- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

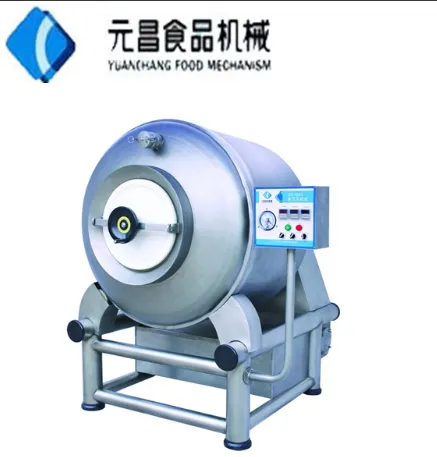

Choosing the Ideal Size of Meat Tumbler Machine

In the food processing industry, selecting the right size of meat tumbler machine, vacuum meat tumbler machine, or vacuum tumbler marinator is a crucial decision that can significantly impact production efficiency, cost - effectiveness, and the quality of the final product. Hebei Yuanchang Food Mechanism & Technology Co., Ltd. offers a diverse range of tumbler machines designed to meet various business needs.

Consider Production Volume for Meat Tumbler Machine

One of the primary factors when choosing a meat tumbler machine is the production volume. For small - scale operations with lower daily meat processing requirements, a smaller - sized meat tumbler machine may be sufficient. These compact models are ideal for processing smaller batches, allowing for more precise control over the marinating or tumbling process. On the other hand, large - scale food production facilities with high - volume demands should opt for larger meat tumbler machine models. These machines can handle substantial amounts of meat in a single cycle, reducing the overall processing time and increasing productivity. By accurately assessing the production volume, businesses can ensure that the meat tumbler machine they choose can keep up with their output needs without over - or under - utilizing resources.

Evaluate Space Availability for Vacuum Tumbler Marinator

Space availability is another key consideration, especially when it comes to installing a vacuum tumbler marinator. Before purchasing, it is essential to measure the available floor space in the processing facility. A larger vacuum tumbler marinator not only requires more floor area for installation but also needs sufficient clearance around it for easy operation and maintenance. In contrast, a smaller vacuum tumbler marinator is more suitable for kitchens or processing areas with limited space. Additionally, consider the height of the installation area, as some larger models may have height restrictions due to their design or the need to accommodate the vacuum system. By evaluating space availability carefully, customers can select a vacuum tumbler marinator that fits seamlessly into their existing setup without causing any spatial constraints.

Factor in Budget for Vacuum Meat Tumbler Machine

Budget plays a significant role in the decision - making process for a vacuum meat tumbler machine. Generally, larger and more feature - rich vacuum meat tumbler machine models come with a higher price tag. However, it is important to look beyond the initial purchase cost. Consider the long - term operational costs, such as energy consumption, maintenance expenses, and potential repair costs. A smaller vacuum meat tumbler machine may have a lower upfront cost but could end up costing more in the long run if it requires frequent repairs or consumes excessive energy. On the other hand, a larger, more efficient vacuum meat tumbler machine may offer better value for money over time, especially for businesses with high - volume production. Hebei Yuanchang Food Mechanism & Technology Co., Ltd. offers a range of vacuum meat tumbler machine options at different price points, allowing wholesalers to find models that meet their customers' budgetary requirements while still providing high - quality performance.

Meat Tumbler Machine FAQS

How do I calculate the right batch size for a Meat Tumbler Machine?

To calculate the right batch size for a meat tumbler machine, consider your daily production goals and the processing time per batch. Divide your total daily meat processing quantity by the number of batches you can realistically run in a day. Also, take into account the capacity limitations of the machine specified by Hebei Yuanchang Food Mechanism & Technology Co., Ltd. in the user manual to ensure optimal performance and even processing.

Can a small Vacuum Tumbler Marinator handle large cuts of meat?

A small vacuum tumbler marinator may have limitations when it comes to handling large cuts of meat. It is designed for smaller - sized pieces or smaller overall volumes. Large cuts may not tumble or marinate evenly in a small machine, and there is a risk of overloading the equipment. For large cuts, it is advisable to choose a vacuum tumbler marinator with a larger capacity or cut the meat into smaller, more manageable pieces.

What are the space requirements for installing a Vacuum Meat Tumbler Machine?

The space requirements for installing a vacuum meat tumbler machine include floor space for the machine itself, clearance around the machine for opening doors, accessing controls, and performing maintenance, and sufficient height to accommodate the machine and any attached vacuum components. Refer to the installation guide provided by Hebei Yuanchang Food Mechanism & Technology Co., Ltd. for specific dimensions and space recommendations for each model.

How does the size of a Meat Tumbler Machine affect energy consumption?

In general, larger meat tumbler machine models may consume more energy due to their larger motors and longer operating times for processing larger batches. However, modern machines, especially those from Hebei Yuanchang Food Mechanism & Technology Co., Ltd., are designed with energy - saving features. Smaller machines may have lower energy consumption per batch but may require more batches to process the same amount of meat, potentially offsetting the energy savings. It's important to consider the overall energy efficiency of the machine in relation to your production needs.

Does Hebei Yuanchang offer customization for Meat Tumbler Machine size?

Yes, Hebei Yuanchang Food Mechanism & Technology Co., Ltd. offers customization services for meat tumbler machine size. Wholesalers can discuss their customers' specific production, space, and budget requirements with our team. We can customize the size of the machine, including the barrel capacity, dimensions, and other features, to ensure the meat tumbler machine is the perfect fit for their unique needs.

Are you a wholesaler looking for high - quality meat tumbler machine, vacuum meat tumbler machine, and vacuum tumbler marinator? Hebei Yuanchang Food Mechanism & Technology Co., Ltd. provides a wide range of tumbler machines with various sizes and features to meet different business requirements. Our products are backed by excellent after - sales support and customization options. Contact us today to discuss your wholesale needs, request product catalogs, and start a profitable business partnership!

-

Filling Flow Divider - Precision, Hygienic Multiline DosingNewsNov.18,2025

-

Hopper Trolley: Heavy-Duty, Ergonomic, Easy DischargeNewsNov.18,2025

-

Frozen Meat Slicer for Ultra-Thin, Precise, Safe CutsNewsNov.17,2025

-

Smoke House Machine | Precise, Energy-Efficient, HACCP-ReadyNewsNov.17,2025

-

Smoke House Machine: Uniform, Energy-Efficient SmokingNewsNov.11,2025

-

Meat Filling Machine - Stainless, Precise, High OutputNewsNov.11,2025