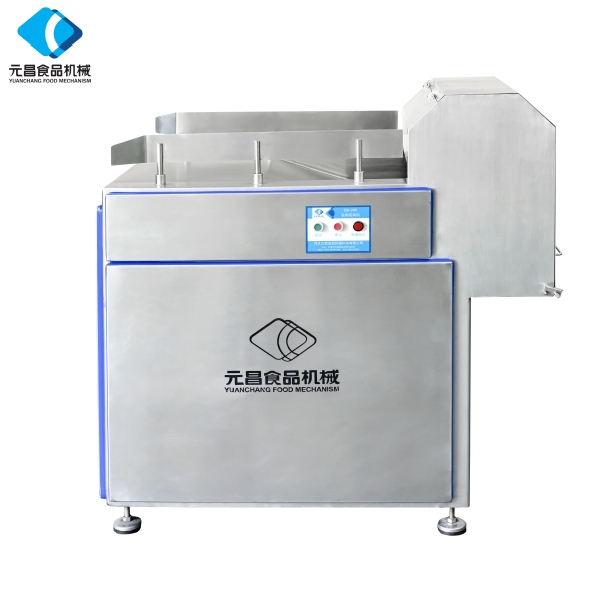

Meat Vacuum Mixer

DESCRIPTION

YC Machanism meat Vacuum Mixer with two shafts for mixing, with its specialty switching between clockwise and counter-clockwise rotation, the meat mixing speed and effect produced can be greatly improved. The vacuum level is adjustable to your option, making a more evenly-distributed raw material for better product quality. The air trapped in the materials during its front-end production processes can be sucked out, and an oxygen-free sterilize can be made to the materials, producing a superior looking of the meat under processing, and consequently the shelf lie of your products can be extended. Its made by stainless steel greatly facilitates your cleaning operation. The specialty pneumatics built-in can automatically open and close the cover and the discharger cover.

Customizable flip type for models up to and including 1200

Model

|

Model |

Capacity (Kg/time) |

Volume (L) |

Power (KW) |

Mixing speed (r/min) |

Vacuum level (Mpa) |

Voltage (V) |

Size (mm ) |

|

ZJB-150 |

120 |

150 |

3 |

0-50 Variable Frequency Drive |

0~ -0.085

|

380

|

1400*1100*1405 |

|

ZJB-300 |

220 |

300 |

6 |

1425*1240*1470 |

|||

|

ZJB-600 |

450 |

600 |

7 |

1610*1460*1610 |

|||

|

ZJB-1200 |

900 |

1200 |

12 |

2067*1780*1820 |

|||

|

ZJB-2000 |

1200 |

2000 |

24 |

2210*2080*2140 |

|||

|

ZJB-3000 |

2200 |

3000 |

32 |

3040*2080*2140 |

|||

|

Customizable flip type for models up to and including 1200 |

|||||||

APPLICATION