- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Filling Flow Divider: Precise Multi-Line Filling—Need One?

[filling flow divider,auto filling machine,automated filling machines,automatic filling machine,filling machine] is a key solution in the Mechanical equipment manufacturing industry, specifically within Specialized equipment manufacturing and Manufacturing of specialized packaging equipment. This article explores how Hebei Yuanchang Food Mechanism & Technology Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- [filling flow divider,auto filling machine,automated filling machines,automatic filling machine,filling machine] Overview

- Benefits & Use Cases of [filling flow divider,auto filling machine,automated filling machines,automatic filling machine,filling machine] in Manufacturing of specialized packaging equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Mechanical equipment manufacturing industry

- Conclusion on [filling flow divider,auto filling machine,automated filling machines,automatic filling machine,filling machine] from Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

[filling flow divider,auto filling machine,automated filling machines,automatic filling machine,filling machine] Overview

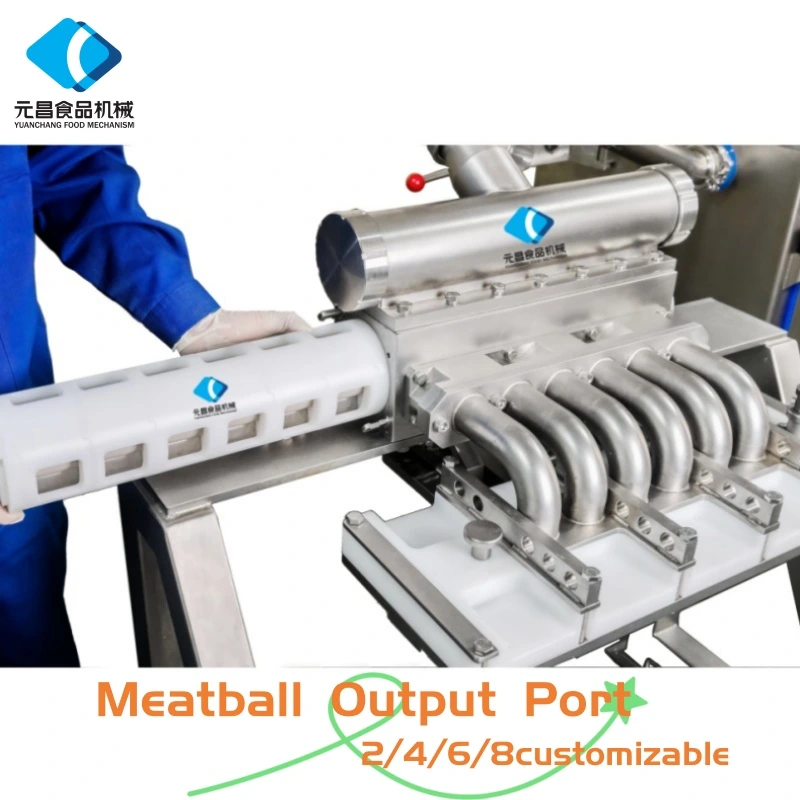

A modern filling flow divider is the heart of many automated filling machines. In specialized packaging equipment, it precisely meters viscous products and uniformly splits flow across multiple lanes for synchronized dosing and forming. As part of an auto filling machine or a standalone automatic filling machine, it ensures consistent weights, shapes, and textures—vital for high-throughput food and protein-processing applications.

Hebei Yuanchang Food Mechanism & Technology Co., Ltd. engineers a robust filling machine platform that integrates a flow-divider forming module, PLC/HMI controls, sanitary stainless-steel construction, and rapid changeover tooling. The flow path is designed for hygiene and consistent product handling, with options suited to meat emulsions, plant-based mixes, sauces, and semi-solids. With decades in specialized equipment manufacturing, Hebei Yuanchang’s focus on reliability and cleanability supports compliance with global food-safety standards while achieving high production yields.

Learn more on the product page: Filling & Flow Divider Forming Machine.

Benefits & Use Cases of [filling flow divider,auto filling machine,automated filling machines,automatic filling machine,filling machine] in Manufacturing of specialized packaging equipment

In Manufacturing of specialized packaging equipment, automated filling machines must manage diverse products and formats—from patties and meatballs to pastes, pet foods, and plant-based proteins. A filling flow divider enables multi-lane dosing with minimal giveaway, feeding tray-sealers, thermoformers, MAP lines, and rotary pouch systems. When paired with an automatic filling machine, processors can scale throughput while maintaining tight fill tolerances and repeatable forming quality.

Key advantages include streamlined changeovers, ergonomic tool-free adjustments, and integration readiness with upstream grinders/blenders and downstream conveyors, cutters, or formers. The result is continuous, stable production with fewer bottlenecks. Hebei Yuanchang Food Mechanism & Technology Co., Ltd. brings deep application expertise to configure each filling machine for media viscosity, particulate size, and line speed, helping B2B decision makers hit target capacities without sacrificing hygiene or accuracy. For lines adding a new auto filling machine, the YC design supports modular expansion and future upgrades.

Cost, Maintenance & User Experience

Total cost of ownership for an automatic filling machine is driven by uptime, product yield, sanitation time, and energy use. Hebei Yuanchang’s approach focuses on durable materials, simplified product contact parts, and accessible components, so routine cleaning and preventive maintenance are faster and less labor-intensive. Reducing product giveaway through precise metering translates directly into improved margins, especially on high-value formulations.

Users in specialized equipment manufacturing value the intuitive HMI, recipe-driven setups, and stable multi-lane synchronization provided by the filling flow divider. Maintenance teams benefit from clear service intervals, standardized wear parts, and responsive after-sales support. Across installations, customers commonly report smoother start-ups, shorter changeovers, and consistent portioning quality—key inputs to a compelling ROI for automated filling machines in high-mix, high-throughput environments.

Sustainability & Market Trends in Mechanical equipment manufacturing industry

Packaging operations are advancing toward safer, cleaner, and more efficient production. Regulations and retailer expectations emphasize hygienic design, traceability, and waste reduction. Automated filling machines with efficient drives, optimized flow paths, and clean-in-place-friendly geometries can lower water, chemical, and energy consumption per unit produced. Minimizing overfill with a precise filling machine also reduces raw-material waste.

Market trends show increasing automation, analytics-ready controls, and versatility to handle both conventional and alternative proteins. Hebei Yuanchang Food Mechanism & Technology Co., Ltd. reflects these priorities through robust engineering, recyclable stainless-steel frames, and designs that facilitate longer service life and easy refurbishments. By aligning the filling flow divider and auto filling machine platforms with evolving safety and sustainability standards, the company positions B2B manufacturers to grow responsibly while safeguarding product quality.

Conclusion on [filling flow divider,auto filling machine,automated filling machines,automatic filling machine,filling machine] from Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

For specialized packaging equipment, a well-engineered filling flow divider within an automatic filling machine delivers measurable gains in accuracy, hygiene, and throughput. Hebei Yuanchang Food Mechanism & Technology Co., Ltd. combines proven craftsmanship with application-driven design to provide a filling machine solution that scales with your production goals.

Contact us: email: ycmeatmech@gmail.com

Visit our website: https://www.ycmeatmech.com

-

Filling Flow Divider - Precision, Hygienic Multiline DosingNewsNov.18,2025

-

Hopper Trolley: Heavy-Duty, Ergonomic, Easy DischargeNewsNov.18,2025

-

Frozen Meat Slicer for Ultra-Thin, Precise, Safe CutsNewsNov.17,2025

-

Smoke House Machine | Precise, Energy-Efficient, HACCP-ReadyNewsNov.17,2025

-

Smoke House Machine: Uniform, Energy-Efficient SmokingNewsNov.11,2025

-

Meat Filling Machine - Stainless, Precise, High OutputNewsNov.11,2025