- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

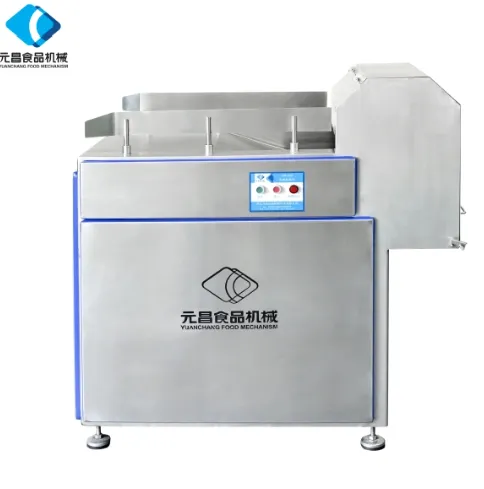

Introduction to Frozen Food Slicer

In the realm of food processing, the frozen food slicer has emerged as an indispensable tool, enabling the efficient and precise slicing of a wide variety of frozen ingredients. Whether in commercial kitchens, food processing plants, or home kitchens, this equipment plays a crucial role in streamlining food preparation processes. While related to frozen meat slicer and commercial frozen meat slicer, the frozen food slicer offers unique capabilities and applications. This article provides a comprehensive introduction to frozen food slicer, covering its features, types, benefits, and how it compares to other similar equipment, offering valuable insights for both professionals and enthusiasts in the food industry.

Key Features of Frozen Food Slicer

The frozen food slicer is equipped with several key features that set it apart. One of the most notable features is its ability to handle a diverse range of frozen foods. Unlike the more specialized frozen meat slicer, which is mainly designed for slicing frozen meats, the frozen food slicer can process everything from frozen meats and cheeses to fruits and vegetables. This versatility makes it a multi - purpose tool in any kitchen or food processing facility.

Another important feature is its adjustable slicing thickness. Most frozen food slicer models come with a user - friendly control mechanism that allows operators to set the desired slice thickness, ranging from paper - thin to thick slices. This feature provides flexibility in food preparation, catering to different recipe requirements. Additionally, safety is a top priority in the design of frozen food slicer. Many models are equipped with safety guards, non - slip bases, and emergency stop buttons to prevent accidents during operation, ensuring the well - being of users, much like the safety features incorporated in commercial frozen meat slicer used in professional settings.

Types of Frozen Food Slicer

There are different types of frozen food slicer available in the market, each designed to meet specific needs. Manual frozen food slicer is a popular choice for home kitchens and small - scale food operations. These slicers are operated by hand, offering simplicity and affordability. They are easy to use and require minimal maintenance, making them suitable for occasional use or for those who prefer a more hands - on approach to food preparation.

On the other hand, electric frozen food slicer is widely used in commercial kitchens and food processing plants. Powered by electricity, these slicers offer higher efficiency and faster slicing speeds compared to manual models. They often come with more advanced features, such as automatic feeding systems and programmable settings, which are essential for high - volume production. Similar to commercial frozen meat slicer, electric frozen food slicer is built to withstand heavy - duty use and can handle large quantities of frozen ingredients with ease.

Benefits of Using Frozen Food Slicer

Using a frozen food slicer brings numerous benefits to food preparation. Firstly, it significantly reduces the time and effort required for slicing frozen ingredients. Manually slicing frozen foods can be extremely challenging and time - consuming, but with a frozen food slicer, the process becomes quick and effortless. This increased efficiency is especially valuable in commercial kitchens and food processing plants, where large amounts of food need to be prepared in a short period, just as commercial frozen meat slicer boosts productivity in meat - focused operations.

Secondly, a frozen food slicer ensures consistent slice thickness, which is crucial for the quality and presentation of the final dish. Uniform slices cook more evenly, resulting in better - tasting food. Moreover, the ability to slice frozen foods directly eliminates the need for thawing, reducing the risk of bacterial growth and preserving the freshness and nutritional value of the ingredients. This makes the frozen food slicer a hygienic and practical choice for food preparation.

Comparison with Frozen Meat Slicer and Commercial Frozen Meat Slicer

While frozen food slicer shares some similarities with frozen meat slicer and commercial frozen meat slicer, there are distinct differences. Frozen meat slicer is specifically designed for slicing frozen meats and may not perform as well when it comes to other types of frozen foods. It often has features optimized for meat, such as specialized blade designs for cutting through different cuts of meat.

Commercial frozen meat slicer, on the other hand, is a heavy - duty machine used in professional settings for high - volume meat slicing. It is larger, more powerful, and built to handle continuous use. In contrast, frozen food slicer offers greater versatility, making it suitable for a wider range of applications. While commercial frozen meat slicer focuses on high - speed and high - capacity meat slicing, frozen food slicer balances functionality across various frozen ingredients, making it a more adaptable option for different food processing needs.

About Introduction to Frozen Food Slicer FAQS

What types of frozen foods can a frozen food slicer handle?

A frozen food slicer can handle a wide variety of frozen foods. It is suitable for slicing frozen meats, including beef, pork, and poultry. Additionally, it can process frozen cheeses, such as cheddar or mozzarella, into even slices for sandwiches or appetizers. Fruits like frozen strawberries, bananas, or mangoes can also be sliced for smoothies or desserts. Vegetables such as frozen carrots, cucumbers, or bell peppers are easily sliced for salads or stir - fries. This broad range of capabilities differentiates the frozen food slicer from more specialized equipment like the frozen meat slicer.

How does the safety of a frozen food slicer compare to that of a commercial frozen meat slicer?

Both frozen food slicer and commercial frozen meat slicer prioritize safety, but there are some differences due to their intended use. Frozen food slicer models, especially those for home use, come with basic yet effective safety features like safety guards to prevent fingers from getting near the blades and non - slip bases to keep the machine stable. Commercial frozen meat slicer, used in professional settings, has more advanced safety mechanisms. These include emergency stop buttons, interlocking systems that prevent operation when access panels are open, and more robust guarding to protect operators during high - volume, continuous use. However, both types of equipment are designed to minimize the risk of accidents during operation.

Can a frozen food slicer be used in a commercial kitchen?

Yes, a frozen food slicer can be used in a commercial kitchen. In fact, electric frozen food slicer models are commonly found in commercial settings due to their high efficiency and versatility. They can handle large quantities of various frozen ingredients, which is essential in a busy commercial kitchen. While commercial frozen meat slicer is dedicated to meat slicing, the frozen food slicer offers the advantage of processing different types of frozen foods, making it a valuable addition to any commercial kitchen's equipment lineup for diverse food preparation needs.

Is a manual frozen food slicer suitable for professional food processing?

A manual frozen food slicer is generally not the best choice for professional food processing. Professional operations typically require high - volume and rapid processing of frozen ingredients, which manual slicers cannot provide due to their slower slicing speeds and limited capacity. In contrast, electric frozen food slicer and commercial frozen meat slicer are designed for heavy - duty use, with features like automatic feeding systems and powerful motors to handle large quantities of food. Manual frozen food slicer is more suitable for home kitchens or small - scale, occasional use where the demand for slicing is lower.

How does the price of a frozen food slicer compare to that of a frozen meat slicer?

The price of a frozen food slicer can vary depending on its type, features, and brand. Generally, manual frozen food slicer models are more affordable and are often priced lower than specialized frozen meat slicer models, especially those with advanced meat - slicing features. Electric frozen food slicer models, especially those with high - end features suitable for commercial use, can be more expensive. Similarly, commercial frozen meat slicer, being a heavy - duty machine for professional use, also tends to have a higher price range. However, the price difference depends on specific models and their capabilities, and users should consider their needs and budget when choosing between the two types of equipment.

-

Filling Flow Divider - Precision, Hygienic Multiline DosingNewsNov.18,2025

-

Hopper Trolley: Heavy-Duty, Ergonomic, Easy DischargeNewsNov.18,2025

-

Frozen Meat Slicer for Ultra-Thin, Precise, Safe CutsNewsNov.17,2025

-

Smoke House Machine | Precise, Energy-Efficient, HACCP-ReadyNewsNov.17,2025

-

Smoke House Machine: Uniform, Energy-Efficient SmokingNewsNov.11,2025

-

Meat Filling Machine - Stainless, Precise, High OutputNewsNov.11,2025