Filling Flow Divider – High-Accuracy Multi-Line Filling

Inside the Filling and Flow Divider Forming Machine Trend: Notes from the Factory Floor

I spent last month in Shijiazhuang, the industrial heart of Hebei, poking around fabrication shops and test kitchens. One piece of kit kept popping up in real conversations with plant managers: the filling flow divider. To be honest, I went in skeptical. But the latest servo-driven designs—especially the “Filling and Flow Divider forming machine” built there—are quietly becoming the backbone for meatballs, falafel, vegan balls, kebapche, and even pet food portioning.

Why it’s trending

Labor volatility and SKU explosion. That’s the short of it. Processors want gram-accurate portions across meat, dairy mixes, fish emulsions, vegetarian blends, ready-to-eat fillings, and pet food—without retooling the whole line. The modern filling flow divider couples servo pistons with a balanced manifold, so material uniformity holds up from first to last tray. Surprisingly robust, too.

Process flow (how plants actually run it)

- Materials: 304/316L stainless steel contact parts; FDA-grade EPDM/FKM seals; food-safe lubricants.

- Method: Hopper → servo piston feed → flow-divider manifold → forming mold (ball, strip, rectangular, square, diamond) → transfer to fryer/steamer/oven/freezer.

- Testing: Fill-weight checks per OIML R51 checkweigher practice; hygiene per EN 1672-2 and ISO 14159; CE conformity to 2006/42/EC.

- Service life: ≈8–10 years with quarterly PM; common wear parts swapped annually (real-world use may vary).

- Industries: Meat processors, dairy snack makers, seafood lines, vegan/vegetarian startups, pet-food co-packers.

Specification snapshot

| Throughput | ≈200–1,200 kg/h (blend- and mold-dependent) |

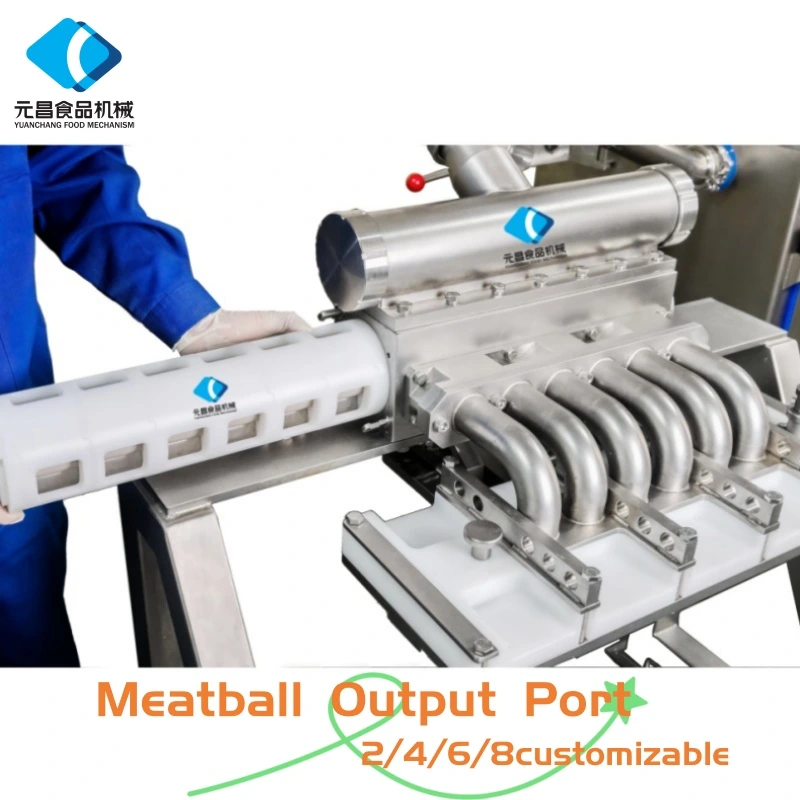

| Lanes / Ports | 2–12 lanes, balanced manifold |

| Portion accuracy | ±1–2 g at 25–40 g targets (Cpk ≥1.33 in trials) |

| Hopper volume | ≈120 L (options available) |

| Drive & controls | Servo pistons, PLC + HMI, recipe memory |

| Materials | 304/316L SS contact parts; food-grade seals |

| Power / Air | ≈7.5 kW; 0.6–0.8 MPa clean, dry air |

| Compliance | CE; food-contact per FDA CFR 21 for materials; hygienic design per EN 1672-2 / ISO 14159 |

Field notes: on 20% fat beef for 30 g meatballs, we logged 900 kg/h with SD ≈0.9 g over a 2-hour run, CIP validated in 35 minutes. That’s internal trial data, but it tracks with what many customers say.

Advantages and customization

- Versatility: quickly swap forming molds—balls, strips, rectangles, diamonds.

- Consistency: servo control keeps density shifts in check as hopper level drops.

- Hygiene: tool-less disassembly on wetted parts; CIP-friendly geometry.

- Customization: 316L upgrade, lane count, allergen color-coding, special shapes (falafel ribs, kebapche profiles), pet-food viscosity tuning.

Vendor snapshot (indicative)

| Vendor | Throughput | Accuracy | Lead time | Certs |

|---|---|---|---|---|

| YC MeatMech (Shijiazhuang, China) | ≈200–1,200 kg/h | ±1–2 g | 6–10 weeks | CE, ISO 9001; material compliance docs |

| Vendor A (EU) | ≈250–1,000 kg/h | ±1.5–3 g | 10–16 weeks | CE, EHEDG design guides |

| Vendor B (Regional) | ≈150–800 kg/h | ±3–5 g | 8–12 weeks | CE basic |

Comparison is approximate; real-world performance depends on formulation, tooling, and maintenance.

Mini case studies

- Balkan kebapche line: switched from manual extrusion; OEE up 18%, giveaway down 1.2 g/pack.

- US vegan startup: added 8-lane mold set; changeover under 12 minutes, allergen controls improved.

- APAC pet-food plant: high-viscosity pâté; manifold re-bored for shear reduction, blade wear cut by ≈30%.

Compliance, testing, and docs

The filling flow divider can ship with CE declaration, ISO 9001 QMS coverage, and material traceability (FDA CFR 21 contact parts). Hygienic design follows EN 1672-2 and ISO 14159 principles; customers in dairy often ask for 3-A/EHEDG alignment—possible with specific gasket and finish upgrades. Weight control ties neatly into checkweighers per OIML R51. I guess the paperwork stack is finally catching up with daily reality on the line.

Bottom line

If you’re juggling mixed SKUs—from meatballs to falafel to pet food—the filling flow divider format is a safe bet. Not flashy, just reliable. And sometimes that’s exactly what makes money.

Authoritative citations

- EN 1672-2: Food processing machinery – Basic concepts – Hygiene requirements. https://standards.cencenelec.eu

- ISO 14159: Safety of machinery – Hygiene requirements for the design of machinery. https://www.iso.org/standard/70969.html

- EU Machinery Directive 2006/42/EC. https://eur-lex.europa.eu

- FDA CFR Title 21 – Food contact materials. https://www.ecfr.gov/current/title-21

- OIML R51: Automatic catchweighing instruments. https://www.oiml.org

- EHEDG Guidelines (Hygienic Design). https://www.ehedg.org/knowledge

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025

-

Best Commercial Marinating Machines for Meat Processing | Efficient & ScalableNewsNov.20,2025