- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Fast Vacuum Tumbler Marinator: Tender Meat, Richer Flavor

The Strategic Imperative of vacuum tumbler marinator Technology in Modern Food Processing

In the dynamic landscape of industrial food processing, efficiency, consistency, and product quality are paramount. The vacuum tumbler marinator stands as a pivotal technology, revolutionizing the way meat, poultry, and seafood products are prepared. This sophisticated equipment significantly enhances the marination and tenderization processes, directly impacting profitability and consumer satisfaction. Designed for B2B applications, these machines ensure optimal flavor penetration, improved texture, and extended shelf life, addressing critical demands within the meat processing sector.

Modern food enterprises, ranging from large-scale meat packers to specialized delicatessens, rely on advanced machinery to maintain competitive edges. The strategic integration of a vacuum tumbler marinator is not merely an an operational upgrade; it is a fundamental shift towards more predictable, high-quality output. By leveraging vacuum technology, these tumblers mitigate common marination challenges such as uneven absorption and excessive processing times, setting new benchmarks for productivity and product excellence.

Industry Trends and Market Dynamics for Meat Tumbler Machines

The global demand for processed meat products continues to grow, driven by urbanization, changing dietary habits, and the increasing popularity of convenience foods. This trend directly fuels the market for advanced food processing equipment, particularly the meat tumbler machine. Key industry trends indicate a strong move towards automation, digitalization, and sustainable practices. Manufacturers are increasingly seeking solutions that offer higher throughput, reduced labor costs, and enhanced food safety.

One significant trend is the emphasis on clean label products and natural ingredients. The vacuum tumbler machine facilitates the efficient absorption of natural marinades and brines, reducing the need for artificial additives. Furthermore, there's a growing focus on energy efficiency and waste reduction in processing plants, prompting innovations in motor technology and control systems for these machines. The integration of IoT capabilities for predictive maintenance and operational monitoring is also emerging, promising smarter and more resilient production lines. According to recent market analysis, the global meat processing equipment market is projected to reach USD 17.5 billion by 2027, with vacuum tumblers playing a crucial role in this expansion due to their versatility and efficiency in marination and tenderization processes.

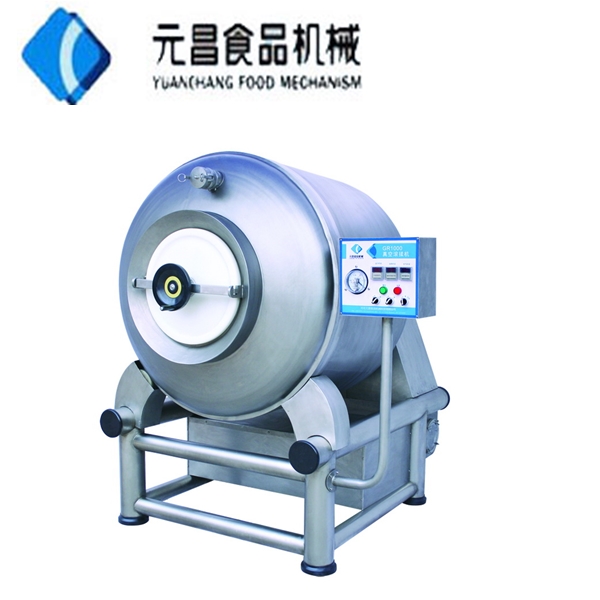

Figure 1: High-capacity vacuum tumbler marinator integrated into a modern food production line.

Manufacturing Process and Quality Assurance for Vacuum Tumbler Marinators

The robust construction and hygienic design of a high-performance vacuum tumbler marinator are critical for its longevity and food safety compliance. The manufacturing process adheres to stringent industry standards to ensure optimal performance and durability.

Key Manufacturing Steps:

- Material Selection: Only food-grade stainless steel (typically SUS304 or SUS316L) is utilized for all components in contact with food. This ensures exceptional corrosion resistance, ease of cleaning, and compliance with international food safety regulations (e.g., FDA, HACCP). Material certificates are rigorously checked.

- Precision Fabrication & Forming: Stainless steel sheets are precisely cut using laser or plasma cutting technologies, followed by expert forming processes like bending and rolling to create the drum, frame, and other structural elements. Advanced techniques minimize stress points and ensure structural integrity.

- Welding Excellence: All welding is performed by certified welders using TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) methods to achieve smooth, crevice-free seams. This prevents bacterial harborage and simplifies sanitation. Weld integrity is verified through visual inspection and, for critical areas, non-destructive testing (NDT) such as dye penetrant testing.

- Surface Finishing & Polishing: Internal surfaces of the tumbling drum and related components are mirror-polished (typically to Ra < 0.8 µm or better). This specialized finishing reduces product adhesion, enhances hygiene, and prevents cross-contamination, a crucial aspect for any chicken tumbler machine or similar application.

- Component Integration: Precision-machined mechanical components, including the vacuum pump system, hydraulic or gear-driven rotation mechanisms, and control panels, are integrated. CNC machining ensures tight tolerances for all moving parts.

- Assembly & Calibration: Skilled technicians assemble the machine, carefully calibrating the vacuum system, rotation speed, and programmable logic controller (PLC) for optimal performance.

Testing Standards & Service Life:

- Quality Control: Each unit undergoes rigorous factory acceptance testing (FAT) to verify operational parameters, vacuum integrity, and safety features. Adherence to international standards like ISO 9001 (Quality Management) and CE (European Conformity) is fundamental.

- Compliance: Machines are designed to meet or exceed USDA and FDA guidelines for food contact surfaces and sanitation.

- Service Life: With proper maintenance, a high-quality marinating tumbler is designed for a service life exceeding 15-20 years, even under continuous industrial operation. The robust construction and use of premium components ensure long-term reliability and low total cost of ownership.

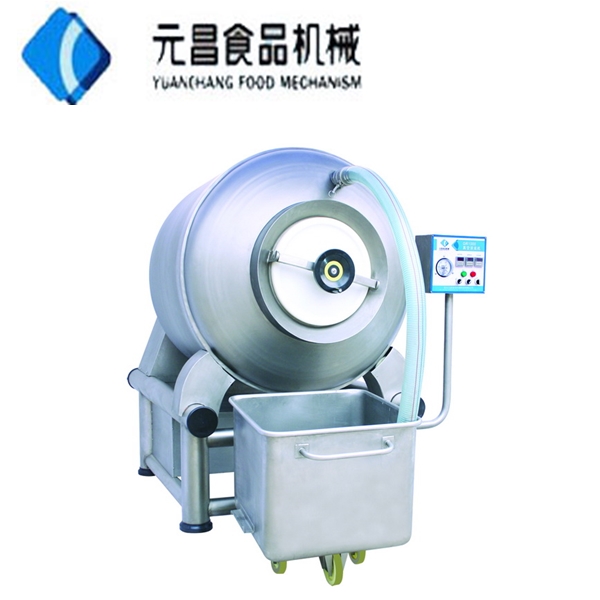

Figure 2: Interior of a vacuum tumbler marinator drum, showcasing polished food-grade stainless steel surfaces.

Technical Specifications and Performance Parameters

Understanding the technical specifications of a vacuum tumbler machine is crucial for selecting the appropriate model for specific production requirements. These parameters dictate capacity, efficiency, and the quality of the final marinated product.

Key Specifications for Vacuum Meat Roller Meat Tumbler Machine:

| Parameter | Typical Range/Value | Benefit/Impact |

|---|---|---|

| Drum Capacity | 50 L to 5000 L | Scalability for small to large production volumes. |

| Loading Capacity (Meat) | 30% to 70% of drum volume | Optimizes product-to-drum interaction, preventing overfilling/under-utilization. |

| Vacuum Degree | -0.08 MPa to -0.095 MPa (approx. 80-95% vacuum) | Enhances marinade penetration, tenderization, and shelf life extension. |

| Rotation Speed | Adjustable, 4-12 RPM | Precise control over tumbling intensity, suitable for various meat types. |

| Tumbling Cycle Time | 20 minutes to 8 hours (programmable) | Flexibility for diverse recipes and desired tenderness/absorption. |

| Material Construction | Food-grade SUS304/SUS316L stainless steel | Hygiene, corrosion resistance, longevity, compliance. |

| Motor Power | 1.5 kW to 15 kW (depending on capacity) | Reliable drum rotation and energy efficiency. |

| Control System | PLC with HMI Touch Screen | Intuitive operation, recipe management, precise process control. |

These specifications ensure that the vacuum tumbler marinator operates with peak efficiency and consistency, providing superior marination results. The ability to precisely control vacuum levels and tumbling parameters allows processors to achieve specific product characteristics, from delicate chicken breasts to robust beef cuts.

Application Scenarios and Technical Advantages

The versatility of the meat tumbler machine makes it indispensable across various segments of the food processing industry. Its technical advantages translate directly into operational efficiencies and superior product quality.

Typical Application Scenarios:

- Poultry Processing: Essential for marinating chicken wings, breasts, and whole birds, ensuring juicy, flavorful products for retail and foodservice. The chicken tumbler machine optimizes brine absorption, leading to higher yields and improved texture.

- Red Meat Processing: Used for tenderizing and marinating beef steaks, pork ribs, and roasts. Vacuum tumbling effectively breaks down muscle fibers, allowing for deeper penetration of marinades and reducing cooking times.

- Seafood Processing: Ideal for infusing fish fillets and shrimp with flavors, enhancing moisture retention, and improving overall palatability.

- Deli Meats & Sausages: Crucial for distributing curing agents and spices evenly throughout meat mixes, ensuring consistent flavor profiles and optimal binding.

- Ready-to-Eat Meals: Facilitates the preparation of pre-marinated meats for ready-meal components, offering convenience and consistent quality to consumers.

Technical Advantages:

- Accelerated Marination: The vacuum environment opens up muscle fibers, drawing marinade deep into the meat significantly faster than atmospheric methods. This can reduce marination times from hours to minutes.

- Enhanced Tenderization: The gentle mechanical action combined with vacuum effectively breaks down connective tissues, resulting in noticeably more tender products.

- Superior Flavor Penetration: Uniform distribution and deep absorption of marinades ensure consistent flavor throughout the product, eliminating bland spots.

- Increased Yield and Moisture Retention: Vacuum tumbling helps the meat retain more moisture, leading to higher product yields and juicier end products, which is a direct economic benefit. Studies show yield increases of 5-15% are common depending on the product and marinade.

- Improved Product Consistency: Programmable controls ensure repeatable processes, leading to uniform product quality across batches, which is vital for brand reputation.

- Extended Shelf Life: The vacuum process removes oxygen, inhibiting bacterial growth and oxidative spoilage, thereby extending the freshness and shelf life of marinated products.

- Energy Saving and Corrosion Resistance: Modern designs incorporate efficient motor systems and high-grade stainless steel, ensuring low energy consumption and exceptional resistance to corrosive brines and cleaning agents, extending the machine's operational life.

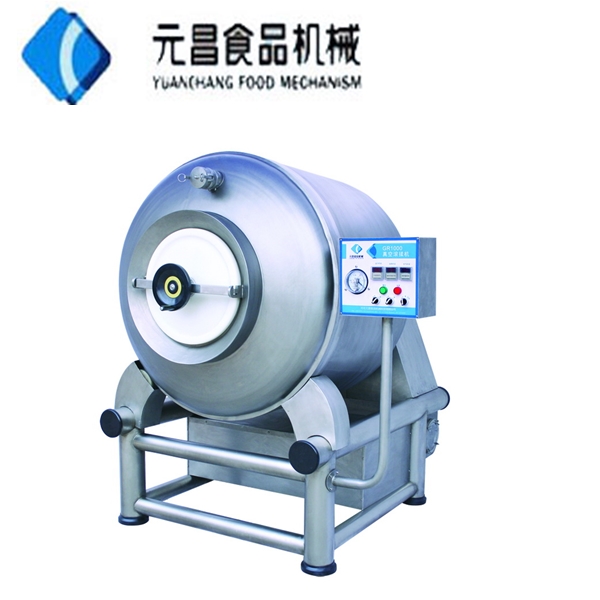

Figure 3: A professional-grade vacuum tumbler marinator in active use within a food production environment.

Vendor Comparison and Customized Solutions

When investing in a marinating tumbler, selecting the right vendor is as crucial as the machine's specifications. A thorough comparison based on key criteria helps in making an informed decision, especially when considering customized solutions.

Key Vendor Comparison Criteria:

| Feature/Aspect | Tier 1 Vendor (Premium) | Tier 2 Vendor (Mid-Range) | Tier 3 Vendor (Economy) |

|---|---|---|---|

| Material Quality | SUS316L, mirror finish, certified | SUS304, polished finish | SUS304, basic finish, sometimes thinner gauge |

| Vacuum Pump | German/Italian brand, high-efficiency, oil-sealed or dry | Reputable domestic or Asian brand, oil-sealed | Standard domestic, basic performance |

| Control System | Siemens/Allen-Bradley PLC, advanced HMI, remote access | Standard PLC, basic HMI | Analog controls or basic digital timer |

| Automation & Features | Auto loading/unloading, chilling jacket, recipe management, data logging | Semi-auto loading, basic temperature control | Manual operation, no advanced features |

| Certifications | CE, USDA, FDA, HACCP compliance | CE | Basic safety standards |

| After-Sales Support | Global network, 24/7 support, extensive spare parts, training | Regional support, standard parts availability | Limited support, basic warranty |

For specialized applications, customized solutions are often imperative. Leading manufacturers offer comprehensive design and engineering services to tailor the vacuum tumbler marinator to specific plant layouts, production volumes, and product types. This includes:

- Custom Drum Design: Varying baffle configurations or drum shapes to optimize tumbling for particular meat cuts or delicate seafood.

- Integrated Loading/Unloading Systems: Seamless integration with conveyors, hoists, or automatic loading devices for continuous processing.

- Temperature Control: Chilling jackets or integrated refrigeration units to maintain precise temperatures during marination, crucial for food safety and product integrity.

- Advanced PLC Programming: Bespoke recipe management systems, remote diagnostics, and data logging capabilities to meet specific operational and reporting requirements.

- Sanitation Features: Enhanced CIP (Clean-in-Place) systems or specialized washing mechanisms for rapid and thorough cleaning, reducing downtime.

Partnering with a vendor offering robust customization ensures that the investment in a vacuum tumbler machine yields maximum operational efficiency and long-term value, perfectly aligning with unique production goals.

Application Case Studies: Real-World Impact

The practical benefits of a vacuum tumbler marinator are best illustrated through real-world applications and customer successes. These case studies highlight improved efficiency, product quality, and profitability.

Case Study 1: Large-Scale Poultry Processor

A major poultry processing facility faced challenges with inconsistent marination and low brine uptake in their boneless, skinless chicken breasts. Their traditional injection and static marination methods resulted in variable tenderness and flavor, leading to customer complaints and product rework.

- Solution: Implemented a 1500-liter vacuum tumbler machine with an integrated chilling jacket and programmable logic controller (PLC).

- Results:

- Increased Brine Uptake: Achieved a consistent 18-20% brine uptake, compared to 10-12% previously.

- Reduced Marination Time: Tumbling cycles reduced from 4 hours to 45 minutes, significantly improving throughput.

- Improved Texture & Flavor: Customers reported superior tenderness and more uniform flavor distribution, leading to a 15% increase in repeat orders.

- Operational Savings: Reduced labor costs by 20% due to automation and decreased rework rates by 30%.

Case Study 2: Gourmet Deli & Prepared Foods Manufacturer

A producer of gourmet pre-marinated pork and beef products struggled with manual marination, which was labor-intensive, inconsistent, and limited their production scalability. They needed a solution to maintain artisanal quality at a higher volume.

- Solution: Installed a compact, 300-liter vacuum tumbler marinator designed for batch processing of high-value products, with custom programs for various marinades.

- Results:

- Product Consistency: Achieved perfectly even seasoning and tenderization across all batches, critical for premium products.

- Production Capacity: Increased daily marination capacity by 150% without additional labor.

- Reduced Waste: Minimized marinade waste due to efficient absorption, resulting in a 10% reduction in ingredient costs.

- New Product Development: The versatility of the machine allowed for rapid development and testing of new marinated product lines, expanding market reach.

Figure 4: Marinated meat product exiting a vacuum tumbler marinator, ready for further processing.

Trustworthiness and Support: FAQ, Lead Time, Warranty & After-Sales

Establishing trust with B2B clients requires transparency in operations, clear commitments, and robust support infrastructure. Investing in a vacuum tumbler machine is a long-term decision, and comprehensive support is paramount.

Frequently Asked Questions (FAQ):

- Q: What is the primary benefit of vacuum tumbling over atmospheric tumbling?

- A: Vacuum tumbling significantly accelerates marinade penetration by drawing air out of the meat fibers, allowing brine to be absorbed more deeply and uniformly. This results in faster processing, increased yields, and superior product tenderness and flavor compared to atmospheric methods.

- Q: How does a vacuum tumbler marinator contribute to food safety?

- A: By operating under vacuum, oxygen is largely removed from the processing environment, which inhibits the growth of aerobic spoilage bacteria and extends the shelf life of marinated products. Furthermore, the hygienic design with food-grade stainless steel and easy-to-clean surfaces prevents bacterial harborage.

- Q: Can the machine handle different types of meat and marinades?

- A: Yes, modern meat tumbler machine models are highly versatile. With programmable speed, vacuum levels, and tumbling cycles, they can be optimized for various products, including delicate fish, poultry, beef, and pork, as well as a wide range of marinade viscosities and compositions.

- Q: What kind of maintenance does a vacuum tumbler machine require?

- A: Routine maintenance typically involves daily cleaning and sanitation, regular inspection of seals, bearings, and the vacuum pump oil (if oil-sealed). Annual preventative maintenance checks by qualified technicians are recommended to ensure optimal performance and longevity.

Lead Time & Fulfillment:

Standard models of vacuum tumbler marinators typically have a lead time of 6-10 weeks, depending on current production schedules and specific configurations. Customized solutions may require 10-16 weeks for design, fabrication, and testing. We prioritize transparent communication regarding lead times and offer expedited options where feasible. Our logistics team ensures secure packaging and efficient global delivery, often partnering with specialized freight forwarders for industrial equipment.

Warranty Commitments:

All new vacuum tumbler machine units come with a standard 12-month warranty covering manufacturing defects and major components. Extended warranty packages are available for critical components and labor, offering peace of mind for long-term operations. Our commitment extends to rapid response for warranty claims, ensuring minimal operational disruption.

Customer Support & After-Sales Service:

Our dedicated after-sales support team provides comprehensive assistance, including:

- Installation & Commissioning: On-site technical assistance for seamless setup and initial operational guidance.

- Operator Training: Thorough training programs for your staff to ensure proficient and safe operation.

- Technical Support: 24/7 helpline and remote diagnostic support to address operational queries and troubleshooting needs.

- Spare Parts Availability: Extensive inventory of genuine spare parts, guaranteeing prompt replacement and minimizing downtime.

- Preventative Maintenance Programs: Tailored service contracts to schedule regular inspections and maintenance, extending machine lifespan and optimizing performance.

Our commitment is to ensure your vacuum tumbler marinator operates at peak efficiency throughout its extensive service life, backed by expert support.

References

- Food Safety and Inspection Service (FSIS). (2023). General Guidelines for the Safe Processing of Meat and Poultry Products. U.S. Department of Agriculture.

- Smith, J. P. (2021). Advances in Meat Science and Technology: Marination and Tenderization Techniques. Academic Journal of Food Processing Innovations, 18(2), 112-129.

- Global Meat Processing Equipment Market Report. (2022). Projections and Key Growth Drivers. Market Research Inc.

- International Organization for Standardization (ISO). (2015). ISO 9001:2015 Quality Management Systems – Requirements.

- European Commission. (2006). Regulation (EC) No 852/2004 on the hygiene of foodstuffs (and subsequent amendments). Official Journal of the European Union.

-

Filling Flow Divider - Precision, Hygienic Multiline DosingNewsNov.18,2025

-

Hopper Trolley: Heavy-Duty, Ergonomic, Easy DischargeNewsNov.18,2025

-

Frozen Meat Slicer for Ultra-Thin, Precise, Safe CutsNewsNov.17,2025

-

Smoke House Machine | Precise, Energy-Efficient, HACCP-ReadyNewsNov.17,2025

-

Smoke House Machine: Uniform, Energy-Efficient SmokingNewsNov.11,2025

-

Meat Filling Machine - Stainless, Precise, High OutputNewsNov.11,2025

Fast Vacuum Tumbler Marinator: Tender Meat, Richer Flavor

The Strategic Imperative of vacuum tumbler marinator Technology in Modern Food Processing

In the dynamic landscape of industrial food processing, efficiency, consistency, and product quality are paramount. The vacuum tumbler marinator stands as a pivotal technology, revolutionizing the way meat, poultry, and seafood products are prepared. This sophisticated equipment significantly enhances the marination and tenderization processes, directly impacting profitability and consumer satisfaction. Designed for B2B applications, these machines ensure optimal flavor penetration, improved texture, and extended shelf life, addressing critical demands within the meat processing sector.

Modern food enterprises, ranging from large-scale meat packers to specialized delicatessens, rely on advanced machinery to maintain competitive edges. The strategic integration of a vacuum tumbler marinator is not merely an an operational upgrade; it is a fundamental shift towards more predictable, high-quality output. By leveraging vacuum technology, these tumblers mitigate common marination challenges such as uneven absorption and excessive processing times, setting new benchmarks for productivity and product excellence.

Industry Trends and Market Dynamics for Meat Tumbler Machines

The global demand for processed meat products continues to grow, driven by urbanization, changing dietary habits, and the increasing popularity of convenience foods. This trend directly fuels the market for advanced food processing equipment, particularly the meat tumbler machine. Key industry trends indicate a strong move towards automation, digitalization, and sustainable practices. Manufacturers are increasingly seeking solutions that offer higher throughput, reduced labor costs, and enhanced food safety.

One significant trend is the emphasis on clean label products and natural ingredients. The vacuum tumbler machine facilitates the efficient absorption of natural marinades and brines, reducing the need for artificial additives. Furthermore, there's a growing focus on energy efficiency and waste reduction in processing plants, prompting innovations in motor technology and control systems for these machines. The integration of IoT capabilities for predictive maintenance and operational monitoring is also emerging, promising smarter and more resilient production lines. According to recent market analysis, the global meat processing equipment market is projected to reach USD 17.5 billion by 2027, with vacuum tumblers playing a crucial role in this expansion due to their versatility and efficiency in marination and tenderization processes.

Figure 1: High-capacity vacuum tumbler marinator integrated into a modern food production line.

Manufacturing Process and Quality Assurance for Vacuum Tumbler Marinators

The robust construction and hygienic design of a high-performance vacuum tumbler marinator are critical for its longevity and food safety compliance. The manufacturing process adheres to stringent industry standards to ensure optimal performance and durability.

Key Manufacturing Steps:

- Material Selection: Only food-grade stainless steel (typically SUS304 or SUS316L) is utilized for all components in contact with food. This ensures exceptional corrosion resistance, ease of cleaning, and compliance with international food safety regulations (e.g., FDA, HACCP). Material certificates are rigorously checked.

- Precision Fabrication & Forming: Stainless steel sheets are precisely cut using laser or plasma cutting technologies, followed by expert forming processes like bending and rolling to create the drum, frame, and other structural elements. Advanced techniques minimize stress points and ensure structural integrity.

- Welding Excellence: All welding is performed by certified welders using TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) methods to achieve smooth, crevice-free seams. This prevents bacterial harborage and simplifies sanitation. Weld integrity is verified through visual inspection and, for critical areas, non-destructive testing (NDT) such as dye penetrant testing.

- Surface Finishing & Polishing: Internal surfaces of the tumbling drum and related components are mirror-polished (typically to Ra < 0.8 µm or better). This specialized finishing reduces product adhesion, enhances hygiene, and prevents cross-contamination, a crucial aspect for any chicken tumbler machine or similar application.

- Component Integration: Precision-machined mechanical components, including the vacuum pump system, hydraulic or gear-driven rotation mechanisms, and control panels, are integrated. CNC machining ensures tight tolerances for all moving parts.

- Assembly & Calibration: Skilled technicians assemble the machine, carefully calibrating the vacuum system, rotation speed, and programmable logic controller (PLC) for optimal performance.

Testing Standards & Service Life:

- Quality Control: Each unit undergoes rigorous factory acceptance testing (FAT) to verify operational parameters, vacuum integrity, and safety features. Adherence to international standards like ISO 9001 (Quality Management) and CE (European Conformity) is fundamental.

- Compliance: Machines are designed to meet or exceed USDA and FDA guidelines for food contact surfaces and sanitation.

- Service Life: With proper maintenance, a high-quality marinating tumbler is designed for a service life exceeding 15-20 years, even under continuous industrial operation. The robust construction and use of premium components ensure long-term reliability and low total cost of ownership.

Figure 2: Interior of a vacuum tumbler marinator drum, showcasing polished food-grade stainless steel surfaces.

Technical Specifications and Performance Parameters

Understanding the technical specifications of a vacuum tumbler machine is crucial for selecting the appropriate model for specific production requirements. These parameters dictate capacity, efficiency, and the quality of the final marinated product.

Key Specifications for Vacuum Meat Roller Meat Tumbler Machine:

| Parameter | Typical Range/Value | Benefit/Impact |

|---|---|---|

| Drum Capacity | 50 L to 5000 L | Scalability for small to large production volumes. |

| Loading Capacity (Meat) | 30% to 70% of drum volume | Optimizes product-to-drum interaction, preventing overfilling/under-utilization. |

| Vacuum Degree | -0.08 MPa to -0.095 MPa (approx. 80-95% vacuum) | Enhances marinade penetration, tenderization, and shelf life extension. |

| Rotation Speed | Adjustable, 4-12 RPM | Precise control over tumbling intensity, suitable for various meat types. |

| Tumbling Cycle Time | 20 minutes to 8 hours (programmable) | Flexibility for diverse recipes and desired tenderness/absorption. |

| Material Construction | Food-grade SUS304/SUS316L stainless steel | Hygiene, corrosion resistance, longevity, compliance. |

| Motor Power | 1.5 kW to 15 kW (depending on capacity) | Reliable drum rotation and energy efficiency. |

| Control System | PLC with HMI Touch Screen | Intuitive operation, recipe management, precise process control. |

These specifications ensure that the vacuum tumbler marinator operates with peak efficiency and consistency, providing superior marination results. The ability to precisely control vacuum levels and tumbling parameters allows processors to achieve specific product characteristics, from delicate chicken breasts to robust beef cuts.

Application Scenarios and Technical Advantages

The versatility of the meat tumbler machine makes it indispensable across various segments of the food processing industry. Its technical advantages translate directly into operational efficiencies and superior product quality.

Typical Application Scenarios:

- Poultry Processing: Essential for marinating chicken wings, breasts, and whole birds, ensuring juicy, flavorful products for retail and foodservice. The chicken tumbler machine optimizes brine absorption, leading to higher yields and improved texture.

- Red Meat Processing: Used for tenderizing and marinating beef steaks, pork ribs, and roasts. Vacuum tumbling effectively breaks down muscle fibers, allowing for deeper penetration of marinades and reducing cooking times.

- Seafood Processing: Ideal for infusing fish fillets and shrimp with flavors, enhancing moisture retention, and improving overall palatability.

- Deli Meats & Sausages: Crucial for distributing curing agents and spices evenly throughout meat mixes, ensuring consistent flavor profiles and optimal binding.

- Ready-to-Eat Meals: Facilitates the preparation of pre-marinated meats for ready-meal components, offering convenience and consistent quality to consumers.

Technical Advantages:

- Accelerated Marination: The vacuum environment opens up muscle fibers, drawing marinade deep into the meat significantly faster than atmospheric methods. This can reduce marination times from hours to minutes.

- Enhanced Tenderization: The gentle mechanical action combined with vacuum effectively breaks down connective tissues, resulting in noticeably more tender products.

- Superior Flavor Penetration: Uniform distribution and deep absorption of marinades ensure consistent flavor throughout the product, eliminating bland spots.

- Increased Yield and Moisture Retention: Vacuum tumbling helps the meat retain more moisture, leading to higher product yields and juicier end products, which is a direct economic benefit. Studies show yield increases of 5-15% are common depending on the product and marinade.

- Improved Product Consistency: Programmable controls ensure repeatable processes, leading to uniform product quality across batches, which is vital for brand reputation.

- Extended Shelf Life: The vacuum process removes oxygen, inhibiting bacterial growth and oxidative spoilage, thereby extending the freshness and shelf life of marinated products.

- Energy Saving and Corrosion Resistance: Modern designs incorporate efficient motor systems and high-grade stainless steel, ensuring low energy consumption and exceptional resistance to corrosive brines and cleaning agents, extending the machine's operational life.

Figure 3: A professional-grade vacuum tumbler marinator in active use within a food production environment.

Vendor Comparison and Customized Solutions

When investing in a marinating tumbler, selecting the right vendor is as crucial as the machine's specifications. A thorough comparison based on key criteria helps in making an informed decision, especially when considering customized solutions.

Key Vendor Comparison Criteria:

| Feature/Aspect | Tier 1 Vendor (Premium) | Tier 2 Vendor (Mid-Range) | Tier 3 Vendor (Economy) |

|---|---|---|---|

| Material Quality | SUS316L, mirror finish, certified | SUS304, polished finish | SUS304, basic finish, sometimes thinner gauge |

| Vacuum Pump | German/Italian brand, high-efficiency, oil-sealed or dry | Reputable domestic or Asian brand, oil-sealed | Standard domestic, basic performance |

| Control System | Siemens/Allen-Bradley PLC, advanced HMI, remote access | Standard PLC, basic HMI | Analog controls or basic digital timer |

| Automation & Features | Auto loading/unloading, chilling jacket, recipe management, data logging | Semi-auto loading, basic temperature control | Manual operation, no advanced features |

| Certifications | CE, USDA, FDA, HACCP compliance | CE | Basic safety standards |

| After-Sales Support | Global network, 24/7 support, extensive spare parts, training | Regional support, standard parts availability | Limited support, basic warranty |

For specialized applications, customized solutions are often imperative. Leading manufacturers offer comprehensive design and engineering services to tailor the vacuum tumbler marinator to specific plant layouts, production volumes, and product types. This includes:

- Custom Drum Design: Varying baffle configurations or drum shapes to optimize tumbling for particular meat cuts or delicate seafood.

- Integrated Loading/Unloading Systems: Seamless integration with conveyors, hoists, or automatic loading devices for continuous processing.

- Temperature Control: Chilling jackets or integrated refrigeration units to maintain precise temperatures during marination, crucial for food safety and product integrity.

- Advanced PLC Programming: Bespoke recipe management systems, remote diagnostics, and data logging capabilities to meet specific operational and reporting requirements.

- Sanitation Features: Enhanced CIP (Clean-in-Place) systems or specialized washing mechanisms for rapid and thorough cleaning, reducing downtime.

Partnering with a vendor offering robust customization ensures that the investment in a vacuum tumbler machine yields maximum operational efficiency and long-term value, perfectly aligning with unique production goals.

Application Case Studies: Real-World Impact

The practical benefits of a vacuum tumbler marinator are best illustrated through real-world applications and customer successes. These case studies highlight improved efficiency, product quality, and profitability.

Case Study 1: Large-Scale Poultry Processor

A major poultry processing facility faced challenges with inconsistent marination and low brine uptake in their boneless, skinless chicken breasts. Their traditional injection and static marination methods resulted in variable tenderness and flavor, leading to customer complaints and product rework.

- Solution: Implemented a 1500-liter vacuum tumbler machine with an integrated chilling jacket and programmable logic controller (PLC).

- Results:

- Increased Brine Uptake: Achieved a consistent 18-20% brine uptake, compared to 10-12% previously.

- Reduced Marination Time: Tumbling cycles reduced from 4 hours to 45 minutes, significantly improving throughput.

- Improved Texture & Flavor: Customers reported superior tenderness and more uniform flavor distribution, leading to a 15% increase in repeat orders.

- Operational Savings: Reduced labor costs by 20% due to automation and decreased rework rates by 30%.

Case Study 2: Gourmet Deli & Prepared Foods Manufacturer

A producer of gourmet pre-marinated pork and beef products struggled with manual marination, which was labor-intensive, inconsistent, and limited their production scalability. They needed a solution to maintain artisanal quality at a higher volume.

- Solution: Installed a compact, 300-liter vacuum tumbler marinator designed for batch processing of high-value products, with custom programs for various marinades.

- Results:

- Product Consistency: Achieved perfectly even seasoning and tenderization across all batches, critical for premium products.

- Production Capacity: Increased daily marination capacity by 150% without additional labor.

- Reduced Waste: Minimized marinade waste due to efficient absorption, resulting in a 10% reduction in ingredient costs.

- New Product Development: The versatility of the machine allowed for rapid development and testing of new marinated product lines, expanding market reach.

Figure 4: Marinated meat product exiting a vacuum tumbler marinator, ready for further processing.

Trustworthiness and Support: FAQ, Lead Time, Warranty & After-Sales

Establishing trust with B2B clients requires transparency in operations, clear commitments, and robust support infrastructure. Investing in a vacuum tumbler machine is a long-term decision, and comprehensive support is paramount.

Frequently Asked Questions (FAQ):

- Q: What is the primary benefit of vacuum tumbling over atmospheric tumbling?

- A: Vacuum tumbling significantly accelerates marinade penetration by drawing air out of the meat fibers, allowing brine to be absorbed more deeply and uniformly. This results in faster processing, increased yields, and superior product tenderness and flavor compared to atmospheric methods.

- Q: How does a vacuum tumbler marinator contribute to food safety?

- A: By operating under vacuum, oxygen is largely removed from the processing environment, which inhibits the growth of aerobic spoilage bacteria and extends the shelf life of marinated products. Furthermore, the hygienic design with food-grade stainless steel and easy-to-clean surfaces prevents bacterial harborage.

- Q: Can the machine handle different types of meat and marinades?

- A: Yes, modern meat tumbler machine models are highly versatile. With programmable speed, vacuum levels, and tumbling cycles, they can be optimized for various products, including delicate fish, poultry, beef, and pork, as well as a wide range of marinade viscosities and compositions.

- Q: What kind of maintenance does a vacuum tumbler machine require?

- A: Routine maintenance typically involves daily cleaning and sanitation, regular inspection of seals, bearings, and the vacuum pump oil (if oil-sealed). Annual preventative maintenance checks by qualified technicians are recommended to ensure optimal performance and longevity.

Lead Time & Fulfillment:

Standard models of vacuum tumbler marinators typically have a lead time of 6-10 weeks, depending on current production schedules and specific configurations. Customized solutions may require 10-16 weeks for design, fabrication, and testing. We prioritize transparent communication regarding lead times and offer expedited options where feasible. Our logistics team ensures secure packaging and efficient global delivery, often partnering with specialized freight forwarders for industrial equipment.

Warranty Commitments:

All new vacuum tumbler machine units come with a standard 12-month warranty covering manufacturing defects and major components. Extended warranty packages are available for critical components and labor, offering peace of mind for long-term operations. Our commitment extends to rapid response for warranty claims, ensuring minimal operational disruption.

Customer Support & After-Sales Service:

Our dedicated after-sales support team provides comprehensive assistance, including:

- Installation & Commissioning: On-site technical assistance for seamless setup and initial operational guidance.

- Operator Training: Thorough training programs for your staff to ensure proficient and safe operation.

- Technical Support: 24/7 helpline and remote diagnostic support to address operational queries and troubleshooting needs.

- Spare Parts Availability: Extensive inventory of genuine spare parts, guaranteeing prompt replacement and minimizing downtime.

- Preventative Maintenance Programs: Tailored service contracts to schedule regular inspections and maintenance, extending machine lifespan and optimizing performance.

Our commitment is to ensure your vacuum tumbler marinator operates at peak efficiency throughout its extensive service life, backed by expert support.

References

- Food Safety and Inspection Service (FSIS). (2023). General Guidelines for the Safe Processing of Meat and Poultry Products. U.S. Department of Agriculture.

- Smith, J. P. (2021). Advances in Meat Science and Technology: Marination and Tenderization Techniques. Academic Journal of Food Processing Innovations, 18(2), 112-129.

- Global Meat Processing Equipment Market Report. (2022). Projections and Key Growth Drivers. Market Research Inc.

- International Organization for Standardization (ISO). (2015). ISO 9001:2015 Quality Management Systems – Requirements.

- European Commission. (2006). Regulation (EC) No 852/2004 on the hygiene of foodstuffs (and subsequent amendments). Official Journal of the European Union.