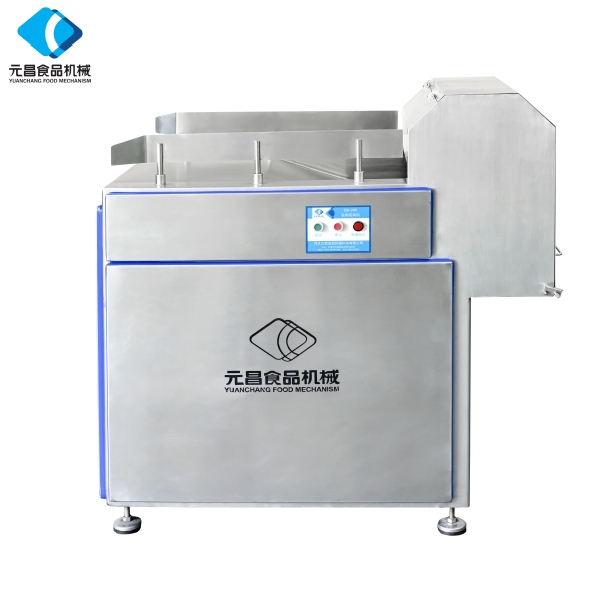

ELEVATOR T-200

Introduction

This machine lifts the material to a certain height and then pours it into the hopper system of the equipment to complete the feeding work. All stainless steel manufacturing, easy to clean, chain drive, smooth running, easy to operate. SUS304 stainless steel construction.

Model

| Model | Power(kw) | Lifting weight(kg) | Lifting speed(m/min) | Lifting height(m) | Size(mm) |

| T-200 | 1.5 | 200 | 7 | 1.9 | 1200*1100*3000 |

Application

This machine lifts the material to a certain height and then pours it into the hopper system of the equipment to complete the feeding work. All stainless steel manufacturing, easy to clean, chain drive, smooth running, easy to operate. SUS304 stainless steel construction.

How a Tilting Device Enhances Material Feeding

Efficient material handling is crucial in modern meat and food processing. The ELEVATOR T-200, part of Hebei Yuanchang Food Machinery Technology Co., Ltd.’s Food Industry Auxiliary Items lineup, is engineered to lift materials to a predetermined height and transfer them into the hopper system of production equipment. This automation reduces manual labor, maintains consistent material flow, and ensures smooth operation throughout the production line. With over 30 years of experience in high-performance meat and pet food machinery, Hebei Yuanchang combines durability, hygiene, and practicality in the design of the T-200, ensuring that it meets the demanding needs of industrial food production.

A standout feature of the T-200 is its integration with tilting device technology. This feature allows materials to be poured precisely into hoppers or other processing equipment, minimizing spillage and improving overall feeding accuracy. Consistent and controlled material flow is especially important when working with delicate or irregularly shaped products, where uneven feeding can affect texture, seasoning, and overall product quality. Meanwhile, the tilting machine mechanism ensures smooth and controlled movement during both lifting and pouring, which reduces the risk of sudden spills and operator fatigue. By combining these features, the T-200 provides a reliable and repeatable process that enhances production efficiency across different batch sizes.

The T-200 is constructed entirely from SUS304 stainless steel, which guarantees long-term durability, resistance to corrosion, and compliance with stringent hygiene standards. All surfaces in contact with food materials are easy to clean, reducing contamination risks and supporting safe, high-quality production. Its chain-driven lifting system operates quietly and efficiently, and the machine’s compact design allows it to be integrated seamlessly into existing production lines without major modifications. Operators can adjust the lifting height and pouring angle to match the requirements of specific products, further increasing operational flexibility and reducing downtime caused by manual adjustments.

By automating the lifting process and incorporating a precise tilting device and tilting machine, the ELEVATOR T-200 helps manufacturers achieve consistent material feeding, minimize labor requirements, and reduce waste. It is particularly effective in facilities where efficiency, hygiene, and repeatable quality are critical. This aligns with Hebei Yuanchang’s commitment to providing high-performance machinery that supports every stage of meat and food processing operations, ensuring reliable results in demanding industrial environments.

Tilting Machine Design Ensures Safety and Hygiene

Maintaining high standards of hygiene and operational safety is essential in meat and food processing. The ELEVATOR T-200, part of Hebei Yuanchang Food Machinery Technology Co., Ltd.’s Food Industry Auxiliary Items lineup, incorporates advanced tilting machine design features that address both concerns. By automating the lifting and pouring process, the T-200 reduces manual handling of materials, which minimizes the risk of contamination and ensures that food products maintain consistent quality. With over three decades of experience in high-performance meat and pet food machinery, Hebei Yuanchang has carefully engineered the T-200 to provide operators with a safe and hygienic work environment.

One of the key benefits of the T-200 is its full SUS304 stainless steel construction. All surfaces in contact with materials are corrosion-resistant and easy to clean, making routine sanitation quick and efficient. This is particularly important in facilities that process large volumes of meat or additives, where maintaining hygiene directly impacts product safety and shelf-life. The tilting device functionality allows precise pouring into hoppers or other equipment, preventing spills that could contaminate the production floor and ensuring uniform material handling throughout the process.

In addition to hygiene, operator safety is prioritized in the T-200 design. The machine features protective covers, stable chain-driven lifting mechanisms, and emergency stop systems, all of which reduce the risk of accidents during operation. The smooth running of the tilting machine ensures controlled motion even when handling heavy or unevenly shaped materials, further minimizing potential hazards. Operators benefit from an intuitive control interface that allows easy adjustment of lifting speed and pouring angles, ensuring precise operation without overexertion.

By integrating automated lifting with a robust tilting device mechanism, the T-200 supports both efficient feeding and strict hygiene standards. Manufacturers can reduce labor costs, maintain consistent material flow, and enhance workplace safety simultaneously. This combination of performance, safety, and cleanliness reflects Hebei Yuanchang’s commitment to delivering reliable, high-performance machinery that meets the evolving demands of the modern meat and food processing industry. In practice, the T-200 is not just a material feeder; it is a critical tool for maintaining safe, sanitary, and efficient production environments.

Tilting Device Boosts Production Flexibility

In high-volume meat and food processing, maintaining efficiency while adapting to different production needs is critical. The ELEVATOR T-200, part of Hebei Yuanchang Food Machinery Technology Co., Ltd.’s Food Industry Auxiliary Items series, enhances production flexibility through its advanced tilting device functionality. By lifting materials to a designated height and accurately pouring them into hoppers or processing equipment, the T-200 ensures smooth and continuous feeding, reducing downtime and optimizing workflow. With over 30 years of expertise in high-performance meat and pet food machinery, Hebei Yuanchang has designed the T-200 to handle diverse materials efficiently, supporting both small-scale and industrial production lines.

The combination of the tilting machine mechanism and a chain-driven lifting system allows the T-200 to handle materials of varying sizes, shapes, and weights without compromising feeding consistency. Operators can adjust the tilting angle, lifting speed, and pouring position to match specific product requirements, providing unmatched operational flexibility. This adaptability is especially valuable in facilities that process multiple product lines or switch between different additive or meat formulations, as it eliminates the need for extensive manual adjustments or separate feeding equipment.

Constructed entirely from SUS304 stainless steel, the T-200 not only guarantees durability and corrosion resistance but also simplifies maintenance and cleaning. Quick-access components enable operators to perform routine inspections and sanitation efficiently, further minimizing production interruptions. The smooth operation of both the tilting device and tilting machine components reduces the risk of mechanical failure and ensures precise, repeatable feeding every cycle. This consistent performance directly translates into higher production efficiency, reduced labor requirements, and minimized material waste.

By integrating automation, precision tilting, and flexible operation, the ELEVATOR T-200 improves both efficiency and adaptability in modern meat and food processing facilities. Manufacturers benefit from reliable feeding, smoother workflow, and the ability to respond quickly to changing production demands. This design philosophy aligns with Hebei Yuanchang’s mission to provide high-performance, dependable machinery that enhances every stage of meat and food processing, making the T-200 a key contributor to optimized production and operational flexibility.