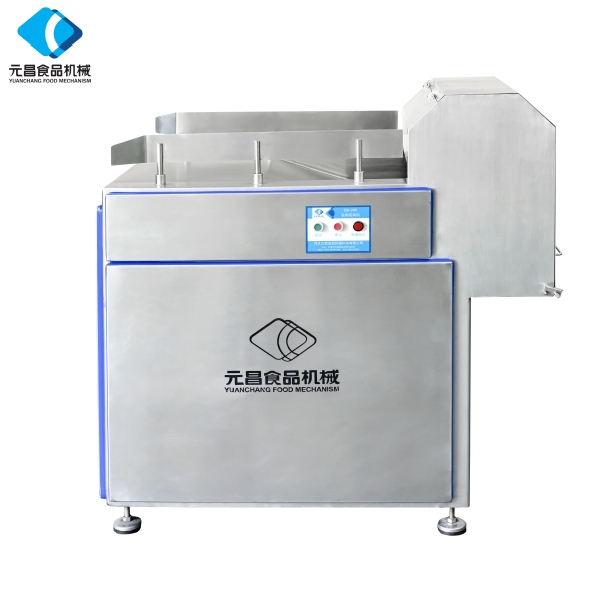

Frozen & Fresh Meat Grinder JR120,130,200,300

Introduction

YC Mechanism Grinder for frozen /fresh meat is specially designed to chop the meat at -18℃ and -24℃, can produce different sizes of minced meat and slices by changing the cutter. No obvious temperature rise can be made on the products, so the minimum bacteria level can be maintained for your products while the hemoglobin can be properly preserved, improving the shelf life of your products. It also boasts of easy operation and high productivity and efficiency.

Model

Model of hole :¢ 3、 ¢ 4、 ¢ 5、 ¢ 6、 ¢ 8、 ¢1 0、¢1 2、 ¢1 4、 ¢1 6、 ¢1 8、 ¢25

|

Model |

Capacity(T/h) |

Power (KW) |

Chopping cage diameter(mm) |

Chopping cage speed(r/m) |

Voltage (V) |

Weight (Kg) |

Size (mm) |

|

JR-120 |

1-1.5 |

7.5 |

120 |

250 |

380

|

260 |

1000 ×600×1200 |

|

JR-130 (Dual chopping cage) |

2-3 |

19 |

130 |

240/120 |

800 |

1400×1350×1750 |

|

|

JR-200 |

3-5 |

37 |

200 |

140 |

1050 |

1650×1100×1750 |

|

|

JR-300 |

4-7 |

55 |

300 |

50 |

2800 |

2050×1310×2450 |

Application

Frozen Meat Mincer Advantages:

Easy cleaning

Surface & Hopper stainless steel

Ejecting device for meat worm and cutting unit, manually operated

Hardly noticeable temperature rise with the final product

Drive shaft stainless steel, seated in special seals and ball bearings

Worm housing, meat worm and cutting unit stainless steel

How Does a Frozen Meat Grinder Ensure Food Safety?

Maintaining food safety while achieving efficiency is a critical requirement in meat processing. One solution widely adopted in the industry is the frozen meat grinder, which is specifically engineered to handle meat blocks at low temperatures. By working with semi-frozen raw materials, processors are able to reduce bacterial growth, preserve natural proteins, and extend product shelf life without compromising texture. Unlike traditional grinders that may increase the temperature of meat during processing, this design ensures the product remains safe and stable from start to finish.

The use of an industrial frozen meat grinder brings additional advantages to medium and large-scale production facilities. Its heavy-duty structure and precision cutting tools allow operators to manage continuous throughput with minimal downtime. The grinder is capable of reducing large frozen blocks into uniform pieces quickly, which makes downstream processes like mixing, tumbling, or forming far more consistent. This level of consistency not only improves efficiency but also directly affects the quality of sausages, patties, or pet food products that rely on uniform particle size.

When selecting raw materials, processors often rely on fresh meat for the grinder as well as frozen products depending on the recipe and seasonality. The ability to process both provides flexibility in production, enabling companies to adjust output based on market demand while maintaining the same hygienic standards. At -10 °C and above, equipment like the YC mechanism grinders developed by long-standing manufacturers ensures that the grinding process minimizes temperature rise, protecting color, flavor, and shelf life.

Among the more specialized machines is the frozen block grinder, designed to cut through compact blocks without prior defrosting. This not only saves time but also reduces the risk of contamination that can occur during thawing. For operations requiring finer textures, a frozen meat mincer becomes essential, enabling processors to grind frozen meat into smaller particles suitable for emulsified products. Each option has a specific role, but together they form a critical part of modern meat processing lines.

With decades of experience,specialize in meat and pet food machinery understand that safety, reliability, and performance are inseparable. Grinders built with stainless steel, easy-to-clean surfaces, and adaptable cutting systems make them indispensable tools for any processor seeking to balance food safety with high productivity.

Why Choose a Meat Grinder for High Efficiency Processing?

In industrial food production, achieving both speed and consistency is essential. A meat grinder designed for heavy workloads is the foundation of efficient processing lines, offering the ability to handle large volumes without compromising on quality. These machines are structured to deliver reliable performance shift after shift, minimizing downtime and ensuring consistent results. The grinder’s adaptability makes it suitable for a variety of recipes, from coarse mincing to fine textures required in sausages or pet food formulations.

One of the key advantages lies in the integration of precision engineering. An industrial frozen meat grinder is capable of breaking down semi-frozen raw materials quickly, which prevents the excessive temperature rise that often leads to bacterial growth. Similarly, when processors use fresh meat for the grinder, the outcome is uniform texture and improved shelf life thanks to controlled cutting mechanisms. These features directly influence product quality, making grinders a central element of both pre-processing and final product preparation.

Ease of operation is another critical factor in modern facilities. Grinders are equipped with user-friendly controls and automated feeding systems that reduce manual handling, thereby increasing worker safety and productivity. Cleaning procedures are also simplified through stainless steel construction, which supports hygiene standards and reduces turnaround time between production cycles. For companies running multiple shifts daily, the time saved translates directly into higher profitability.

Meat processing machinery manufacturers with decades of experience, especially those specializing in both meat and pet food equipment, bring added assurance to processors. Their grinders are built not only for performance but also for longevity, with robust designs that sustain continuous use. Whether dealing with large frozen blocks or chilled raw materials, equipment like the frozen block grinder or frozen meat mincer can be integrated seamlessly into production lines, ensuring processors have the flexibility needed for diverse markets.

In today’s competitive environment, investing in reliable pre-processing machinery is no longer optional—it is a requirement. A well-engineered grinder improves efficiency, preserves quality, and ensures that processors remain adaptable to evolving consumer demands.

How Can a Meat Grinder Improve Shelf Life?

In meat processing, one of the greatest challenges is balancing productivity with product integrity. The way raw materials are ground directly affects not only texture and flavor but also the safety and longevity of the final product. A professional meat grinder plays a vital role by operating at controlled temperatures that minimize microbial growth, ensuring that each batch meets hygiene standards while preserving freshness.

A critical factor in this process is the ability to grind frozen meat without defrosting. By reducing blocks at low temperatures, the grinder prevents the rapid bacterial multiplication that typically occurs when meat is thawed. This method retains natural proteins, stabilizes color, and extends storage time, making it particularly beneficial for large-scale facilities. Machines such as the frozen meat grinder or frozen meat mincer allow processors to work directly with chilled or semi-frozen materials, delivering uniform particle size without raising the temperature of the product.

Another aspect of shelf life management is the use of specialized equipment like the frozen block grinder, which eliminates unnecessary intermediate steps. Instead of waiting for meat to reach workable temperatures, operators can process directly from storage. This not only improves efficiency but also ensures that hemoglobin and moisture content are better preserved. Combined with precise cutting tools, the grinder maintains a consistent structure across batches, which is critical for applications ranging from sausages to pet food.

When incorporating fresh meat for the grinder, processors benefit from a different but equally important set of advantages. The grinder’s controlled action reduces smearing and retains the natural binding properties of the protein, which is essential for high-quality end products. For producers serving diverse markets, this dual capability—handling both frozen and fresh inputs—adds flexibility without compromising on safety.

Backed by more than three decades of innovation, manufacturers experienced in meat and pet food machinery design grinders that merge food science with engineering. Their stainless steel construction, user-focused design, and hygienic operation collectively help companies extend shelf life while meeting consumer expectations for taste and quality.