Precision Filling Flow Divider for Automated Filling Machines

Industry Trends in Precision Filling Technology

The global industrial automation market continues its robust growth, driven by increasing demands for efficiency, precision, and reduced operational costs across manufacturing sectors. In particular, the B2B landscape for filling flow divider systems is experiencing significant evolution. Companies are moving towards fully automated filling machines and integrated automated filling machines to enhance throughput and minimize product giveaway. Key trends include the integration of IoT for real-time monitoring, advanced analytics for predictive maintenance, and the development of highly adaptable systems capable of handling diverse product viscosities and container111 types. The impetus is clear: achieve consistent fill accuracy, optimize material usage, and ensure product integrity in an increasingly competitive market. This shift underscores the critical role of sophisticated components like the filling flow divider in achieving unparalleled operational excellence within automatic filling machine setups.

Furthermore, sustainability initiatives are influencing equipment design, favoring systems that reduce waste, consume less energy, and are built from durable, recyclable materials. The demand for hygienic designs, particularly in food & beverage, pharmaceutical, and cosmetic industries, is also pushing innovation in material science and cleaning-in-place (CIP) compatibility. Manufacturers are seeking solutions that not only meet stringent regulatory standards but also offer modularity and scalability to adapt to future production needs, making the core technology of the flow divider more vital than ever.

Understanding the Filling Flow Divider: Process Flow & Materials

A filling flow divider is a precision mechanical device designed to split a single incoming fluid stream into multiple, precisely equalized output streams. This capability is fundamental in multi-nozzle automated filling machines, where volumetric accuracy across all filling heads is paramount to prevent product overfill or underfill and ensure uniform product presentation. Its robust construction and meticulously engineered internal components are critical for reliable, long-term operation.

Process Flow of a Filling Flow Divider System:

1. Product Inflow: The product, whether liquid, semi-viscous, or pasty, is fed under pressure from a supply tank or pump into the central inlet of the flow divider.

2. Volumetric Division: Inside the divider, precision-machined gears or pistons rotate synchronously, capturing and displacing an exact volume of product with each rotation. The interlocking design ensures that each output channel receives an identical volume per cycle.

3. Multiple Output Streams: The precisely divided product is then discharged simultaneously through multiple outlets, each connected to a separate filling nozzle on the automatic filling machine.

4. Consistent Dispensing: This synchronized volumetric metering ensures that all container111s being filled at the same time receive an identical, highly accurate amount of product, regardless of variations in product viscosity or pressure fluctuations within the system.

5. Integration & Control: The flow divider operates as an integral part of an overall filling line, often controlled by a central PLC that manages fill volumes, speeds, and ensures synchronization with container111 indexing.

Product Materials & Manufacturing Processes:

The choice of materials is critical for the durability, hygiene, and chemical compatibility of a filling flow divider. Common materials include:

- Stainless Steel (304, 316L): Predominantly used for the main body, gears/pistons, and contact parts due to its excellent corrosion resistance, high strength, and hygienic properties. 316L is especially favored in food, pharmaceutical, and chemical industries for its enhanced resistance to chlorides and aggressive chemicals.

- Engineering Plastics (e.g., PEEK, PTFE): Used for seals, bushings, or specific internal components where chemical inertness, low friction, and wear resistance are required, especially with abrasive or highly viscous products.

- Ceramics: Occasionally used for extreme wear resistance in specific applications involving abrasive slurries.

Manufacturing processes emphasize precision and material integrity:

- Casting/Forging: Used for the main housing, providing a strong, unitary structure that withstands high pressures.

- CNC Machining: Critical components like gears, pistons, and internal chambers undergo extensive CNC machining to achieve micron-level tolerances, essential for precise volumetric displacement and minimal internal leakage.

- Surface Treatment: Polishing, electro-polishing, or passivation often applied to contact surfaces to enhance hygiene, corrosion resistance, and reduce product adhesion.

- Precision Assembly: Components are assembled in controlled environments to maintain cleanliness and functional integrity, followed by rigorous calibration.

Testing Standards & Service Life:

To ensure performance and reliability, filling flow divider units are manufactured and tested against stringent international standards:

- ISO 9001: Certifies the quality management system throughout design, manufacturing, and service.

- ANSI/ASME Standards: Govern dimensions, material specifications, and pressure ratings for pipeline components and fittings.

- CE Marking: Ensures compliance with European safety, health, and environmental protection requirements.

- FDA/3-A Sanitary Standards: For components used in food, beverage, and pharmaceutical industries, ensuring material compatibility and cleanability.

With proper selection, installation, and routine maintenance, a high-quality filling flow divider can offer a service life typically ranging from 5 to 10+ years, even under continuous heavy-duty industrial operation. Regular inspection of seals and rotating parts is recommended to maximize longevity.

Technical Specifications & Performance Parameters

The performance of a filling flow divider is defined by several critical technical parameters that directly impact filling accuracy, speed, and suitability for specific applications. Understanding these specifications is essential for B2B decision-makers and engineers in selecting the optimal unit for their automated filling machines.

Typical Product Specifications: Filling and Flow Divider Forming Machine

| Parameter | Specification | Notes / Impact |

|---|---|---|

| Model Series | YCMF-FD-Series | Modular design for various applications |

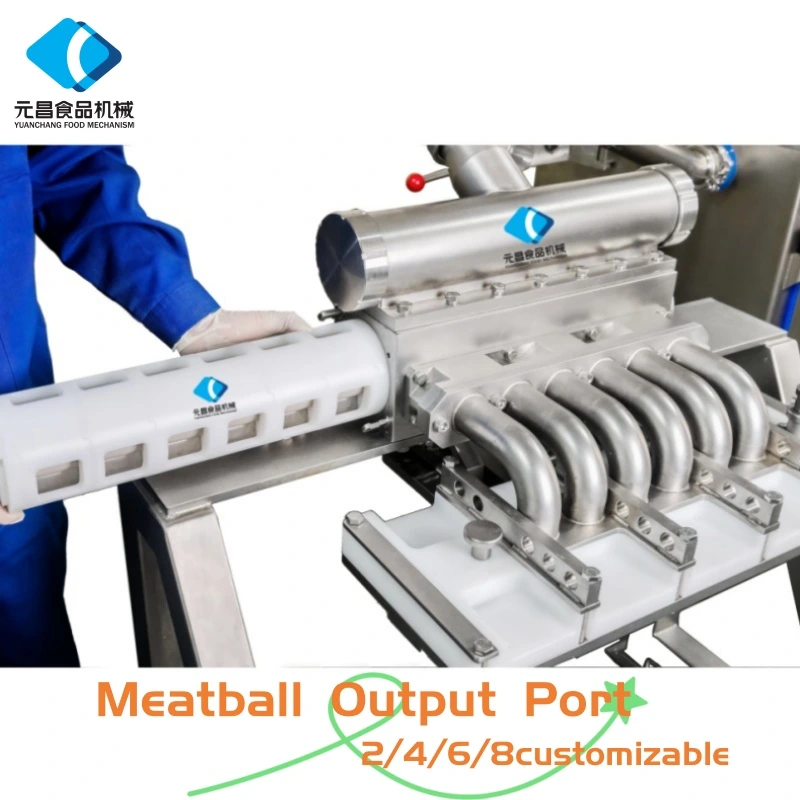

| Number of Outlets | 2, 4, 6, 8, 10, 12, 16 | Configurable based on filling machine capacity |

| Flow Rate Range per Outlet | 50 mL/min to 1500 mL/min | Dependent on model and product viscosity |

| Volumetric Accuracy | ±0.5% (typically better than ±0.2%) | Achievable with stable inlet pressure and uniform product |

| Max. Operating Pressure | 10 bar (145 psi) | Suitable for most industrial filling applications |

| Viscosity Range | 1 cP to 100,000 cP+ | Handles low-viscosity liquids to highly viscous pastes |

| Operating Temperature | -10°C to +80°C | Extended ranges available upon request |

| Wetted Materials | SS316L, PEEK, PTFE (FDA compliant) | Selected for chemical compatibility and hygiene |

| Connections | Tri-clamp, DIN, NPT, Flange | Standard industrial and hygienic fittings |

These specifications are crucial for ensuring compatibility with existing filling lines, meeting regulatory requirements, and achieving desired production targets. The high accuracy and broad viscosity range of our filling flow divider solutions position them as ideal components for demanding B2B applications, from pharmaceutical liquids to industrial lubricants.

Key Technical Advantages

Implementing a high-performance filling flow divider yields significant operational and economic advantages for automated filling machines:

- Unparalleled Volumetric Accuracy: Our flow dividers consistently achieve accuracies of ±0.5% or better across all outlets. This virtually eliminates product giveaway, significantly reducing material costs and improving profit margins, especially with high-value liquids.

- Enhanced Production Consistency: By ensuring uniform fill volumes at every nozzle, product quality is maintained across entire batches, leading to fewer rejections and greater customer satisfaction.

- Broad Viscosity Handling: Designed with robust internal mechanisms, these dividers can precisely handle a wide spectrum of product viscosities, from thin solvents to thick creams and pastes, without compromising accuracy.

- Corrosion Resistance & Hygiene: Manufactured from medical-grade SS316L and FDA-compliant polymers, our units offer exceptional resistance to corrosive chemicals and facilitate easy CIP/SIP (Clean-In-Place/Sterilization-In-Place) protocols, crucial for sensitive industries.

- Reduced Product Waste: Precise dosing minimizes overfilling, directly translating into tangible savings on raw materials and reduced environmental impact from product waste.

- Increased Throughput & Efficiency: By enabling simultaneous, accurate multi-nozzle filling, the overall production speed of the automatic filling machine is significantly boosted, optimizing labor and machine utilization.

- Long Service Life & Low Maintenance: Featuring precision-machined, hardened components and robust bearing systems, these dividers are built for continuous operation with minimal wear, leading to extended operational periods and reduced maintenance downtime. This also contributes to energy saving by ensuring consistent performance without frequent adjustments or replacements.

- Seamless Integration: Designed for straightforward integration into existing or new automated filling machine lines, with various connection options and compact footprints.

Application Scenarios & Target Industries

The versatility and precision of the filling flow divider make it an indispensable component across a multitude of industries requiring accurate liquid dispensing:

- Food & Beverage: Critical for bottling sauces, dairy products, juices, edible oils, and viscous food items. The hygienic design (SS316L, FDA-compliant seals) ensures product safety and easy cleaning, maintaining product integrity and shelf life.

- Pharmaceutical & Nutraceutical: Essential for accurate dosing of syrups, suspensions, liquid medications, and dietary supplements. Precision prevents costly errors and ensures compliance with strict regulatory requirements (e.g., cGMP).

- Cosmetics & Personal Care: Used in filling creams, lotions, shampoos, perfumes, and makeup. Consistency in fill volume is vital for brand image and product presentation.

- Petrochemical: Applied in dispensing lubricants, oils, chemical additives, and specialized fluids. The robust construction and material selection ensure corrosion resistance against aggressive chemicals, enhancing safety and equipment longevity.

- Chemical Industry: For precise filling of various industrial chemicals, detergents, and cleaning agents. Offers excellent chemical compatibility and prevents cross-contamination.

- Water Supply & Drainage: While not directly for consumer filling, flow dividers can be used in chemical dosing stations for water treatment, ensuring precise chemical addition for purification or pH adjustment, leading to energy saving by optimizing chemical usage and reducing reprocessing needs.

In each of these scenarios, the filling flow divider contributes to significant operational advantages. For instance, in petrochemical applications, its corrosion resistance ensures reliable performance even with aggressive media, preventing costly downtime and equipment failure. In the food sector, its precision and hygienic design translate directly into reduced product waste and enhanced food safety, contributing to overall energy saving by minimizing rejected batches and optimizing resource utilization.

Vendor Comparison: Key Differentiators

Choosing the right vendor for a filling flow divider is a critical decision that impacts long-term operational efficiency and total cost of ownership. While many suppliers offer flow dividing solutions, key differentiators in design, manufacturing quality, support, and customization capabilities set leading providers apart. A comparative analysis helps highlight these distinctions.

Flow Divider Vendor Comparison

| Feature/Criteria | Our Product (YCMF-FD-Series) | Competitor A (General Market) | Competitor B (Specialized Niche) |

|---|---|---|---|

| Volumetric Accuracy | ±0.2% (typical) | ±1.0% to ±0.5% | ±0.3% to ±0.1% (often higher cost) |

| Wetted Materials | SS316L, PEEK, PTFE (FDA/3-A compliant) | SS304, standard polymers | Exotic alloys, ceramics (for extreme cases) |

| Viscosity Range | 1 cP - 100,000 cP+ (broad) | Limited to moderate range (e.g., 5-50,000 cP) | Very specific high or low viscosity (narrow) |

| Manufacturing Certifications | ISO 9001, CE, 3-A equivalent | Basic quality checks | Specialized certifications (e.g., ATEX) |

| Customization Options | High (outlets, materials, connections) | Limited standard options | Moderate to high, but niche-focused |

| After-Sales Support | Comprehensive (tech support, spare parts, training) | Basic warranty, limited parts | Good, but potentially slower response due to specialization |

This comparison illustrates why a comprehensive solution like our filling flow divider stands out. Our focus on precision engineering, high-quality materials, broad application capability, and strong customer support provides a superior value proposition for businesses looking to optimize their automated filling machines.

Customized Solutions for Unique Requirements

Recognizing that standard solutions may not always perfectly fit every complex industrial application, we offer extensive customization options for our filling flow divider systems. Our engineering team works closely with clients to develop bespoke solutions tailored to their specific operational constraints, product characteristics, and integration needs.

Customization capabilities include, but are not limited to:

- Tailored Number of Outlets: While standard configurations range up to 16 outlets, we can engineer dividers with a higher or specific number of channels to match unique multi-head filling machine requirements.

- Specialized Material Selection: For extremely corrosive, abrasive, or high-temperature products, alternative materials such as Hastelloy, Titanium, or specific ceramic coatings can be incorporated for wetted parts to ensure longevity and chemical inertness.

- Unique Connection Types & Sizes: Beyond standard Tri-clamp or NPT, we can provide custom flange designs, specialized threaded connections, or integrate with proprietary piping systems.

- Integration with Advanced Control Systems: Our units can be designed to interface seamlessly with specific PLC models, SCADA systems, or custom HMI (Human Machine Interface) setups for enhanced control and data logging capabilities within automated filling machines.

- Optimized for Specific Viscosities/Temperatures: For products with extreme viscosity profiles (e.g., highly thixotropic fluids) or operating temperatures outside the standard range, internal geometries and sealing technologies can be modified for optimal performance.

- ATEX/Explosion-Proof Compliance: For applications in hazardous environments, our units can be specified and certified to meet ATEX directives for explosion protection.

Our approach to customized solutions ensures that every client receives a filling flow divider that is perfectly aligned with their operational objectives, maximizing efficiency, safety, and return on investment.

Real-World Application Case Studies

Our filling flow divider solutions have consistently delivered measurable improvements in efficiency, accuracy, and profitability for clients across various industries. Here are two illustrative case studies:

Case Study 1: High-Volume Sauce Bottling

Client: A leading international food manufacturer specializing in gourmet sauces and condiments.

Challenge: The client operated a high-speed, 8-nozzle automatic filling machine for various sauces (ranging from thin vinaigrettes to thick BBQ sauces). Their existing volumetric fillers suffered from inconsistent fill levels across nozzles, leading to significant product giveaway (estimated at 1.5% overfill) and frequent line stoppages for recalibration. This impacted their profitability and ability to meet strict retailer specifications for net weight.

Solution: We engineered and integrated a custom 8-outlet filling flow divider system, constructed from SS316L for hygienic processing and equipped with specialized seals to handle both acidic and viscous products. The system was calibrated for their diverse product range.

Results: Post-implementation, the client observed a dramatic improvement in filling accuracy, consistently achieving ±0.2% across all 8 nozzles. Product giveaway was reduced to negligible levels (below 0.1%), translating to annual savings of over $250,000 in raw material costs for just one product line. Line stoppages for recalibration were virtually eliminated, increasing overall equipment effectiveness (OEE) by 12% and enabling the client to meet increased production targets without additional capital expenditure.

Case Study 2: Industrial Lubricant Dispensing

Client: A major producer of specialty industrial lubricants and greases.

Challenge: The client was experiencing challenges with their existing automated filling machines for highly viscous industrial lubricants. The abrasive nature of some lubricants and the high pressures involved led to rapid wear of components, frequent leaks, and unreliable fill volumes across their 6-nozzle filling line. Maintenance costs were high, and production schedules were often disrupted.

Solution: We provided a heavy-duty, 6-outlet filling flow divider specifically designed for high-pressure, high-viscosity applications. The unit featured hardened stainless steel gears, PEEK bearings, and robust mechanical seals resistant to the aggressive chemical composition of the lubricants. Custom inlet/outlet connections were fabricated to integrate seamlessly with their existing piping.

Results: The new flow divider system immediately resolved the issues of inconsistent fills and leakage. The robust construction significantly extended the service life of the filling unit, reducing maintenance interventions by 70% within the first year. Product waste from uneven fills was cut by 95%, leading to substantial cost savings. The improved reliability contributed to a 15% increase in production line uptime, directly impacting profitability and allowing the client to take on more orders with confidence.

Commitment to Google Standards

Our dedication to providing high-quality, reliable B2B solutions is mirrored by our commitment to demonstrating Expertise, Experience, Authoritativeness, and Trustworthiness () in all aspects of our operations and content. This commitment ensures our clients receive not only superior products but also comprehensive support and transparent information.

Frequently Asked Questions (FAQ)

-

Q: How does a filling flow divider ensure equal fill volumes across multiple nozzles?

A: Our flow dividers utilize precision-machined, interlocking gears or pistons that rotate synchronously. Each rotation displaces an exact, identical volume of product into each output channel, ensuring volumetric accuracy regardless of minor pressure fluctuations in the main supply line.

-

Q: What types of products can your filling flow dividers handle?

A: Our dividers are designed for exceptional versatility, capable of handling a wide range of liquids from low-viscosity fluids like water, alcohol, and solvents to highly viscous products such as creams, pastes, gels, and even products with small particulates. Material selection for wetted parts is customized based on product compatibility.

-

Q: What is the typical maintenance schedule for a filling flow divider?

A: With proper installation and operation, our flow dividers require minimal maintenance. We recommend periodic inspection (e.g., annually) of seals and general operational checks. Depending on the product handled and operational hours, seal replacement might be required every 2-3 years. Comprehensive maintenance guidelines are provided with each unit.

Lead Time & Fulfillment Details

For standard filling flow divider models, typical lead times range from 4-8 weeks from order confirmation, subject to current production schedules. Customized solutions may require 8-12 weeks, depending on the complexity of engineering and material sourcing. We maintain transparency throughout the order fulfillment process, providing regular updates and working closely with clients to meet their project timelines. Expedited options may be available upon request.

Warranty Commitments & Customer Support

We stand behind the quality and performance of our filling flow divider products with a comprehensive 1-year warranty covering defects in materials and workmanship. Our commitment extends beyond the sale with robust after-sales support:

- Dedicated Technical Support: Access to experienced engineers for troubleshooting, technical advice, and operational guidance.

- Spare Parts Availability: A readily available inventory of genuine spare parts to minimize downtime.

- Installation & Training Support: Options for on-site installation assistance and comprehensive operator/maintenance training to ensure optimal system performance.

- Maintenance Contracts: Customized service agreements to provide proactive maintenance and extended support.

Our goal is to be a trusted partner, ensuring the long-term success and efficiency of your automated filling machines.

References

- International Organization for Standardization. ISO 9001:2015 - Quality management systems. Retrieved from ISO.org.

- American Society of Mechanical Engineers. ASME B31.3 - Process Piping. Retrieved from ASME.org.

- U.S. Food and Drug Administration. 21 CFR – Code of Federal Regulations, Title 21. Retrieved from FDA.gov.

- European Union. Directive 2014/34/EU (ATEX) - Equipment and protective systems intended for use in potentially explosive atmospheres. Retrieved from EUR-Lex.Europa.eu.

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025

-

Best Commercial Marinating Machines for Meat Processing | Efficient & ScalableNewsNov.20,2025