time) |

250 |

500 |

500 |

1000 |

|

Power (KW) |

7.5/27 |

15/54 |

15/54 |

26/108 |

|

HP Steam Pressure (Mpa) |

0.4-0.6 |

0.4-0.6 |

0.4-0.6 |

0.4-0.6 |

|

LP Steam Pressure (Mpa) |

0.25-0.28 |

0.25-0.28 |

0.25-0.28 |

0.25-0.28 |

|

LP/HP Temperature (℃) |

110 |

110 |

110 |

110 |

|

Rated Voltage (V) |

380 (can change as need) |

380 |

380 |

380 |

|

Skip-car Dimensions (mm) |

1000*1000*1950 |

1000*1000*1950*2 |

1000*1000*1950*2 |

1000*1000*1950*4 |

|

Weight (Kg) |

1700 |

2600 |

2600 |

3600 |

|

Dimensions (mm) |

1680*2300*3000 |

2760*2300*3000 |

2760*2300*3000 |

5140*2300*3000 |

APPLICATION

Meat Smoker Oven Advantages:

Consistent quality.

High velocity air flow.

User friendly PLC interface screen thermostatic.

Time humidity system.

Meat SmokeHouse ZXL series is built with Swiss ABB electrics, super size man-machine interface and Japan Mitsubishi PLC. With the Japan SMC electric magnetism valves and pneumatics built-in, the Sausage smoking chamber can give a relatively stable and reliable operation. The improved high-temperature system of duel-layer flat rows can guarantee a fast temperature rising to 80℃ within only 15 minutes.

The dual hollow glass doors can make you clearly see the product processing. All real time parameters can be displayed on the screen for your designed presetting. Besides, its specialty and proprietary fumigating structure makes the products having a uniform color.

Smoke House Machine for Perfect Smoked Products

Achieving consistent and high-quality smoked products requires precise control of temperature, airflow, and smoke distribution. The Smoking House ZXL, part of Hebei Yuanchang Food Machinery Technology Co., Ltd.’s Ripening Process lineup, is a smoke house machine designed to meet these demanding requirements. Constructed entirely from SUS304 stainless steel, it ensures durability, corrosion resistance, and easy cleaning, which is essential for maintaining hygiene standards in industrial meat processing environments. With over 30 years of experience in meat processing and pet food machinery, Hebei Yuanchang has engineered the ZXL to combine modern technology with practical usability, making it suitable for both large-scale industrial facilities and smaller commercial operations.

The ZXL integrates a specially designed circulating fan system, maintaining an air cycle of 14 times per minute to guarantee uniform smoke penetration throughout the chamber. By combining low and high temperature air, smoke, and low-pressure steam, this industrial smokehouse allows precise control of product texture, flavor, and moisture content. Operators can adjust the processing parameters to achieve perfect smoked bacon, sausages, or other meat products, ensuring consistency across every batch. The chamber’s efficient airflow prevents cold spots and uneven smoking, which are common challenges in many commercial smokehouse operations, enhancing product uniformity and overall quality.

Safety and operational efficiency are further enhanced with features like a propane burner with thermostat for smokehouse, which provides reliable and controllable heat for smoke generation. The mini chief electric smoker module can be used for smaller batches or experimental runs, offering flexibility for varying production needs. Additionally, the smokehouse equipment’s stainless steel interior ensures rapid cleaning and prevents contamination, supporting continuous production while adhering to strict industrial hygiene standards. The combination of advanced airflow, heat, and smoke control allows operators to achieve optimal smoke flavor and texture consistently, improving overall productivity and product appeal.

The Smoking House ZXL represents a practical and high-performance solution for modern smokehouse operations. Its precise control over temperature, air circulation, and smoke density ensures uniform results, while its durable, easy-to-clean stainless steel construction guarantees long-term reliability. By integrating multiple features for safety, hygiene, and operational flexibility, the ZXL supports both small-scale and large industrial smokehouse workflows, reflecting Hebei Yuanchang’s commitment to high-quality, reliable machinery.

Smokehouse Equipment Optimizes Production Consistency

Maintaining uniform product quality in smoked meat requires precise control of airflow, temperature, and smoke exposure. The Smoking House ZXL, part of Hebei Yuanchang Food Machinery Technology Co., Ltd.’s Ripening Process series, excels as smokehouse equipment that ensures consistent results across every batch. Its combination of low and high temperature air, smoke, and low-pressure steam allows operators to achieve uniform texture, moisture, and flavor, addressing a common challenge in commercial meat processing. With its advanced circulation system, the chamber prevents cold spots and uneven smoking, enhancing product quality and production reliability.

The Smoking House also provides flexibility for different production scales. Its design integrates a commercial smokehouse equipment module that is ideal for larger batches, while the internal air circulation and smoke density can be finely adjusted to suit various meat types. As an industrial smokehouse, it is capable of handling high-volume production without compromising consistency, ensuring that each batch meets strict quality standards. This versatility allows facilities to meet diverse customer demands without investing in multiple machines. As a trusted choice among meat equipment suppliers, Hebei Yuanchang provides durable and reliable machinery that improves operational efficiency and batch-to-batch consistency.

Safety and hygiene remain central to the Smoking House’s design. SUS304 stainless steel construction ensures corrosion resistance and easy cleaning, while smooth interior surfaces reduce the risk of contamination during repeated use. Operators benefit from precise controls and stable smokehouse operation, which allows for reliable and repeatable processing. By using a smokehouse burner system, heat and smoke can be regulated efficiently, further enhancing consistency in flavor and texture while reducing material waste.

The Smoking House as smokehouse equipment enhances both production consistency and operational flexibility. It supports industrial meat processing workflows by providing uniform smoking, reliable temperature control, and easy maintenance. Facilities can maintain high-quality standards, reduce errors, and improve overall efficiency. With its combination of advanced technology and durability, the Smoking House reflects Hebei Yuanchang’s commitment to supplying high-performance solutions for modern smoked meat production.

Mini Chief Electric Smoker Enhances Safety and Maintenance

In modern smoked meat production, operator safety and ease of maintenance are as important as product quality. The Smoking House ZXL, part of Hebei Yuanchang Food Machinery Technology Co., Ltd.’s Ripening Process series, incorporates advanced mini chief electric smoker modules that allow precise control of smoke generation for small or experimental batches. This feature reduces the need for manual handling of hot materials, ensuring a safer working environment while maintaining consistent smoke flavor and texture. With over 30 years of experience, Hebei Yuanchang designs equipment that balances safety, hygiene, and efficiency in industrial operations.

The ZXL’s full SUS304 stainless steel construction and smooth interior surfaces make cleaning fast and efficient, reducing downtime between production cycles. Its smoke house equipment design integrates stable circulation fans and controlled heat sources, ensuring smoke is evenly distributed while operators can maintain a safe distance from hot surfaces and steam. These features not only prevent contamination but also simplify routine maintenance, supporting high hygiene standards critical in meat processing facilities. The combination of controlled smoke generation and easy cleaning reduces operational errors and improves overall workflow efficiency.

Durability and safety are further enhanced with the chamber’s reliable smokehouse equipment burner system, which allows precise regulation of heat and smoke. Operators can adjust temperature and smoke levels without exposing themselves to risks, while automated airflow circulation ensures uniform smoking throughout the chamber. This attention to safety and maintenance also improves the lifespan of the ZXL, making it a cost-effective choice for facilities aiming for both productivity and worker protection. By minimizing manual intervention and providing easy-to-clean components, the ZXL helps meat processors maintain consistent quality while keeping staff safe and production lines running smoothly.

The Smoking House ZXL combines mini chief electric smoker control, durable smoke house equipment, and efficient smokehouse equipment design to provide a safe, hygienic, and easy-to-maintain smokehouse solution. It exemplifies Hebei Yuanchang’s commitment to producing high-performance, reliable machinery for modern smoked meat operations, ensuring both product excellence and operational safety.