- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

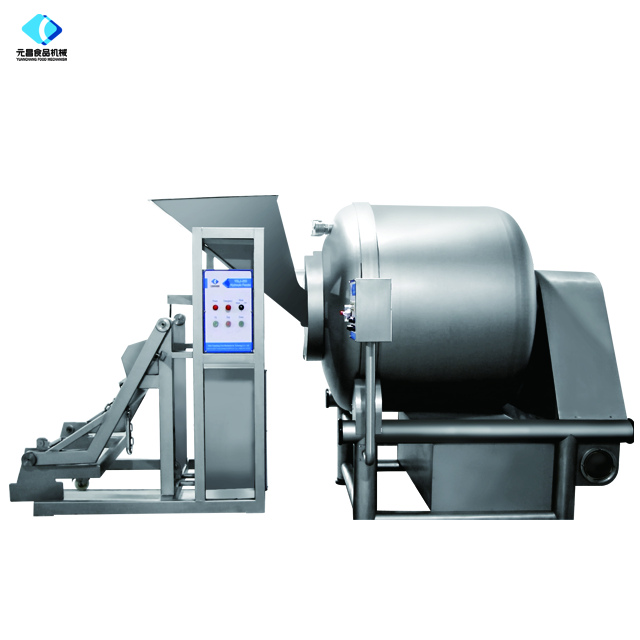

Vacuum Meat Tumbler: Fast Marinating & Tenderizing Solutions

Introduction to Advanced Meat Tumbling Technology

In the dynamic landscape of modern food processing, efficiency, consistency, and product quality are paramount. Among the critical equipment enabling these attributes, the vacuum meat tumbler stands out as a cornerstone technology. This specialized machinery is engineered to significantly enhance the marinating, tenderizing, and mixing processes for various meat products, leading to superior texture, improved flavor absorption, and extended shelf life. By operating in a vacuum environment, it mitigates oxidation, ensures deeper penetration of marinades, and reduces processing times, ultimately boosting operational output and product appeal in a highly competitive market.

This article delves into the intricate details of these indispensable machines, covering their underlying technical principles, diverse application scenarios, and the profound advantages they offer to meat processors globally. We will explore manufacturing precision, adherence to stringent quality standards, and the value proposition they present for B2B stakeholders.

Industry Trends and Market Dynamics

The global meat processing industry is undergoing significant transformation, driven by consumer demand for ready-to-eat and value-added meat products, stricter food safety regulations, and the continuous pursuit of operational efficiencies. Key trends influencing the adoption of advanced processing equipment like vacuum meat tumbler technology include:

- Increased Demand for Marinated Products: Consumers are increasingly seeking convenience and enhanced flavors, propelling growth in marinated and pre-seasoned meat segments. Vacuum tumblers are crucial for meeting this demand by ensuring rapid and uniform marinade absorption.

- Focus on Food Safety and Shelf Life: Vacuum processing minimizes bacterial growth and oxidative spoilage, aligning with stringent food safety standards and contributing to extended product shelf life, a critical factor for both producers and retailers.

- Automation and Efficiency: Labor costs and the need for consistent product quality are driving automation in meat processing. Modern meat tumbler systems offer programmable controls, reducing human error and optimizing processing cycles.

- Sustainability and Resource Optimization: Reduced processing times and more efficient marinade utilization contribute to lower energy consumption and less product waste, supporting sustainability goals within the industry.

- Traceability and Quality Control: Integrated sensor technology and data logging capabilities in advanced vacuum tumblers enable better process control and traceability, essential for compliance and brand reputation.

According to industry reports, the global meat processing equipment market is projected to grow substantially, with vacuum processing technologies playing a pivotal role due to their clear advantages in product quality and operational economics. This growth underscores the essential role of robust and reliable vacuum meat tumbler units in contemporary food production facilities.

Technical Principles and Manufacturing Process Flow

Core Technical Principles

The efficacy of vacuum tumblers is rooted in principles of mechanical action combined with controlled atmospheric pressure. The meat products, along with marinades or brines, are placed inside a rotating drum. As the drum tumbles, the meat pieces are gently massaged, lifted, and dropped. Simultaneously, a vacuum is drawn within the drum. This vacuum environment offers several key advantages:

- Enhanced Marinade Absorption: The vacuum opens the muscle fibers and pores of the meat, allowing marinades to penetrate deeper and more uniformly into the tissue. This results in superior flavor and tenderness.

- Reduced Processing Time: The accelerated absorption reduces the required marinating time significantly compared to conventional methods.

- Improved Protein Extraction: The mechanical action, particularly under vacuum, aids in the extraction of myofibrillar proteins, contributing to better bind and texture in restructured meat products.

- Minimized Oxidation: By removing oxygen from the drum, the vacuum prevents oxidative spoilage of both the meat and the marinade, preserving color, flavor, and extending shelf life.

- Tenderization: The physical impact and vacuum environment work synergistically to break down tough muscle fibers, resulting in a more tender product.

Manufacturing Process Flow of a Vacuum Meat Tumbler

The production of a high-quality vacuum meat tumbler involves a series of precision engineering and manufacturing steps, ensuring durability, hygiene, and optimal performance. The process typically adheres to international standards such as ISO 9001 for quality management.

- Material Selection: Primarily, food-grade stainless steel (e.g., SUS304 or SUS316L) is selected for all parts in contact with meat, ensuring corrosion resistance, hygiene, and compliance with food safety regulations (e.g., FDA, CE). Structural components may use high-strength carbon steel, appropriately treated for durability.

- Component Fabrication (Casting, Forging, CNC Machining):

- Drum Shell & End Plates: Typically formed from stainless steel sheets through precision bending and welding. Larger tumblers might involve specialized dished end forming.

- Vacuum Pump & Motor Housing: Often involves precision casting or machining of robust alloys to ensure airtight seals and long-term reliability.

- Internal Baffles & Scrapers: CNC machined from stainless steel to exact specifications, ensuring optimal meat agitation without damage.

- Frame & Support Structure: Constructed from heavy-gauge stainless steel profiles, often using precision laser cutting and automated welding for structural integrity.

- Sealing Components: High-grade, food-safe elastomers (e.g., silicone, EPDM) are chosen for gaskets and seals, which are critical for maintaining the vacuum. These are often molded or die-cut to precise dimensions.

- Surface Treatment & Polishing: All food-contact surfaces undergo extensive polishing to achieve a smooth, non-porous finish (e.g., Ra < 0.8 µm), preventing bacterial adhesion and facilitating easy cleaning, conforming to HACCP principles.

- Assembly: Skilled technicians assemble the various components, including the drum, drive system, vacuum system, control panel, and safety interlocks. Critical seals and bearings are carefully installed to ensure longevity and operational integrity.

- Testing Standards & Quality Assurance:

- Vacuum Leakage Test: Each unit undergoes rigorous vacuum retention tests to ensure no pressure loss over extended periods.

- Functional Test: All operational modes, rotation speeds, and control functionalities are tested under simulated load conditions.

- Electrical Safety Test: Compliance with electrical safety standards (e.g., IEC, UL) is verified.

- Noise & Vibration Analysis: Units are checked for excessive noise or vibration, indicating potential mechanical issues.

- Hygienic Design Validation: Inspection for "cleanability" and adherence to sanitary design principles (e.g., NSF/ANSI standards).

- Final Inspection & Documentation: A comprehensive final inspection is performed, and all technical documentation, including manuals and certification, is prepared.

Key Technical Parameters of a Typical Vacuum Meat Tumbler

Understanding the technical specifications is crucial for selecting the appropriate equipment for specific processing needs. Below is a table outlining typical parameters for a commercial-grade marinade tumbler:

Application Scenarios and Technical Advantages

The versatility of marinating vacuum tumblers makes them indispensable across a wide spectrum of food processing operations. Their primary target industries include:

- Meat Processing Plants: For poultry (chicken, turkey), red meat (beef, pork, lamb), and seafood, improving texture, flavor, and yield in products like cured meats, pre-marinated portions, and processed meat products.

- Ready-Meal Production: Enhancing the quality and consistency of meat components in convenience meals, ensuring optimal tenderness and flavor absorption for batch production.

- Catering Services and Institutional Kitchens: For large-scale preparation of marinated meats, ensuring consistent quality and reduced preparation time.

- Wholesale Butchers and Delicatessens: To add value to raw meat products through custom marination for specialty lines.

- Food Research & Development: For experimenting with new marinade formulations and optimizing processing parameters.

Key Technical Advantages:

- Significant Energy Savings: Modern vacuum meat tumblers are designed with highly efficient motors and optimized tumbling cycles. The rapid marinade penetration under vacuum drastically reduces the required processing time compared to atmospheric tumbling or static marination. This translates directly into lower electricity consumption per batch and higher throughput.

- Superior Corrosion Resistance: Constructed almost entirely from high-grade stainless steel (SUS304/SUS316L), these machines are inherently resistant to the corrosive effects of brines, marinades, and cleaning agents. This ensures a long operational life, reduces maintenance costs, and upholds hygienic standards crucial for food safety.

- Enhanced Product Yield and Quality: The vacuum process allows for deeper and more uniform absorption of marinades, leading to increased product weight and a juicier, more tender final product. Protein extraction is optimized, improving the binding properties for restructured products and reducing purge loss.

- Hygienic Design and Easy Cleaning: Smooth, polished internal surfaces (Ra < 0.8 µm), absence of sharp angles, and often a tiltable drum design facilitate thorough cleaning and sanitation, minimizing the risk of cross-contamination and bacterial growth. CIP (Clean-In-Place) compatibility is a common feature.

- Programmable Control and Consistency: Advanced PLC-based control systems with touchscreen HMI allow operators to set precise parameters for vacuum levels, rotation speed, dwell times, and cycle duration. This programmability ensures consistent product quality across batches, reduces reliance on manual adjustments, and facilitates quick recipe changes.

- Versatility: Capable of processing a wide variety of meat types, from delicate seafood to robust red meats, and handling diverse product forms, including whole muscles, diced meat, and poultry parts.

Vendor Comparison and Customized Solutions

Choosing the right vendor for a vacuum meat tumbler is a strategic decision that impacts long-term operational efficiency and product quality. Key factors to consider beyond initial purchase price include manufacturing quality, technology integration, after-sales support, and customization capabilities.

Vendor Comparison Considerations:

Customized Solutions for Vacuum Meat Tumblers

Recognizing that no two food processing operations are identical, leading manufacturers offer bespoke solutions for their vacuum tumblers. Customization allows businesses to perfectly integrate the equipment into existing production lines and meet unique product requirements. Common customization options include:

- Capacity Adaptation: From compact laboratory units to large industrial systems with capacities exceeding 5000 liters.

- Integrated Chilling/Heating Jackets: For precise temperature control during tumbling, crucial for specific enzymatic reactions or cold marination processes.

- Automated Loading and Unloading Systems: Hoists, conveyor belts, or pneumatic transfer systems for seamless integration into automated production lines, enhancing safety and efficiency.

- Specialized Baffle Designs: Tailored internal drum baffles for delicate products (e.g., fish fillets) requiring minimal mechanical stress, or for aggressive tumbling of tougher cuts.

- Advanced Control Systems: Integration with facility-wide SCADA systems, enhanced data logging, and remote diagnostic capabilities for industry 4.0 readiness.

- CIP (Clean-In-Place) Systems: Automated washing cycles with spray balls and drainage, ensuring optimal hygiene with minimal manual intervention.

- Multi-Functionality: Combination units that can also function as mixers for other food products, offering greater operational flexibility.

Application Case Studies and Real-World Impact

The real-world application of marinating vacuum tumblers showcases their transformative impact on product quality and operational efficiency. Here are illustrative case studies:

Case Study 1: Poultry Processing Plant - Increased Yield and Flavor

A large-scale poultry processor faced challenges in achieving consistent marinade penetration and optimal yield for their pre-seasoned chicken breast fillets. Traditional atmospheric tumblers resulted in varying flavor profiles and an average yield increase of only 12-15%.

Solution: Implemented a 1500L industrial vacuum meat tumbler with integrated chilling. The vacuum allowed for deep penetration of a complex brine solution, and precise temperature control maintained product integrity.

Results: Achieved a consistent 20-22% yield increase, significant improvement in tenderness, and a uniform flavor profile across all batches. Processing time for marination was reduced by 40%, leading to a 15% increase in daily production capacity. Customer feedback reported superior product juiciness and flavor, driving market share growth.

Case Study 2: Deli Meats Manufacturer - Enhanced Bind and Extended Shelf Life

A producer of premium cooked deli ham struggled with inconsistent protein binding in their restructured products, leading to purge loss and textural imperfections. Shelf life was also a concern due to surface oxidation during processing.

Solution: Deployed a specialized vacuum meat tumbler designed for robust protein extraction, featuring unique internal paddles and a high-efficiency vacuum pump to maintain deep vacuum throughout the tumbling cycle.

Results: Protein extraction improved by 25%, resulting in a 10% reduction in purge and significantly better binding for a firmer, more uniform slice. The vacuum environment virtually eliminated oxidation, extending the product's shelf life by an average of 5 days without chemical preservatives. This contributed to a stronger brand reputation for quality and freshness.

Case Study 3: Seafood Processor - Delicate Marination for Premium Products

A seafood company producing pre-marinated shrimp and calamari sought a gentler method to infuse flavors without damaging the delicate product structure, a common issue with aggressive tumbling.

Solution: Installed a custom-designed vacuum meat tumbler with soft, rounded baffles and highly programmable variable speed control, allowing for ultra-gentle tumbling cycles under light vacuum.

Results: Achieved uniform flavor distribution in sensitive seafood products while maintaining perfect texture and appearance. Product breakage was reduced by 90%, drastically cutting waste. The gentle vacuum processing also helped retain the natural moisture of the seafood, contributing to a premium product perception and higher selling prices.

Ensuring Quality and Reliability ( Standards)

Adherence to Google's (Expertise, Experience, Authoritativeness, Trustworthiness) framework is crucial for B2B procurement decisions. Reputable manufacturers of vacuum meat tumblers demonstrably excel in these areas.

Expertise & Authoritativeness: Certifications and Standards

- ISO 9001: Certification for Quality Management Systems, ensuring consistent product quality and continuous improvement in manufacturing processes.

- CE Mark: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area. Essential for international markets.

- FDA Compliance: Manufacturing materials and design conform to US Food and Drug Administration guidelines for food contact surfaces, crucial for processors targeting the North American market.

- HACCP & NSF/ANSI Standards: Design principles that facilitate hygienic operation and easy sanitation, supporting Hazard Analysis and Critical Control Points protocols.

- Extensive R&D: Commitment to innovation through ongoing research and development in mechanical engineering, vacuum technology, and food science to continually improve equipment performance.

Experience & Trustworthiness: Customer Feedback and Partnerships

Reputable manufacturers accumulate years of service and a robust portfolio of satisfied clients, reflecting their experience and trustworthiness. Testimonials and long-term partnerships with leading food brands underscore their proven track record. For instance, a vendor serving the industry for over 20 years, with installations in hundreds of facilities globally, provides tangible evidence of reliability.

"Implementing the YC Meat Mech vacuum meat tumbler transformed our operations. We saw immediate improvements in product consistency and a measurable reduction in processing time. Their technical support team was instrumental during setup and continues to be highly responsive."

— Production Manager, Global Meat Snacks Company

Frequently Asked Questions (FAQ)

Q: What is the primary benefit of a vacuum meat tumbler over traditional marination methods?

A: The main advantage is significantly faster and more uniform marinade penetration due to the vacuum effect, which opens up muscle fibers. This leads to enhanced flavor, improved tenderness, higher yield, and reduced processing time, while also minimizing oxidation for extended shelf life.

Q: How does a marinade tumbler contribute to food safety?

A: By operating under vacuum, oxygen is largely removed, which inhibits the growth of aerobic bacteria and reduces oxidative degradation. Furthermore, high-quality units are constructed from food-grade stainless steel with polished surfaces and designed for easy cleaning (CIP compatible), meeting stringent hygiene standards like HACCP and NSF/ANSI.

Q: Can these vacuum tumblers handle different types of meat and poultry?

A: Yes, modern vacuum tumblers are highly versatile. They can process various meats including beef, pork, poultry, lamb, and seafood. Adjustable rotation speeds, vacuum levels, and specialized baffle designs allow for gentle tumbling of delicate products and more aggressive action for tougher cuts, ensuring optimal results for a wide range of applications.

Q: What is the typical service life of a well-maintained industrial meat tumbler?

A: With proper routine maintenance, including lubrication, seal checks, and timely replacement of wear parts, a high-quality industrial vacuum meat tumbler can have an operational service life of 10 to 15 years, and often even longer. This longevity ensures a strong return on investment.

Procurement and Support Information

Lead Time and Fulfillment

Typical lead times for standard vacuum meat tumbler models range from 4 to 8 weeks, depending on current production schedules and specific configurations. Customized solutions may require 10-16 weeks for design, fabrication, and testing. Manufacturers often provide detailed project timelines and maintain transparent communication regarding fulfillment milestones. Expedited manufacturing options may be available for urgent requirements, subject to additional charges.

Warranty Commitments

Leading suppliers typically offer a comprehensive warranty, often ranging from 12 to 24 months, covering manufacturing defects and major components. Extended warranty programs are also frequently available. This commitment underscores confidence in product quality and provides peace of mind for buyers regarding potential manufacturing or material issues during initial operation.

Customer Support and After-Sales Service

Exceptional after-sales support is a hallmark of reliable vendors. This includes:

- Technical Assistance: Accessible expert support via phone, email, or dedicated online portals for troubleshooting and operational guidance.

- Spare Parts Availability: A readily available inventory of genuine spare parts to minimize downtime and ensure continuous operation.

- Installation and Commissioning: On-site technical assistance for seamless installation and initial startup, ensuring optimal machine calibration and integration.

- Training Programs: Comprehensive training for client operators and maintenance staff to ensure proficient and safe operation of the vacuum meat tumbler.

- Preventive Maintenance Contracts: Optional service agreements designed to extend equipment life and maintain peak performance through scheduled inspections and maintenance.

Conclusion

The vacuum meat tumbler is more than just a piece of equipment; it is a strategic investment for any serious meat processor aiming to achieve superior product quality, enhance operational efficiency, and maintain stringent food safety standards. Its ability to uniformly marinate, tenderize, and mix under controlled vacuum conditions offers unparalleled advantages in flavor development, texture improvement, and shelf life extension. By choosing a reputable manufacturer that adheres to the highest standards of engineering, offers robust technical support, and provides customizable solutions, businesses can unlock significant competitive advantages in the evolving food industry landscape.

The continued evolution of vacuum tumblers, driven by advancements in automation and material science, ensures that these machines will remain at the forefront of meat processing technology, delivering consistent value and innovation for years to come.

References

- Smith, J. P. (2018). "Advances in Meat Processing Technology." Food Science & Technology Journal, 25(3), 187-195.

- International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems - Requirements.

- Food and Drug Administration. (2022). Guidance for Industry: Control of Listeria monocytogenes in Ready-To-Eat Foods.

- European Committee for Standardization. (2006). EN 1672-2: Food processing machinery - Basic concepts - Part 2: Hygiene requirements.

- National Sanitation Foundation. (2023). NSF/ANSI 3-A 14159-1-2023 - Hygiene requirements for the design of meat and poultry processing equipment.

-

Filling Flow Divider - Precision, Hygienic Multiline DosingNewsNov.18,2025

-

Hopper Trolley: Heavy-Duty, Ergonomic, Easy DischargeNewsNov.18,2025

-

Frozen Meat Slicer for Ultra-Thin, Precise, Safe CutsNewsNov.17,2025

-

Smoke House Machine | Precise, Energy-Efficient, HACCP-ReadyNewsNov.17,2025

-

Smoke House Machine: Uniform, Energy-Efficient SmokingNewsNov.11,2025

-

Meat Filling Machine - Stainless, Precise, High OutputNewsNov.11,2025