- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

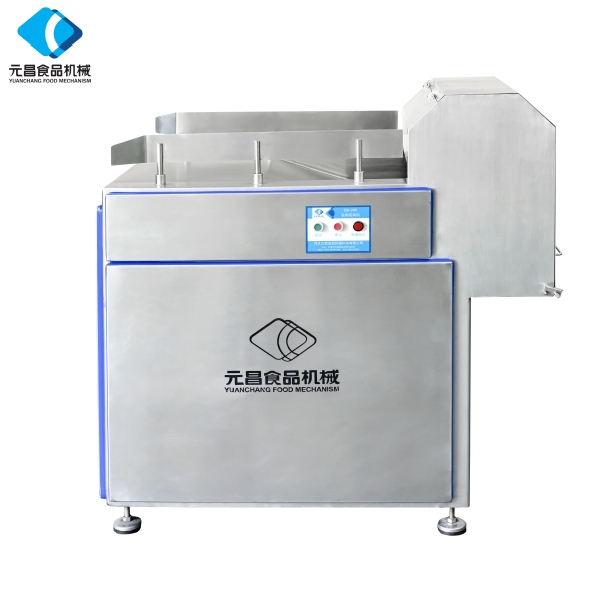

Frozen Meat Slicer for Ultra-Thin, Precise, Safe Cuts

Frozen Meat Slicer is a key solution in the Machinery and equipment industry, specifically within Food Machinery and Meat processing equipment. This article explores how Hebei Yuanchang Food Mechanism & Technology Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Frozen Meat Slicer Overview

- Benefits & Use Cases of Frozen Meat Slicer in Meat processing equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Machinery and equipment

- Conclusion on Frozen Meat Slicer from Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

Frozen Meat Slicer Overview

A Frozen Meat Slicer—also called a meat slicer for frozen meat or frozen food slicer—is purpose-built to cut hard-frozen blocks of beef, pork, poultry, fish, or mixed trimmings directly from storage temperatures. In industrial meat processing equipment lines, the machine prepares uniform slices, flakes, or chunks that feed downstream mixers, grinders, dicers, bowl cutters, and formers. By eliminating full thawing, processors protect protein functionality, reduce drip loss, and stabilize product quality from batch to batch.

Commercial specifications typically include stainless-steel construction (AISI 304), hygienic open-frame design, PLC touch control, variable slicing thickness, automatic infeed, and robust cutting assemblies engineered for frozen density. Depending on model, a commercial frozen meat slicer can handle standard frozen blocks and deliver high throughput with consistent thickness suitable for cooked, smoked, or IQF applications. Safety interlocks and ergonomic access simplify operation and cleaning in high-volume environments.

Hebei Yuanchang Food Mechanism & Technology Co., Ltd. manufactures dependable, production-proven systems that integrate seamlessly with existing conveyors and grinders. Backed by industry experience and service support, Yuanchang’s engineering team helps processors specify the right frozen meat slicer commercial solution—balancing capacity, cut profile, sanitation, and footprint—to meet plant-wide performance targets.

Benefits & Use Cases of Frozen Meat Slicer in Meat processing equipment

In modern plants, a Frozen Meat Slicer is positioned at the head of lines for sausages, deli meats, kebab/gyro, hotpot slices, jerky, pet food, and ready meals. Uniform frozen slicing improves grinder and mixer efficiency, while consistent piece size supports predictable brine uptake and thermal processing. For IQF and dicing lines, pre-slicing reduces stress on downstream knives, extending tool life and protecting final piece integrity.

Key advantages include uniformity, labor reduction, and minimized thawing time. Compared with manual or semi-manual methods, a commercial frozen meat slicer delivers repeatable target thickness across shifts, with less trim and fewer fines. Design features—such as PLC-driven feeds, robust cutting heads, and quick-change components—enable fast product changeovers and stable performance on diverse proteins. As a frozen meat slicer commercial supplier, Hebei Yuanchang focuses on hygienic design, safe access for sanitation, and integration with CIP-friendly practices to satisfy stringent QA standards.

Yuanchang’s application support helps customers match slice thickness and throughput to recipe requirements, whether feeding high-capacity grinders or precision bowl cutters. From single-machine upgrades to full line retrofits, the company’s engineering ensures the meat slicer for frozen meat aligns with production schedules, HACCP protocols, and operator workflow.

Cost, Maintenance & User Experience

Total cost of ownership for a Frozen Meat Slicer extends beyond purchase price. Processors evaluate throughput per shift, yield consistency, labor savings, and reduced pre-thaw holding. By slicing at frozen temperatures, plants can streamline cold storage logistics and help lower product losses associated with drip. These operational gains often accelerate ROI for a frozen food slicer when deployed in multi-shift environments or across diverse SKUs.

Maintenance considerations focus on hygienic access, tool-less disassembly, and durable wear components. Hebei Yuanchang Food Mechanism & Technology Co., Ltd. emphasizes cleanable, open-frame construction and straightforward sanitation protocols to shorten washdown windows. Operators benefit from intuitive controls and recipe memory, while maintenance teams appreciate clear access to service points and readily available spare parts. Feedback from Food Machinery users highlights stable uptime and more predictable downstream performance once uniform frozen slicing is implemented.

Sustainability & Market Trends in Machinery and equipment

Sustainability and regulatory compliance are shaping procurement decisions across Meat processing equipment. Cutting at frozen temperatures can support resource efficiency by shortening thaw cycles and helping to limit purge, which in turn supports yield management. Hygienic design aligned with global food safety frameworks (HACCP, CE-marked equipment, and good manufacturing practices) reduces contamination risk and promotes faster, water-efficient sanitation routines.

Market trends also favor automation-ready solutions with data visibility. Processors increasingly connect slicing, grinding, and mixing assets for line balancing and traceability. Hebei Yuanchang Food Mechanism & Technology Co., Ltd. develops forward-thinking equipment that integrates with upstream and downstream systems, enabling processors to adapt capacity, manage SKUs, and maintain quality under tighter labor markets. With a focus on energy-conscious drives, robust materials, and lifecycle support, Yuanchang positions each commercial frozen meat slicer as a durable, future-ready asset for evolving protein markets.

Conclusion on Frozen Meat Slicer from Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

For B2B decision makers, a Frozen Meat Slicer is a practical lever for throughput, yield consistency, and hygiene in Machinery and equipment—especially within Food Machinery and Meat processing equipment. By integrating reliable frozen slicing, plants stabilize upstream inputs and enhance downstream efficiency. Hebei Yuanchang Food Mechanism & Technology Co., Ltd. is a trusted partner, delivering robust designs, application expertise, and responsive service that align with modern compliance and sustainability goals.

- Contact us: email: ycmeatmech@gmail.com

- Visit our website: https://www.ycmeatmech.com

-

Filling Flow Divider - Precision, Hygienic Multiline DosingNewsNov.18,2025

-

Hopper Trolley: Heavy-Duty, Ergonomic, Easy DischargeNewsNov.18,2025

-

Smoke House Machine | Precise, Energy-Efficient, HACCP-ReadyNewsNov.17,2025

-

Smoke House Machine: Uniform, Energy-Efficient SmokingNewsNov.11,2025

-

Meat Filling Machine - Stainless, Precise, High OutputNewsNov.11,2025