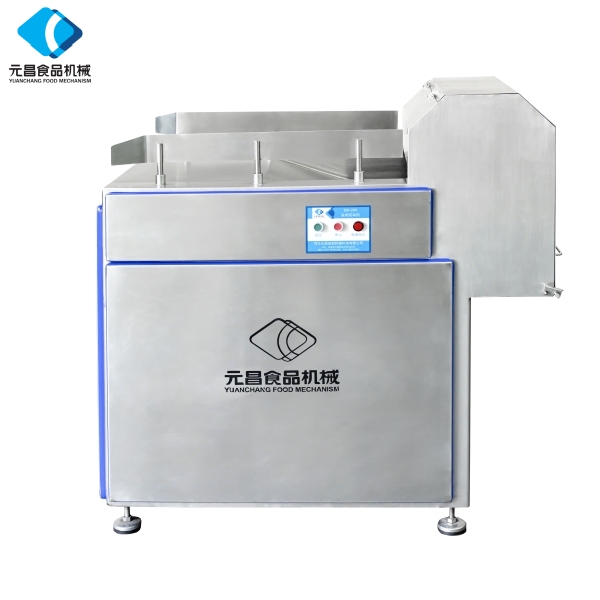

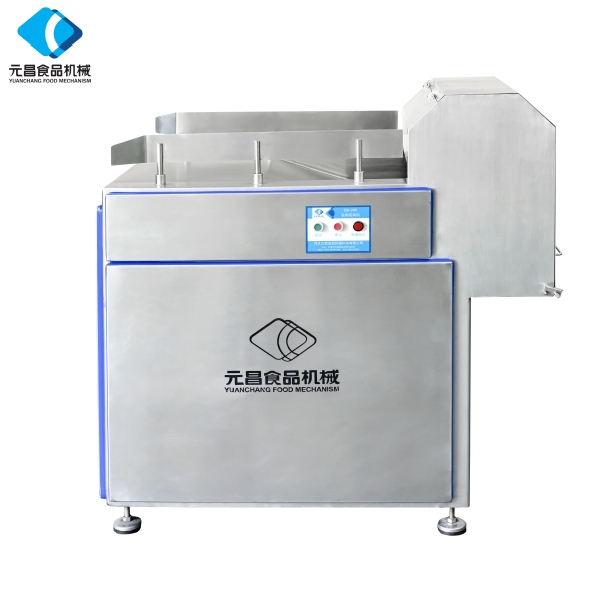

Frozen meat slicing (meat chunks)machine

Introduction

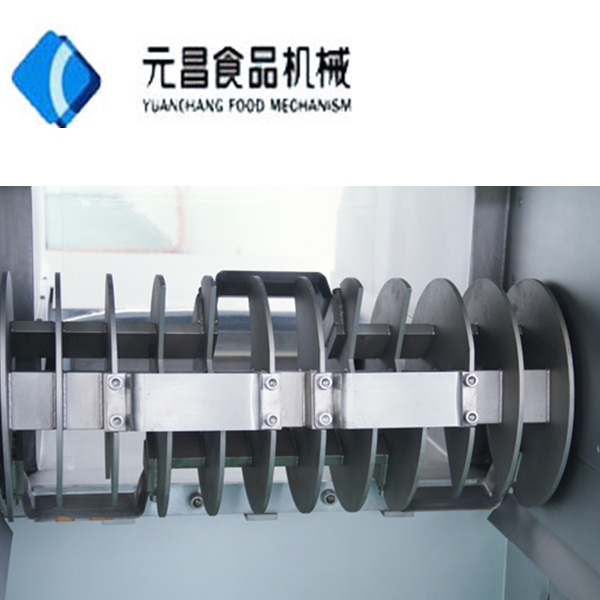

YC Mechanism Meat Cutter is specially developed to cut the frozen chicken and pork etc. at –18℃ and 0℃, which can greatly minimize the preparations for meat-borne food processing, a substantial saving on time and cost by placing the sliced meat into Grinders. Meanwhile the infection rate of bacteria can be largely reduced while the products shelf life is extended substantially, This Meat Cutter features robust construction, easy maintenance and high productivity and efficiency.

Model

FROZEN MEAT CUTTER

|

Model |

Capacity (T/h) |

Power (KW) |

Spindle speed(r/min) |

Voltage (V) |

Size (mm) |

|

QK-6T |

5-6 |

13.2 |

60 |

380 |

2050*900*1535 |

FROZEN MEAT FLAKER

|

Model |

Capacity (T/h) |

Power (KW) |

Spindle speed(r/min) |

Number of blades |

Voltage (V) |

Size (mm) |

|

QP-2000 |

3 |

7.5 |

60 |

6 |

380 |

2125*1060*1245 |

How Does a Frozen Meat Slicing Machine Support Food Safety?

Maintaining product safety while preparing large quantities of raw materials is a constant challenge in meat processing. A frozen meat slicing machine addresses this issue by working directly with frozen blocks, reducing the need for defrosting and thereby minimizing bacterial growth. By cutting meat at low temperatures, processors not only preserve natural proteins and color but also extend shelf life. This approach ensures that downstream processes, such as grinding, mixing, or forming, start with high-quality, stable ingredients.

The use of a frozen meat slicer is particularly valuable in preventing microbial contamination. Traditional thawing often leads to surface bacteria multiplying quickly, which compromises both safety and flavor. In contrast, slicing directly from frozen helps maintain hygiene standards while producing consistent slices or chunks. This feature is especially beneficial for industrial operations that require steady throughput and reliable results.

For larger facilities, a commercial frozen meat slicer provides added capacity and durability. Designed with stainless steel construction and robust cutting mechanisms, it can operate continuously under demanding conditions. Uniform slicing also improves efficiency, as evenly sized pieces move smoothly through subsequent stages of production. This efficiency reduces waste, saves labor, and ensures that every batch meets quality expectations.

The adaptability of a meat slicer for frozen meat further enhances its value. Whether preparing beef, pork, or poultry, the machine delivers precise cuts without damaging the meat’s natural structure. This consistency is vital not only for taste and texture but also for ensuring accurate portion control, which has direct implications for cost management.

Modern equipment, such as an industrial frozen meat slicer, reflects decades of engineering expertise. These machines combine solid structure, convenient maintenance, and automated features to meet the dual demands of safety and efficiency. By enabling processors to prepare meat in slices or chunks directly from frozen blocks, they provide a reliable foundation for safe, high-quality food production.

Why Invest in a Frozen Meat Slicer Commercial Unit?

For food processors and catering businesses, efficiency is not only about speed but also about cost control and product consistency. A frozen meat slicer commercial unit is specifically designed to meet these demands, allowing companies to process frozen blocks into uniform slices or chunks without prior thawing. By removing the defrosting stage, businesses save significant time and reduce the risks of bacterial contamination, ensuring safer products and longer shelf life.

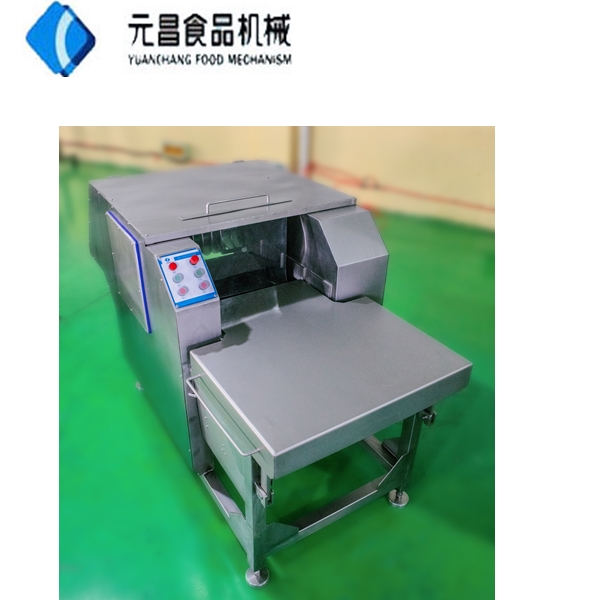

The reliability of an automatic frozen meat slicer enhances operational efficiency further. Equipped with programmable settings and automated feeding systems, these machines minimize manual intervention, which both increases throughput and improves workplace safety. Staff can focus on monitoring quality rather than repetitive labor, reducing fatigue while maintaining consistent results across shifts. This automation is particularly valuable for companies that need to process large volumes daily.

Energy efficiency and adaptability are also critical factors. A frozen meat slicer electric balances cutting strength with energy-saving features, making it suitable for continuous operation without excessive power consumption. Similarly, an electric frozen meat slicer provides precise control over cutting thickness and speed, allowing processors to customize output depending on recipe requirements. This flexibility means businesses can easily switch between preparing thin slices for hotpot restaurants, larger chunks for stews, or uniform cuts for further processing.

The broader category of a frozen food slicer extends the application of these machines beyond meat alone. Processors handling frozen vegetables, seafood, or mixed ingredients can benefit from the same accuracy and efficiency, making the slicer a versatile investment. By serving multiple functions within a single piece of equipment, companies reduce the need for additional machinery, lowering both capital investment and maintenance costs.

Manufacturers with decades of experience in food machinery have refined these systems to support high productivity while meeting stringent hygiene standards. Solid construction, easy maintenance, and automated safeguards ensure these slicers deliver reliable performance over time. For commercial operations seeking to increase efficiency and maintain consistent quality, frozen meat slicers remain an indispensable part of modern processing lines.

Can You Use a Meat Slicer for Frozen Beef?

When it comes to processing specific meat types, specialized equipment makes a significant difference in both quality and efficiency. A meat slicer frozen beef is designed to handle dense cuts directly from storage, producing uniform slices without requiring thawing. This ensures that the natural texture, flavor, and color of the beef are preserved, while also preventing bacterial growth that commonly occurs during defrosting. By maintaining low processing temperatures, the slicer supports both food safety and product shelf life.

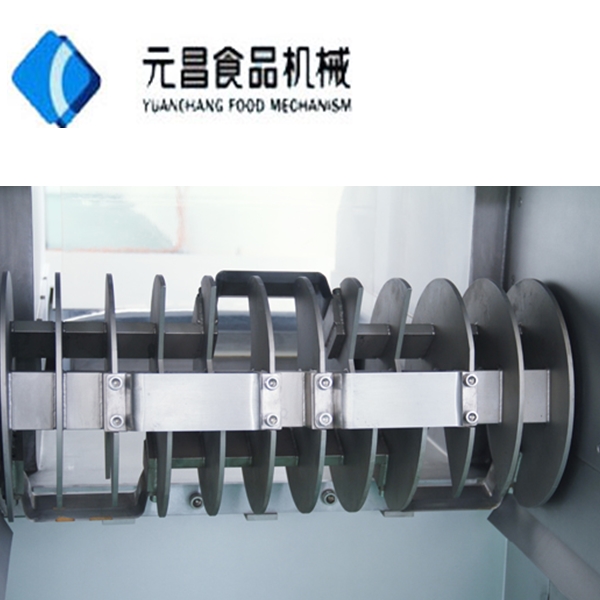

One of the common challenges operators face is slicing frozen meat with meat slicer while maintaining consistency. Professional machines address this by incorporating strong blades, adjustable thickness controls, and powerful motors that ensure smooth operation even with harder cuts. This technology reduces labor while producing reliable results, whether for further processing, portion control, or ready-to-cook applications.

The broader versatility of a frozen meat slicer also makes it suitable for other proteins such as poultry or pork. For catering businesses, butcher shops, or meal preparation companies, this adaptability is essential. Instead of relying on separate machines for each meat type, processors can achieve consistent results across different products using a single piece of equipment. This not only saves floor space but also simplifies staff training and maintenance.

In environments requiring larger throughput, an industrial frozen meat slicer ensures that even dense materials are cut efficiently. Built for durability and continuous operation, these machines are often paired with conveyors and automated feeding systems to support industrial-scale production. For smaller operators, compact models of frozen meat slicing machine provide the same hygienic and precise results but on a scale better suited for limited volumes.

With manufacturers refining these systems for decades, the modern slicer is more than just a cutting tool. It is a crucial part of pre-processing lines, ensuring processors can prepare frozen beef, poultry, or other proteins with maximum efficiency and consistent quality. By bridging versatility with precision, meat slicers continue to play an indispensable role across different processing environments.