Filling Flow Divider - Precision, Hygienic Multiline Dosing

Filling Flow Divider is a key solution in the Mechanical equipment manufacturing industry, specifically within Specialized equipment manufacturing and Manufacturing of specialized packaging equipment. This article explores how Hebei Yuanchang Food Mechanism & Technology Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Filling Flow Divider Overview

- Benefits & Use Cases of Filling Flow Divider in Manufacturing of specialized packaging equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Mechanical equipment manufacturing industry

- Conclusion on Filling Flow Divider from Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

Filling Flow Divider Overview

A Filling Flow Divider is a precision device that splits a continuous product stream into multiple equalized flows to feed downstream forming or packaging lanes. In specialized packaging equipment, it is indispensable for achieving consistent weight, shape, and presentation—whether you are depositing minced meat, plant-based mixes, sauces, or viscous pastes. By pairing with an automatic filling machine or broader automated filling machines, it balances throughput and accuracy across multiple lanes, enabling high OEE in modern lines.

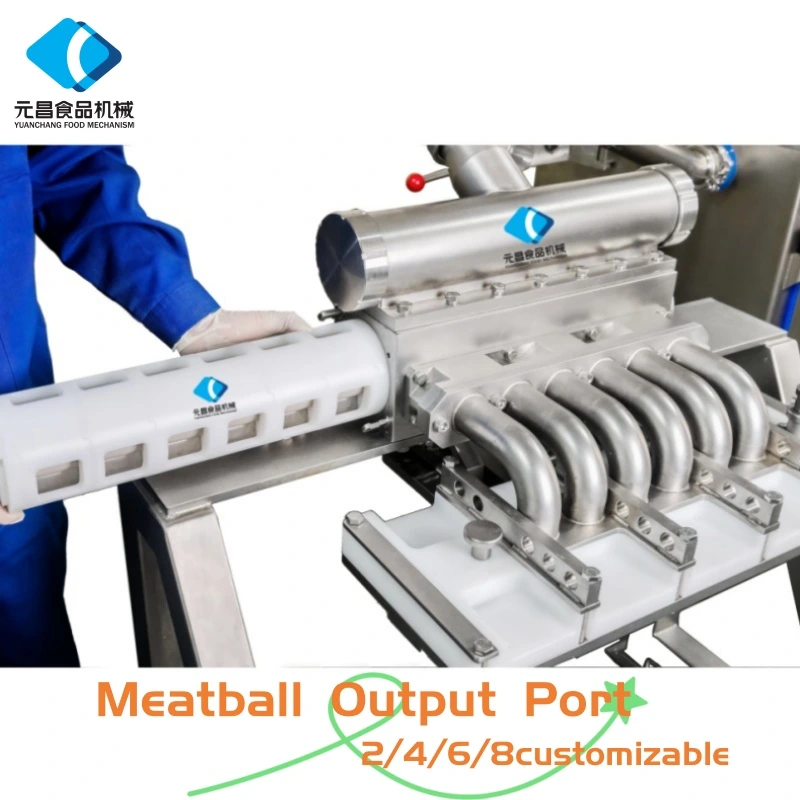

Hebei Yuanchang Food Mechanism & Technology Co., Ltd. engineers its Filling Flow Divider with hygienic design (304/316 stainless steel), servo or volumetric control for repeatable dosing, and PLC-based synchronization to thermoformers, tray sealers, or forming systems. Typical configurations allow multi-lane distribution, adaptable nozzles, and CIP-friendly pathways. In case applications such as burger patties, meatballs, dumplings, or croquettes, the system ensures each cavity or mold receives the same volume. As a reliable manufacturer serving the Mechanical equipment manufacturing industry, Yuanchang integrates the divider seamlessly with a filling machine, forming heads, and conveyors to deliver stable, scalable performance.

Benefits & Use Cases of Filling Flow Divider in Manufacturing of specialized packaging equipment

In packaging environments, a Filling Flow Divider solves the challenge of uniform multi-lane dosing. It feeds forming molds, tray cavities, pockets in thermoformers, or multi-nozzle depositors with equalized mass flow—critical for weight control and visual consistency. Applications span RTE protein packs, plant-based patties, dumplings and dim sum, pet food chubs, and ready-meal components. When integrated with an automatic filling machine, it supports higher throughput without sacrificing accuracy, minimizing rework and giveaway.

- Precision dosing: volumetric balance across lanes reduces product giveaway and protects margins in B2B manufacturing.

- Hygienic, tool-less changeover: sanitary design and quick swaps of nozzles/forming tools improve uptime.

- Smart integration: PLC/IPC controls synchronize with upstream mixers and downstream sealers, enabling fully automated filling machines and line-wide recipe control.

- Scalability: expand lanes or adapt to new product viscosities without replacing the core filling machine.

Backed by Hebei Yuanchang Food Mechanism & Technology Co., Ltd.’s expertise in food forming and packaging systems, customers receive a turnkey approach—flow division, forming, and automated filling machines configured to your substrates and throughput targets. The result is a competitive advantage in productivity and quality, whether your line is a compact auto filling machine cell or a multi-lane, high-speed packaging hall.

Cost, Maintenance & User Experience

Total cost of ownership is driven by uptime, yield, and sanitation efficiency. A robust Filling Flow Divider reduces giveaway through tight volumetric control and stabilizes lane-to-lane consistency—directly improving ROI. Hygienic design, rounded welds, and CIP-friendly circuits shorten washdown, lowering water, chemical, and labor costs. With modular wear parts and standard components, maintenance is predictable and spares are easy to stock across your filling machine fleet.

B2B users in specialized equipment manufacturing report smoother startups thanks to clear HMI guidance, recipe management, and self-diagnostics. Operators benefit from tool-less nozzle changes and quick lane balancing, minimizing downtime during product switchover. For multi-plant operators, Yuanchang provides training, documentation, and responsive aftersales support to keep automated filling machines running at target OEE. Over time, consistent portion control and reduced rework translate into measurable savings and a faster payback period.

Sustainability & Market Trends in Mechanical equipment manufacturing industry

Packaging lines face rising expectations around food safety, traceability, and resource efficiency. A modern Filling Flow Divider supports these goals by cutting product waste, enabling precise portioning, and supporting data capture for audit trails. Stainless steel construction and easy-to-clean geometries align with HACCP and good manufacturing practices, while energy-efficient drives help reduce the overall footprint of automated filling machines across the plant.

Market growth in ready-to-eat meals, premium pet food, and plant-based proteins demands flexible equipment that handles varied viscosities and particulates without compromising throughput. Hebei Yuanchang Food Mechanism & Technology Co., Ltd. invests in forward-looking design—compatibility with digital line control, predictive maintenance capabilities, and sustainable sanitation—to future-proof your automatic filling machine and flow dividing assets. This approach positions your operations to meet regulatory changes and consumer expectations while maintaining competitive productivity.

Conclusion on Filling Flow Divider from Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

In specialized packaging equipment, the Filling Flow Divider is central to accurate, high-speed, multi-lane production. By pairing with an automatic filling machine or broader automated filling machines, it safeguards yield, consistency, and compliance. Hebei Yuanchang Food Mechanism & Technology Co., Ltd. delivers dependable engineering, hygienic build quality, and end-to-end support that B2B decision makers trust. Ready to optimize your line? Contact us: email: ycmeatmech@gmail.com. Visit our website: https://www.ycmeatmech.com

-

Hopper Trolley: Heavy-Duty, Ergonomic, Easy DischargeNewsNov.18,2025

-

Frozen Meat Slicer for Ultra-Thin, Precise, Safe CutsNewsNov.17,2025

-

Smoke House Machine | Precise, Energy-Efficient, HACCP-ReadyNewsNov.17,2025

-

Smoke House Machine: Uniform, Energy-Efficient SmokingNewsNov.11,2025

-

Meat Filling Machine - Stainless, Precise, High OutputNewsNov.11,2025