- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

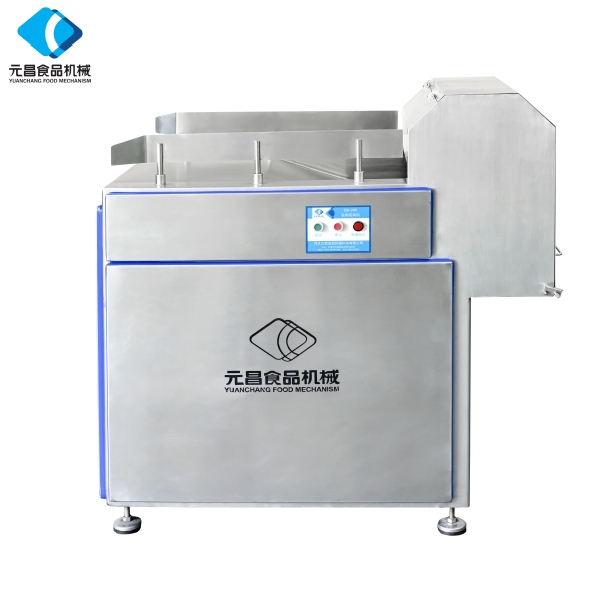

Frozen Meat Slicer – Commercial, Precise, Safe & Fast

Frozen Meat Slicer is a key solution in the Machinery and equipment industry, specifically within Food Machinery and Meat processing equipment. This article explores how Hebei Yuanchang Food Mechanism & Technology Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Frozen Meat Slicer Overview

- Benefits & Use Cases of Frozen Meat Slicer in Meat processing equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Machinery and equipment

- Conclusion on Frozen Meat Slicer from Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

Frozen Meat Slicer Overview

A Frozen Meat Slicer—often referred to as a meat slicer for frozen meat, frozen food slicer, or commercial frozen meat slicer—is engineered to cut sub-zero meat blocks, primals, and formed products into uniform slices or chunks without thawing. Within the Machinery and equipment / Food Machinery / Meat processing equipment ecosystem, this machine is a productivity cornerstone, feeding downstream grinders, mixers, bowl cutters, marinaders, and portioning lines with consistent inputs that stabilize yields and reduce manual handling risk. In high-throughput plants, consistency of slice thickness and minimal temperature rise are crucial for product quality, food safety, and process efficiency.

Technically, modern frozen meat slicers combine high-torque drives, food-grade stainless-steel construction, guarded infeed designs, and precise thickness adjustment to process a range of proteins—beef, pork, poultry, seafood—kept at frozen temperatures. Safety interlocks and washdown-ready frames support hygiene and operator protection, while robust blades and guides maintain cut accuracy across long shifts. Hebei Yuanchang Food Mechanism & Technology Co., Ltd. manufactures reliable, industrial-grade equipment built for continuous duty, aligning mechanical stability with sanitation-focused design so processors can integrate the unit seamlessly into existing lines and meet strict QA standards.

Benefits & Use Cases of Frozen Meat Slicer in Meat processing equipment

In meat and poultry facilities, a Frozen Meat Slicer is typically positioned after cold storage and before primary size reduction. Common applications include pre-sizing frozen beef or pork blocks for grinding, portioning poultry for further marination or forming, and preparing seafood blocks for value-added processing. By slicing at frozen temperatures, processors reduce drip loss, minimize microbial risk, and avoid the variability of partial thawing. The result is more predictable downstream load on grinders and mixers, tighter batch specs, and improved overall line balance.

Key advantages for B2B users include stable slice thickness, low product temperature rise, continuous feed options, and easy sanitation changeovers—vital for multi-SKU plants. Compared to ad-hoc cutting methods, a dedicated frozen meat slicer commercial unit improves labor safety and throughput while preserving protein structure. Hebei Yuanchang Food Mechanism & Technology Co., Ltd. leverages industry experience to tailor machine configurations—such as different infeed profiles, blade geometries, guards, and controls—so the frozen food slicer integrates with conveyors, hoists, or bins and meets the unique requirements of red meat, poultry, or seafood workflows.

Cost, Maintenance & User Experience

Total cost of ownership for a Frozen Meat Slicer is driven by uptime, blade life, sanitation time, and energy use. A commercial frozen meat slicer from Hebei Yuanchang Food Mechanism & Technology Co., Ltd. focuses on durable components and ergonomic access, helping reduce unplanned downtime and speeding routine maintenance. Food-grade stainless-steel frames, sealed bearings in washdown zones, and accessible cutting assemblies help teams complete cleaning and inspection efficiently—supporting compliance and faster line restarts. Over time, these factors translate into a strong ROI through reduced labor risk, better yield control, and consistent throughput that stabilizes cost per kilogram.

From a user standpoint, operators value intuitive controls, clear guarding, and repeatable thickness settings for different SKUs. Maintenance teams appreciate standard components, clear lubrication points, and straightforward blade change procedures. Feedback from Food Machinery customers often highlights improved flow to grinders and fewer stoppages due to irregular chunk sizes. Buyers evaluating a frozen meat slicer commercial solution should consider not only purchase price but also after-sales support, spare parts availability, training resources, and validation assistance—all areas where Hebei Yuanchang delivers responsive service to keep production schedules on track.

Sustainability & Market Trends in Machinery and equipment

Sustainability priorities in meat processing increasingly center on energy efficiency, waste reduction, and hygienic design. Slicing product while frozen avoids extended thawing, which can reduce drip losses and help maintain protein quality—supporting better yield and fewer off-spec materials. Efficient drives and motors, combined with optimized blade paths and reduced idle time, further contribute to lower energy intensity per kilogram processed. As regulatory expectations around sanitation, allergen control, and traceability rise, equipment that supports rapid, verifiable cleaning and clear documentation helps plants meet audit requirements without compromising throughput.

Hebei Yuanchang Food Mechanism & Technology Co., Ltd. positions its Frozen Meat Slicer line with an eco-conscious, forward-looking approach: robust stainless-steel fabrication for long service life, washdown-friendly assemblies to minimize chemical and water use, and integration readiness for smart line controls that reduce idle run and improve OEE. For processors planning capacity expansions or modernization, selecting a meat slicer for frozen meat that aligns with sustainability goals is both a compliance and brand-value decision—one that Hebei Yuanchang supports with reliable engineering and attentive after-sales service.

Conclusion on Frozen Meat Slicer from Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

In summary, a Frozen Meat Slicer is an essential asset in Machinery and equipment / Food Machinery / Meat processing equipment, delivering consistent pre-sizing, better hygiene control, and reliable throughput for high-demand plants. Hebei Yuanchang Food Mechanism & Technology Co., Ltd. combines durable construction, practical design, and responsive support to help B2B operations achieve stable yields and safer workflows. Ready to optimize your frozen processing line? Contact us: email: ycmeatmech@gmail.com. Visit our website: https://www.ycmeatmech.com

-

Filling Flow Divider - Precision, Hygienic Multiline DosingNewsNov.18,2025

-

Hopper Trolley: Heavy-Duty, Ergonomic, Easy DischargeNewsNov.18,2025

-

Frozen Meat Slicer for Ultra-Thin, Precise, Safe CutsNewsNov.17,2025

-

Smoke House Machine | Precise, Energy-Efficient, HACCP-ReadyNewsNov.17,2025

-

Smoke House Machine: Uniform, Energy-Efficient SmokingNewsNov.11,2025

-

Meat Filling Machine - Stainless, Precise, High OutputNewsNov.11,2025