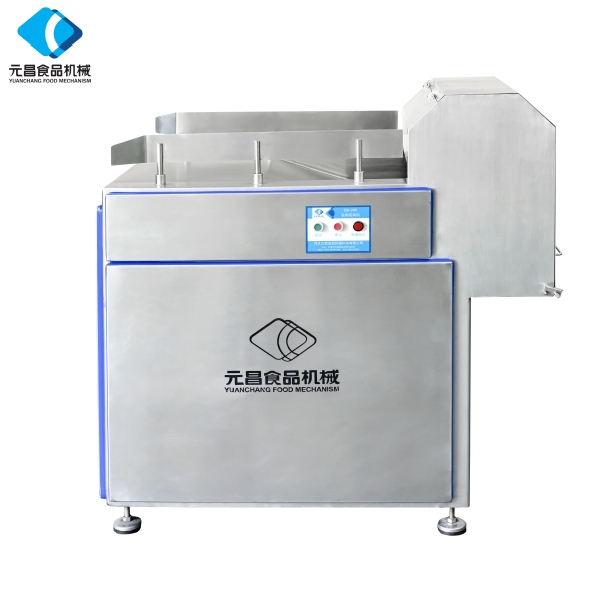

Additives Preparatory Maker RH-01

Introduction

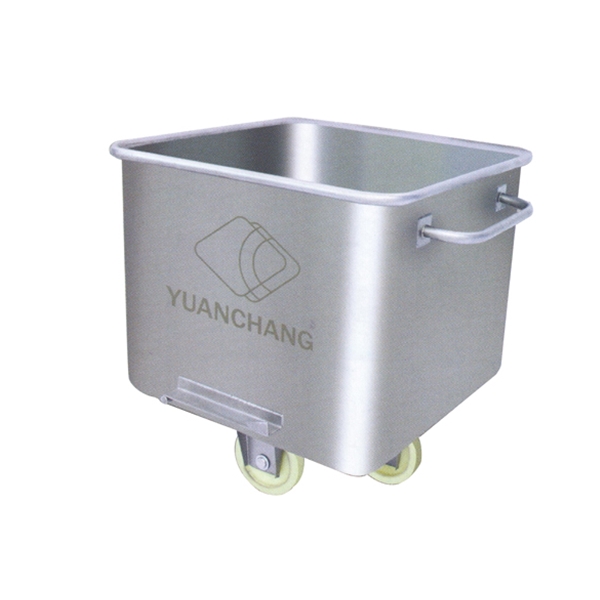

RH01 preparation device is an auxiliary equipment of saline injection machine. The water in the skip car and various auxiliary materials to be injected are fully stirred to achieve the purpose of emulsification. It is the ideal equipment for all kinds of saline injection machines.

Model

| Model | Power(kw) | Voltage(v) | Weight(kg) | Size(mm) |

| RH-01 | 1.5 | 380V | 56 | 930*830*1050 |

Application

This machine is reliable, durable, mobile, easy to operate, safe and so on. This machine has a unique design, which can grind various additives to a water emulsion, no particles, no clogging. It can be used with saline injection machine, chopping machine and rolling kneading machine produced by various manufacturers in the country.

Why RH-01 Is Essential for Saline Injection Efficiency

In meat processing, achieving uniform emulsification of water and additives is critical for both product quality and production efficiency. The Additives Preparatory Maker RH-01, part of Hebei Yuanchang Food Machinery Technology Co., Ltd.’s Food Industry Auxiliary Items range, is designed specifically to support saline injection machines. By thoroughly stirring water in the skip car along with various auxiliary materials, the RH-01 ensures complete emulsification, allowing subsequent injection processes to operate smoothly and consistently. With over three decades of experience in high-performance meat processing equipment, Hebei Yuanchang has engineered the RH-01 to meet the practical demands of modern food production lines.

The RH-01’s main advantage lies in its ability to achieve uniform mixing in every batch. Uneven distribution of additives or water can lead to inconsistent flavor, texture, or shelf-life, which impacts both consumer satisfaction and production efficiency. The RH-01 solves this problem through its precise agitation system, which maintains continuous movement and controlled speed. This ensures that all components, from water to complex additive mixtures, are fully emulsified before reaching the saline injection stage. Manufacturers can therefore reduce waste, avoid reprocessing, and maintain consistent quality across all products.

Another key feature of the RH-01 is its compatibility and flexibility. Designed as an auxiliary device, it integrates seamlessly with various types of saline injection machines without requiring major modifications to existing production setups. Its stainless-steel construction not only guarantees durability but also simplifies cleaning and maintenance, a crucial factor in hygiene-sensitive food processing environments. Safety mechanisms, including protective covers and emergency stops, further enhance its suitability for large-scale industrial use.

By facilitating complete emulsification, the RH-01 helps meat processors achieve more uniform injections, reduce production errors, and optimize operational efficiency. This aligns with Hebei Yuanchang’s commitment to providing reliable, high-performance machinery that supports every stage of meat and food processing. In essence, the RH-01 is more than just a preparatory device—it is an essential component in modern saline injection operations, ensuring consistent product quality and efficiency across the production line.

How RH-01 Simplifies Operation and Cleaning

In industrial meat processing, operational efficiency is closely linked to ease of use and maintenance. The Additives Preparatory Maker RH-01, part of Hebei Yuanchang Food Machinery Technology Co., Ltd.’s Food Industry Auxiliary Items lineup, addresses these challenges with thoughtful engineering designed for both operators and production managers. Serving as an auxiliary device for saline injection machines, the RH-01 thoroughly stirs water and auxiliary materials in the skip car, achieving complete emulsification. Beyond its technical mixing capabilities, the RH-01 stands out for its user-friendly design, allowing workers to manage complex processes with minimal training and effort.

The RH-01 is built with practicality in mind. Quick-disassembly components enable operators to remove key parts in minutes for cleaning or inspection, reducing downtime and maintaining production flow. All contact surfaces are made of high-quality, food-grade stainless steel, which resists corrosion and prevents contamination. This makes the RH-01 especially suitable for meat processing environments, where hygiene standards are strict and regulatory compliance is essential. Moreover, the machine’s intuitive controls provide precise adjustment of stirring speed and duration, allowing operators to tailor emulsification to specific product requirements without guesswork.

Safety and workflow efficiency are also central to the RH-01’s design. Protective covers prevent accidental contact with moving parts, while emergency stop mechanisms ensure immediate shutdown in case of unexpected events. These features not only protect operators but also contribute to uninterrupted production by minimizing the risk of equipment-related incidents. The compact layout of the RH-01 further allows seamless integration into existing production lines, ensuring that cleaning routines and ingredient preparation processes do not interfere with overall operational efficiency.

By focusing on ease of operation and hygiene management, the RH-01 helps meat processors maintain consistent additive preparation while reducing labor costs and downtime. This design philosophy reflects Hebei Yuanchang’s longstanding commitment to developing high-performance, reliable machinery for meat and food production. In practical terms, the RH-01 is more than an emulsification device—it is a tool that simplifies daily operations, supports strict hygiene standards, and ensures smooth, efficient production across the entire saline injection process.

How RH-01 Enhances Injection Consistency

Uniform saline injection is a critical factor in ensuring high-quality meat products. The Additives Preparatory Maker RH-01, developed by Hebei Yuanchang Food Machinery Technology Co., Ltd., plays a vital role in achieving consistent injection results. As an auxiliary device for saline injection machines, the RH-01 thoroughly mixes water and various additives in the skip car, creating a fully emulsified solution. This uniform preparation directly impacts the efficiency and precision of subsequent injection processes, helping producers maintain consistent product texture, taste, and appearance across every batch.

The RH-01 contributes to consistency in several ways. First, its continuous and controlled stirring prevents separation of additives and water, ensuring a homogeneous mixture for injection. Inconsistent emulsification can lead to uneven seasoning, moisture distribution, and texture, affecting both the shelf-life and sensory qualities of meat products. Second, the RH-01’s precise timing and agitation speed controls allow operators to adapt emulsification parameters according to different product types, from standard cuts to complex meat formulations. This flexibility ensures that every batch meets the desired standard without excessive trial and error.

Beyond technical precision, the RH-01’s robust design supports long-term operational stability. Its stainless-steel construction and corrosion-resistant components withstand heavy industrial use while maintaining hygiene standards. The machine’s compact and modular layout facilitates easy integration with multiple types of saline injection systems, allowing manufacturers to scale production without compromising emulsification quality. Safety features, such as protective covers and emergency stops, further ensure that consistent production is maintained without interruption due to accidents or equipment issues.

By enhancing injection consistency, the RH-01 not only improves product quality but also optimizes overall production efficiency. Producers benefit from reduced waste, lower reprocessing rates, and more predictable results, aligning with modern industry demands for reliability and high standards. This reflects Hebei Yuanchang’s commitment to providing high-performance machinery that supports every stage of meat processing. In essence, the RH-01 ensures that saline injection operations are precise, repeatable, and capable of delivering consistently excellent meat products.