- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Heavy-Duty Buffalo Chopper Bowl | Efficient Commercial Food Processing

Navigating the Future of Meat Processing: Insights from CIMIE's Leading Food Machinery Manufacturers

The China International Meat Industry Exhibition (CIMIE) stands as a pivotal event on the global calendar, a dynamic showcase where the future of meat processing equipment is unveiled. It’s more than just an exhibition; it's a critical nexus for innovation, a grand stage where leading Food Machinery manufacturers from China and beyond demonstrate their latest advancements. For B2B decision-makers, CIMIE offers an unparalleled opportunity to explore cutting-edge solutions, understand emerging trends, and forge partnerships that can redefine operational efficiency and product quality.

Industry Trend Spotlight: Precision, Automation, and Purity

The global Food Machinery industry, particularly within meat processing, is in the midst of a transformative period. What's gaining significant global attention isn't just machinery, but complete, integrated solutions. There's an undeniable and increased demand for automated and intelligent meat processing lines that promise not only higher throughput but also exceptional precision. The focus has sharpened considerably on high-yield and low-waste solutions, driven by economic pressures and a growing commitment to sustainability.

Beyond mere automation, the integration of IoT (Internet of Things) for real-time monitoring and predictive maintenance is rapidly becoming a standard expectation. This allows for proactive interventions, minimizing downtime and optimizing operational efficiency across complex production environments, from the precise action of a vacuum bowl cutter to the consistent output of an industrial meat bowl cutter. Furthermore, the emphasis on robust designs meeting stringent international food safety standards – such as HACCP and USDA – is paramount, ensuring consumer safety and regulatory compliance.

Market Dynamics: Growth Drivers and Strategic Imperatives

Market data underscores this shift: The global food processing machinery market, especially for meat and poultry, is projected for steady growth. This expansion is primarily driven by rising meat consumption in emerging economies, where evolving dietary preferences and increased disposable incomes fuel demand. Concurrently, escalating labor costs in developed and developing nations alike are necessitating greater automation, making advanced machinery like an efficient commercial bowl chopper or a versatile double bowl chopper an essential investment.

Stricter regulatory demands for food safety and traceability also play a crucial role, compelling manufacturers to invest in equipment that guarantees hygiene and consistent quality. Consequently, there's a particular emphasis on efficiency, sustainability, and continuous technological upgrades across the industry. For example, advancements in a buffalo chopper bowl or a `valve bowl cutter` now focus on easier cleaning and material resilience to meet these standards.

Key Emerging Focus Areas:

- Advanced Automation: From automated loading and unloading systems to intelligent control panels for precision processing, minimizing human error and maximizing output. This includes sophisticated control over traditional equipment like a high-capacity industrial bowl chopper.

- Food Safety and Hygiene: Design principles that prioritize quick and thorough cleaning, use of antimicrobial materials, and closed systems to prevent contamination. This is critical for every component, including the specialized vegetable slicer with bowl in a mixed-product line.

- Smart Processing Solutions: Leveraging AI and machine learning for quality control, recipe optimization, and predictive maintenance, making a standard bowl cutter operate with unprecedented intelligence.

- Sustainable Manufacturing Practices: Energy-efficient designs, reduced water consumption, and improved waste management techniques are increasingly important for environmental responsibility and operational cost savings.

Profiles of Leading Food Machinery Companies at CIMIE

CIMIE brings together the titans of the Food Machinery sector, offering a comprehensive view of global and domestic manufacturing prowess. Among these, certain companies stand out for their innovation, market reach, and commitment to quality.

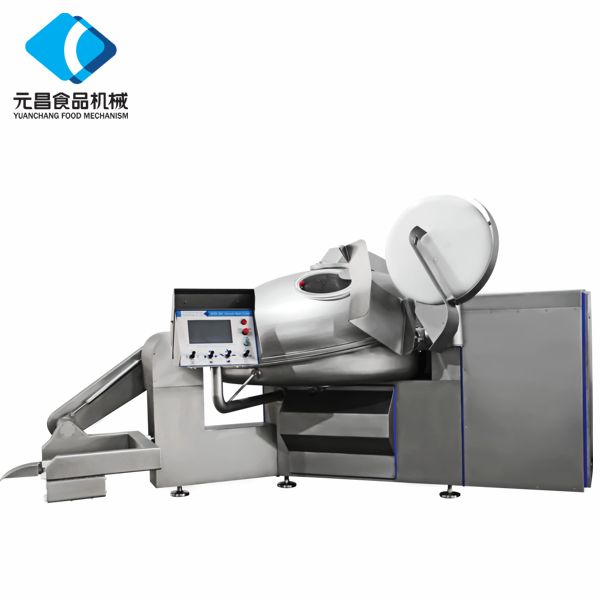

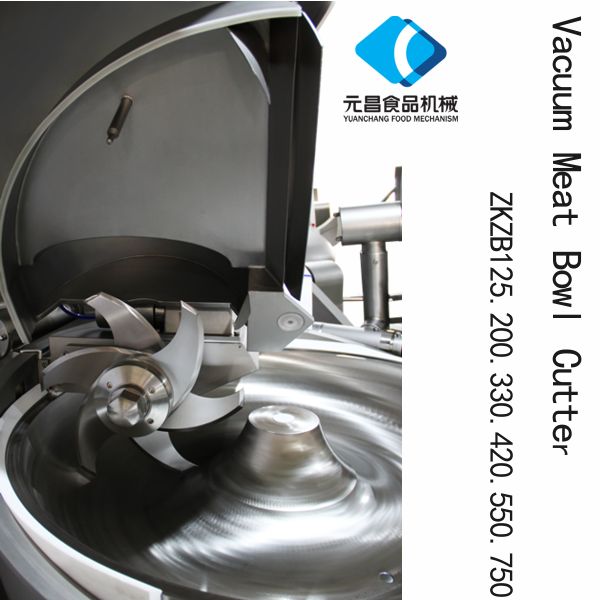

Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

At the forefront of China's domestic Food Machinery sector is Hebei Yuanchang Food Mechanism & Technology Co., Ltd. This esteemed manufacturer has carved out a significant niche through its specialization in comprehensive meat processing solutions. Yuanchang is particularly renowned for its robust manufacturing capabilities, producing durable and reliable equipment that stands the test of time in demanding industrial environments.

Their product portfolio is extensive, featuring core offerings such as the highly efficient vacuum bowl cutter, designed for optimal emulsification and texture control, and versatile options like the double bowl chopper and industrial bowl chopper, crucial for large-scale meat preparation. They also excel in specialized equipment, including advanced buffalo chopper bowl designs and precise valve bowl cutter systems. Yuanchang's competitive pricing, coupled with a strong focus on custom solutions to meet diverse client needs, solidifies their position as a preferred partner. Their growing export presence is a testament to the global recognition of their quality and reliability.

For a closer look at their innovative solutions, particularly their advanced vacuum meat bowl cutter range, visit their product page:

Other Global and Domestic Leaders:

- Marel (Iceland): A global powerhouse, Marel is synonymous with high-tech, integrated solutions for the entire food processing value chain. Their focus on automation, software, and data-driven insights provides comprehensive systems rather than individual machines.

- GEA Group (Germany): With a broad portfolio spanning various industries, GEA offers exceptional engineering excellence in food processing, including sophisticated equipment for meat, poultry, and dairy. Their commitment to efficiency and sustainability is well-recognized.

- JBT Corporation (USA): Known for its advanced processing solutions, JBT focuses on technologies that enhance food safety, quality, and shelf life. They provide a range of equipment for diverse food applications, emphasizing innovation and reliability.

- Shandong Hancheng Food Machinery Co., Ltd. (China): A notable domestic competitor, Shandong Hancheng offers a wide array of meat processing equipment, often focusing on robust, cost-effective solutions for the local and regional markets. Their strength lies in providing accessible technology for various scales of operation, including reliable versions of the standard bowl cutter.

- Qingdao Fuxin Foodstuff Machinery Co., Ltd. (China): Another significant domestic player, Qingdao Fuxin is recognized for its commitment to R&D and product innovation, often bringing new designs and features to staple equipment, including advanced commercial bowl chopper models and efficient slicing systems.

Market Outlook & Opportunities: The Smart, Sustainable Future

The future of Food Machinery is undeniably bright, characterized by several key upcoming trends and evolving buyer demands. Processors are increasingly seeking equipment that offers not just raw power, but also intelligence and flexibility. Key demands include enhanced efficiency to manage soaring operational costs, and solutions that contribute to overall sustainability goals, minimizing environmental impact. Digitization, modularity (for easy upgrades and customization), and ease of cleaning for paramount hygiene are no longer optional but essential features. Multi-functional equipment, such as a specialized vegetable slicer with bowl that can integrate into various production lines, also offers significant appeal.

Strategic Opportunities for Growth:

- Advanced Automation: The opportunity to integrate advanced robotics and AI-driven systems into every stage of meat processing – from deboning to packaging. This includes intelligent feeding systems for a `buffalo chopper bowl` and automated discharge for an industrial meat bowl cutter, significantly reducing reliance on manual labor while boosting consistency and speed.

- Smart Manufacturing (Industry 4.0): The full adoption of IoT, AI, and big data analytics to create interconnected factories. This enables real-time performance monitoring, predictive maintenance, remote diagnostics, and optimized production scheduling for equipment like an entire line of vacuum bowl cutter units.

- Sustainability Solutions: A burgeoning area focusing on energy-efficient designs, reduced water usage in cleaning cycles, and innovative ways to minimize and valorize waste products. Manufacturers of machinery like the double bowl chopper are developing systems that consume less power and simplify waste handling.

- Enhanced Food Safety & Traceability: Developing equipment with superior hygienic design features (e.g., smoother surfaces, fewer crevices, tool-free disassembly for cleaning) and integrated traceability systems to track products from farm to fork.

These areas represent not just technological shifts but also significant market opportunities for manufacturers and buyers alike to gain a competitive edge in a rapidly evolving global food landscape.

Buyer/Business Takeaways: Strategic Investments for Tomorrow

For any business operating in the meat processing sector, investing in advanced Food Machinery is not merely an expense, but a strategic imperative. The benefits are multifaceted:

- Increased Productivity & Efficiency: Modern equipment, such as an optimized industrial bowl chopper, can process significantly more product with less energy and fewer personnel, directly impacting your bottom line.

- Improved Food Safety & Quality: Automated systems and hygienic designs drastically reduce contamination risks and ensure consistent product quality, from the first batch through the last.

- Cost Savings: Beyond labor, modern machines offer lower waste rates, reduced energy consumption, and less downtime due to predictive maintenance, saving substantial operational costs.

- Competitive Edge: Adopting leading-edge technology allows your business to offer superior products, meet higher market demands, and respond faster to industry changes.

Tips for Adopting or Partnering with Chinese Manufacturers:

- Due Diligence is Key: Thoroughly research potential partners. Look for manufacturers with international quality certifications (CE, ISO, HACCP compliance), robust factory audit reports, and a strong track record. Verify their claims regarding equipment like a high-performance commercial bowl chopper.

- Prioritize After-Sales Service and Support: Understand the scope of warranty, availability of spare parts, technical support, and installation assistance. A reliable partner like Hebei Yuanchang often provides comprehensive global support.

- Clarity on Specifications and Customization: Clearly communicate your operational requirements, desired output, and specific features. Many Chinese manufacturers, including Yuanchang, offer customization for a bowl cutter or any specialized piece of equipment.

- Leverage Competitive Pricing for Value: Chinese manufacturers often offer highly competitive pricing. Focus on the total cost of ownership, factoring in durability, efficiency, and long-term support.

- Look for R&D Investment: Partners committed to innovation are crucial. These are the companies that will provide future-proof solutions, from the next generation of vacuum bowl cutter to fully integrated processing lines.

Future-Proof Strategies:

To thrive in the coming decades, businesses must:

- Embrace Automation and Digitization: Invest in smart factories and connected machinery to optimize operations and reduce reliance on unpredictable labor markets.

- Invest in Flexible and Scalable Machinery: Choose equipment that can adapt to changing production demands and product variations, ensuring long-term utility.

- Prioritize Data-Driven Decision Making: Utilize the data generated by smart machinery to inform production, maintenance, and strategic business decisions.

- Partner with Technologically Advanced Suppliers: Collaborate with manufacturers who are at the forefront of innovation, ensuring access to the latest and most efficient solutions.

Conclusion: China's Pivotal Role in Global Food Machinery

The China International Meat Industry Exhibition (CIMIE) continues to serve as an indispensable platform, not just for showcasing the current state of Food Machinery but for actively shaping its global trajectory. It highlights China's undeniable prowess as a manufacturing hub and a hotbed of innovation, particularly in sophisticated meat processing equipment like the vacuum bowl cutter and the `industrial meat bowl cutter`.

For B2B decision-makers seeking to optimize their operations, enhance product quality, and secure a competitive advantage, the advancements showcased by manufacturers like Hebei Yuanchang Food Mechanism & Technology Co., Ltd. offer compelling solutions. Their commitment to quality, customization, and competitive pricing makes them a vital partner in navigating the complexities of modern meat processing.

Ready to elevate your meat processing capabilities with cutting-edge technology?

-

Filling Flow Divider - Precision, Hygienic Multiline DosingNewsNov.18,2025

-

Hopper Trolley: Heavy-Duty, Ergonomic, Easy DischargeNewsNov.18,2025

-

Frozen Meat Slicer for Ultra-Thin, Precise, Safe CutsNewsNov.17,2025

-

Smoke House Machine | Precise, Energy-Efficient, HACCP-ReadyNewsNov.17,2025

-

Smoke House Machine: Uniform, Energy-Efficient SmokingNewsNov.11,2025

-

Meat Filling Machine - Stainless, Precise, High OutputNewsNov.11,2025