Hopper Trolley: Heavy-Duty, Ergonomic, Easy Discharge

Hopper Trolley is a key solution in the manufacturing industry, specifically within Special Equipment Manufacturing Industry and Manufacturing of material handling equipment. This article explores how Hebei Yuanchang Food Mechanism & Technology Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Hopper Trolley Overview

- Benefits & Use Cases of Hopper Trolley in Manufacturing of material handling equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Hopper Trolley from Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

Hopper Trolley Overview

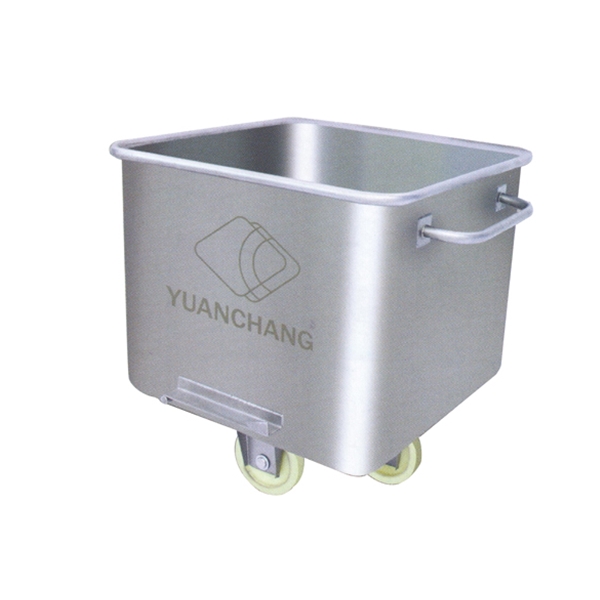

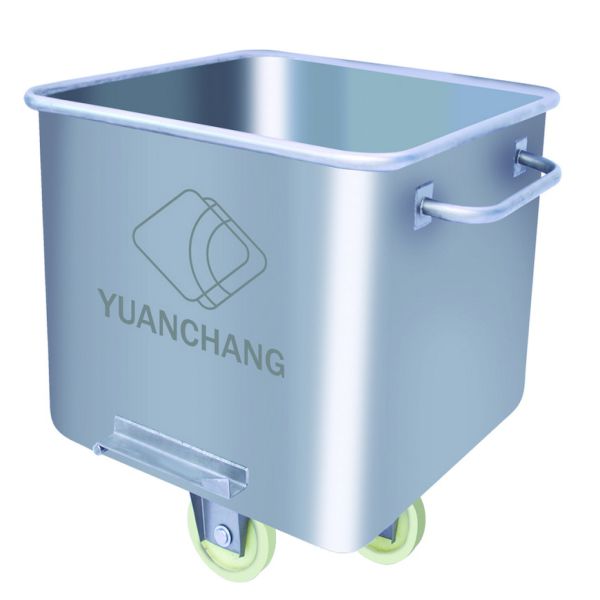

A Hopper Trolley—often referred to as a trolley hopper or 200L industrial buggy—is a mobile, deep-drawn stainless steel container engineered for safe, efficient transfer of bulk materials, trimmings, granules, or waste between processing stages. In the Special Equipment Manufacturing Industry and the broader Manufacturing of material handling equipment, this cart is a workhorse: it streamlines internal logistics, reduces manual handling risk, and interfaces seamlessly with lifters, dumpers, mixers, grinders, and conveyors. For hygiene-critical environments, its smooth, weld-finished interior minimizes residue traps and supports fast sanitation cycles.

Hebei Yuanchang Food Mechanism & Technology Co., Ltd. manufactures robust, food-grade Hopper Trolley solutions, such as the RC-200 configuration. Typical specifications include an approximate 200 L capacity, heavy-gauge stainless steel construction (with options for 304/316), reinforced rim, ergonomic push points, and high-load casters for stable movement. Radiused corners promote easy wash-down and safer handling. For manufacturers standardizing intralogistics, the consistent geometry integrates with automated tipping stations and batching systems, supporting repeatable, traceable operations. Whether moving meat trimmings, dough, pellets, spices, or castings, Yuanchang’s design philosophy centers on durability, compatibility, and operator safety.

Benefits & Use Cases of Hopper Trolley in Manufacturing of material handling equipment

In material handling equipment manufacturing, the Hopper Trolley is a versatile platform for batch transfer, work-in-process (WIP) staging, and controlled feeding of downstream equipment. Common applications include loading grinders and mixers, collecting off-cuts at trimming stations, buffering semi-finished products near ovens or chillers, and managing by-products for rendering or recycling. Beyond food, trolley hopper units are leveraged in pet food, nutraceuticals, industrial bakery, and light chemical settings, where cleanability, longevity, and dimensional consistency matter.

Key advantages delivered by Hebei Yuanchang Food Mechanism & Technology Co., Ltd. include seamless interiors for rapid wash-down, robust rims that resist deformation under frequent lifting, and caster assemblies selected for stability, low rolling resistance, and quiet operation. The standardized 200 L footprint enhances compatibility across existing fleets, minimizing changeover risk. For integrators and OEMs, this predictability simplifies the design of dumpers and lifts while reducing commissioning time. Yuanchang’s sector expertise ensures each Hopper Trolley meets the demands of continuous-duty environments—standing up to daily sanitation, temperature swings, and high-cycle usage without compromising operator ergonomics or line throughput.

Cost, Maintenance & User Experience

Total cost of ownership (TCO) for a Hopper Trolley hinges on life-cycle durability, sanitation time, and compatibility with existing handling systems. Yuanchang’s stainless construction resists corrosion and impact damage, protecting the investment over years of service. By standardizing on a 200 L trolley hopper, many plants reduce fleet variety and spare-parts complexity. Faster cleaning—enabled by smooth interior walls and accessible welds—shortens downtime and labor requirements, compounding ROI across multiple shifts. For B2B decision makers optimizing OEE, incremental gains in changeover speed and safer handling translate to tangible bottom-line benefits.

Maintenance is straightforward: daily rinse and sanitation, periodic inspection of casters and bearings, and timely replacement of wear items. Operators frequently note the stable ride, easy push force, and secure engagement with tipping equipment—enhancing user confidence and reducing fatigue. Feedback from Special Equipment Manufacturing Industry users highlights consistent batch transfer without rim deformation, simplified integration with automated dumpers, and improved hygiene scores after adopting seamless, easy-to-clean designs. The net effect is lower unplanned downtime, a safer shop floor, and predictable performance that supports stringent production schedules.

Sustainability & Market Trends in manufacturing

Material handling is evolving with stronger ESG expectations, stricter hygiene and safety frameworks, and elevated automation goals. Buyers increasingly prioritize long-life equipment that reduces waste, supports closed-loop cleaning practices, and minimizes chemical and water consumption. Stainless steel trolleys align with these goals thanks to their durability, recyclability, and ability to withstand repeated sanitation without coating loss. Standardized 200 L geometry also supports modular plant layouts, optimizing movement and reducing energy spent on rework or inefficiencies in flow.

Hebei Yuanchang Food Mechanism & Technology Co., Ltd. embraces these trends with Hopper Trolley designs that balance strength, hygiene, and lifecycle efficiency. The company emphasizes easy-to-service components, repairability, and parts availability to extend useful life and reduce waste. For manufacturers scaling automation, Yuanchang’s consistent dimensional tolerances support precise engagement with lifts and dumpers, enabling safer, cleaner, and more energy-efficient processes. The result is a forward-thinking, eco-conscious approach that helps plants meet evolving regulatory expectations while building resilient, future-ready intralogistics.

Conclusion on Hopper Trolley from Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

For manufacturers seeking reliability, hygiene, and seamless integration, the Hopper Trolley is a proven choice. It strengthens internal logistics, protects operators, and accelerates throughput across the Special Equipment Manufacturing Industry and the Manufacturing of material handling equipment. Hebei Yuanchang Food Mechanism & Technology Co., Ltd. stands out for robust construction, standardized geometry, and user-centered details that drive measurable operational gains. Ready to upgrade your fleet or specify for a new line? Contact us: email: ycmeatmech@gmail.com — Visit our website: https://www.ycmeatmech.com

-

Filling Flow Divider - Precision, Hygienic Multiline DosingNewsNov.18,2025

-

Frozen Meat Slicer for Ultra-Thin, Precise, Safe CutsNewsNov.17,2025

-

Smoke House Machine | Precise, Energy-Efficient, HACCP-ReadyNewsNov.17,2025

-

Smoke House Machine: Uniform, Energy-Efficient SmokingNewsNov.11,2025

-

Meat Filling Machine - Stainless, Precise, High OutputNewsNov.11,2025