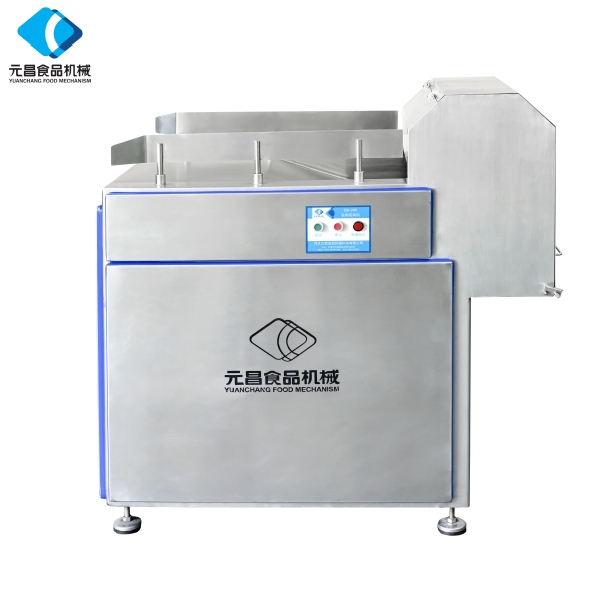

Meat Diced Machine

DESCRIPTION

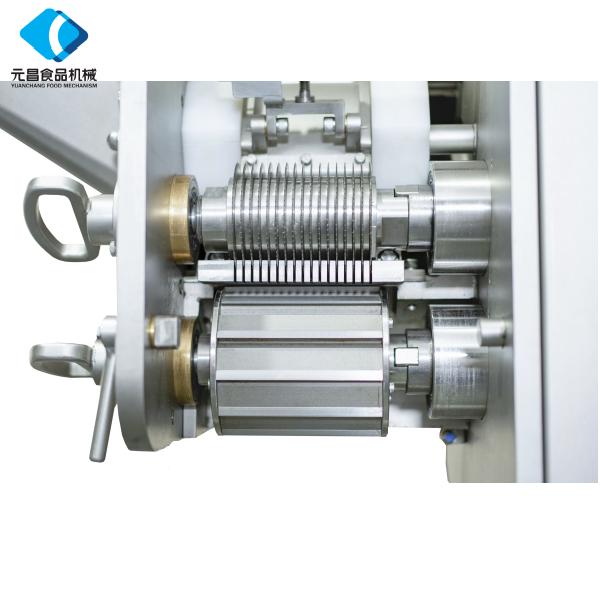

Main features: By adjusting the cutting knife set, the meat can meet different cutting requirements.

Centrifugal cutting reduces the squeezing of the product during the blade cutting process.

Model

| Model |

Power

|

Capacity |

Voltage

|

Weight

|

Dicing Size |

Size

|

| QD-350 | 8.5(kw) | 1-1(t/h) | 380(v) | 400(kg) | 5-15 (mm) | 1380×830×1260(mm) |

| QD-450 | 12 (kw) | 2-3(t/h) | 380(v) | 750(kg) | 5-20(mm) | 1850x1050x1500(mm) |

Why Choose a Meat Dicer Machine for Versatile Processing?

In meat processing, flexibility is often just as important as efficiency. A professional meat dicer machine is designed to provide both, offering precise cutting performance across a variety of raw materials. By adjusting cutting parameters, processors can achieve fine dicing, uniform slices, or cubes, making the equipment suitable for a wide range of recipes. Whether preparing ingredients for sausages, ready-to-eat meals, or pet food formulations, this type of machine helps ensure consistency and quality in every batch.

One of the key advantages of using a cube meat dicing machine lies in its ability to process different meat types with minimal preparation. Frozen meat, cooked meat, and even poultry with small bones can be handled effectively. This capability reduces the need for multiple machines on the production floor, saving space and lowering maintenance costs. By ensuring uniform cuts, the machine also improves downstream processing, whether mixing, tumbling, or forming, as each piece has the same texture and size.

For processors working with poultry, a dedicated chicken dicing machine ensures that cuts remain clean and uniform without tearing muscle fibers. This precision contributes to better cooking results and higher yield, as products maintain their natural texture and flavor. The ability to adapt between chicken, beef, or pork makes the dicer an essential part of diverse production lines, particularly for companies producing mixed meat products.

From a commercial perspective, a commercial meat dicer machine provides long-term value. Built with stainless steel components and equipped with safety mechanisms, it offers durability in continuous-use environments. The high efficiency of these machines means reduced labor, faster throughput, and better use of raw materials. For facilities seeking reliable pre-processing solutions, meat dicers bridge the gap between raw inputs and high-quality final products.

With decades of experience in food machinery, established manufacturers have refined these machines to meet evolving industry standards. Their designs balance innovation with practical operation, ensuring that processors can rely on equipment that is both robust and adaptable. By combining efficiency with versatility, the meat dicers available today remain indispensable tools for modern meat processing.

How Does a Frozen Meat Dicer Machine Improve Efficiency?

In large-scale food production, efficiency is critical. The ability to process high volumes quickly without compromising product quality directly impacts profitability. A frozen meat dicer machine addresses this challenge by handling solid blocks of frozen or semi-frozen meat with precision, eliminating the time-consuming defrosting step. This not only saves hours in production but also helps preserve natural proteins and color, maintaining the integrity of the final product.

When compared to manual or small-scale solutions, a commercial meat dicer machine offers significantly higher throughput. Built for continuous use, these machines are equipped with durable blades and automated feeding systems that reduce manual handling. By producing uniform cubes or slices at consistent speeds, they ensure downstream operations—such as mixing, tumbling, or forming—remain uninterrupted. For facilities working with multiple shifts, reliability and speed translate into measurable cost savings.

The versatility of a meat dice cutting machine further supports operational goals. Processors can adapt the settings to create fine cubes for sausages, larger pieces for stews, or uniform slices for ready-to-eat meals. This flexibility reduces the need for additional equipment, optimizing both space and investment. Combined with advanced safety features and easy-to-clean stainless steel construction, the machine enhances both hygiene and worker protection.

For buyers evaluating equipment options, a meat dicer machine for sale is more than just a single-purpose investment. It represents an opportunity to upgrade production lines with machinery that balances precision and efficiency. Manufacturers with decades of expertise in meat and pet food processing equipment have refined these designs to meet industrial standards, ensuring durability in demanding environments.

By providing consistent cuts, reducing processing time, and improving overall productivity, meat dicers continue to play an essential role in modern pre-processing lines. They are not only cutting tools but also efficiency drivers that help businesses remain competitive in the global food industry.

Is a Meat Dicer Machine for Home Use Practical?

While industrial processors often focus on large-scale production, there is also growing demand for smaller, user-friendly solutions. A meat dicer machine for home use caters to this need by providing efficient cutting capabilities in a compact design. Unlike manual methods, which are time-consuming and inconsistent, these machines deliver uniform cubes or slices of meat with minimal effort. For home chefs, small restaurants, or butcher shops, the ability to process fresh or frozen meat quickly is both practical and cost-effective.

One of the most appealing aspects of these machines is their adaptability. A compact cube meat dicing machine can be used for beef, pork, or poultry, enabling users to prepare diverse recipes such as stir-fries, soups, and ready-to-cook meals. The same technology applied in industrial facilities is scaled down for smaller operations, ensuring that quality and precision are not lost. For example, a chicken dicing machine provides clean cuts without tearing the meat, which is especially useful in preparing portion-controlled meals for families or small catering businesses.

Ease of use is another advantage. Most home-focused dicers come with straightforward controls and safety mechanisms, making them accessible to non-professional users. Cleaning is simplified by stainless steel construction and detachable parts, which helps maintain hygiene even in smaller kitchens. At the same time, their portability and smaller footprint make them ideal for settings where space is limited.

For small commercial operators, a frozen meat dicer machine offers additional flexibility. Being able to dice chilled or semi-frozen meat without thawing not only saves time but also preserves flavor and texture. This efficiency ensures that even small businesses can meet demand while maintaining consistent quality. Moreover, with more options available, a meat dicer machine for sale today can match different capacity requirements, from household models to entry-level commercial systems.

With the evolution of modern food machinery, meat dicers are no longer restricted to industrial-scale facilities. They now provide households and small businesses the ability to achieve professional-level results, bridging the gap between convenience and quality.