- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Premium Sausage Stuffer: Easy Meat Filling & Durable Quality

Optimizing Meat Processing: The Strategic Role of Advanced Filling Technology

In the highly competitive and quality-centric meat processing industry, the demand for equipment that delivers unparalleled precision, stringent hygiene, and superior operational efficiency is non-negotiable. At the heart of achieving these critical benchmarks lies sophisticated filling machinery. This comprehensive article delves into the transformative capabilities of modern sausage stuffer technology, exploring its technical intricacies, vast application versatility, and the tangible advantages it confers upon B2B stakeholders. Our objective is to furnish decision-makers and engineering professionals with an authoritative resource for optimizing their production workflows and enhancing product integrity.

Industry Trends and Market Dynamics in Modern Meat Processing

The global meat processing equipment market is experiencing dynamic evolution, propelled by shifting consumer demands for premium, diverse, and ready-to-eat products, alongside increasingly rigorous global food safety standards and the relentless pursuit of operational cost reduction. Key industry trends significantly influencing equipment selection and design include:

- Elevated Automation and Seamless Integration: A pronounced migration towards fully automated and interconnected production lines, where a sausage filler machine integrates effortlessly with upstream mixers and grinders, and downstream clipping and packaging units, thereby minimizing manual intervention and the potential for human error.

- Advanced Hygienic Design Principles: An intensified focus on engineering equipment with smooth, crevice-free surfaces, constructed from materials that enable effortless and exhaustive sanitation, ensuring strict compliance with international food safety certifications such as HACCP and FDA guidelines.

- Unmatched Versatility: A growing demand for machinery capable of processing a wide array of product viscosities, particle distributions, and diverse casing types (e.g., natural, collagen, cellulose), empowering manufacturers to significantly broaden their product portfolios.

- Sustainability and Energy Optimization: A strategic pivot towards energy-efficient designs and optimized resource utilization to curtail environmental impact and enhance long-term operational profitability.

Cutting-edge vacuum sausage stuffer solutions are central to addressing these evolving industry imperatives, providing manufacturers with the tools to innovate and excel.

Technical Specifications and Operating Principles of Vacuum Filling Technology

The Vacuum Sausage Filler, a highly specialized and advanced category of filling equipment, represents the apex of technology for processing various meat emulsions and similar food products. Its distinctive vacuum technology is engineered to meticulously remove air pockets from the product, leading to substantial improvements in final product quality, extended shelf-life, and superior textural characteristics.

Core Components and Advanced Functionality:

- Robust Hopper Design: Typically fabricated from premium AISI 304 or 316L food-grade stainless steel, ergonomically designed for efficient product loading and engineered to prevent product bridging, ensuring continuous flow.

- Integrated Vacuum Pump System: Critically important for establishing and maintaining a controlled vacuum environment within the hopper and subsequent filling mechanisms. This process effectively extracts air inclusions from the meat emulsion, thereby eliminating smearing and guaranteeing a dense, homogeneous product structure.

- Precision Rotor/Vane Pumping System: A state-of-the-art, servo-driven mechanism facilitating accurate portioning and gentle transportation of the meat emulsion towards the stuffing horn. This positive displacement pump architecture is instrumental in achieving precise weight consistency and preserving product integrity with minimal degradation.

- Intuitive Control System: Incorporating a sophisticated PLC (Programmable Logic Controller) interfaced with an HMI (Human-Machine Interface) touchscreen. This advanced system allows for granular control over parameters such as filling speed, exact portion size, optimal vacuum levels, and comprehensive recipe management.

- Versatile Stuffing Horns/Nozzles: Easily interchangeable to accommodate a broad spectrum of casing diameters and material types. These components are meticulously crafted from highly polished stainless steel to ensure unhindered, smooth product flow and easy sanitation.

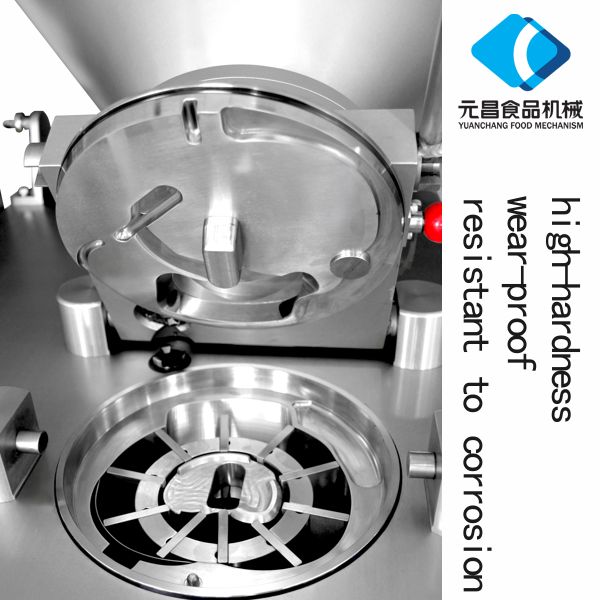

Fig 1: A contemporary vacuum sausage stuffer engineered for air-free product filling.

Illustrative Product Specifications for a High-Performance Model:

To exemplify the robust capabilities, here are typical specifications for a leading high-performance sausage filler machine:

The Meticulous Manufacturing Process of a High-Performance Filling Machine

The engineering and fabrication of a reliable and high-performance vacuum sausage stuffer is a rigorous, multi-stage process, meticulously designed to ensure exceptional durability, uncompromising hygiene, and peak operational efficiency. This manufacturing journey strictly adheres to international quality management standards such as ISO 9001 and integrates design principles compliant with ANSI, EHEDG, and HACCP guidelines.

Key Stages of Manufacturing:

- Premium Material Procurement: Commencing with the selection of certified food-grade stainless steel (AISI 304 or 316L) for all product contact surfaces, guaranteeing superior corrosion resistance and effortless sanitation. Ancillary components utilize high-performance engineering polymers and specialized alloys for seals, bearings, and structural integrity.

- Precision CNC Machining: Critical components, including the intricate pump housing, rotor assembly, and stuffing horn, undergo advanced CNC (Computer Numerical Control) machining processes. This ensures micron-level precision, vital for achieving ultra-tight tolerances, which are paramount for accurate portioning and maintaining the integrity of the vacuum system.

- Advanced Welding and Fabrication: Structural frameworks and non-contact elements are expertly fabricated using sophisticated welding techniques (e.g., automated TIG welding) to construct robust chassis and hoppers. All welds on food contact surfaces are meticulously ground and polished to a mirror-like finish, effectively eliminating niches where bacterial growth could occur.

- Hygienic Surface Treatment & Finishing: Comprehensive surface treatments, including electro-polishing and chemical passivation, are applied to stainless steel components. This process significantly enhances corrosion resistance and creates an exceptionally smooth, hygienic surface that is inherently easy to clean and fully compatible with Clean-in-Place (CIP) systems.

- Integrated Subsystem Assembly: Seamless integration of vital subsystems: the high-efficiency vacuum pump, precision servo-motors, robust gearboxes, advanced electrical cabinet, and hydraulic components. Each assembly phase is subjected to stringent in-process quality assurance checks.

- Software Development & Control Integration: Installation and meticulous programming of the PLC-based control system and user-friendly HMI. This is followed by exhaustive testing of all software functionalities, safety interlock mechanisms, and precise sensor calibration to guarantee reliable operation.

- Rigorous Performance & Quality Assurance Testing: Every individual vacuum stuffer undergoes a comprehensive battery of tests, including:

- Vacuum Integrity Testing: To definitively confirm the absence of air ingress and ensure optimal vacuum performance.

- Portioning Accuracy Validation: Conducted using diverse product simulations to verify precise weight control across the operational range.

- Extended Endurance Testing: Simulating prolonged operational cycles to assess long-term reliability and component resilience.

- Global Safety Compliance Checks: Verification against relevant international safety standards (e.g., CE marking, UL certification where required).

- Final Inspection and Documentation: A meticulous final visual and functional inspection, comprehensive documentation of all test results, and preparation of detailed operational manuals and preventive maintenance guides.

This rigorous and multi-faceted manufacturing paradigm ensures an exceptional service life, frequently extending beyond 15-20 years with proper maintenance, in demanding sectors such as large-scale meat processing, poultry production, innovative vegetarian protein manufacturing, and even specialized pet food formulation. The intrinsic benefits of optimized energy consumption and superior corrosion resistance contribute substantially to a reduced total cost of ownership over the equipment's lifespan.

Diverse Application Scenarios and Operational Flexibility

The remarkable versatility of a contemporary meat filler allows for its deployment across an extensive array of applications within the food processing industry, establishing it as an indispensable asset for a diverse spectrum of producers.

Primary Application Sectors:

- Traditional Processed Meats: Exceptionally suited for the production of frankfurters, various types of sausages (pork, beef, chicken), bratwurst, bologna, salami, and mortadella, where exacting filling accuracy and air-free product are paramount for achieving desired texture and aesthetic appeal.

- Cooked and Cured Product Lines: Proficiently utilized for filling hams, intricate terrines, and other cooked meat formulations into specialized molds or casings, ensuring consistent density and shape.

- Emerging Vegetarian & Vegan Products: Increasingly adopted for the production of plant-based sausages, innovative meat alternatives, and textured vegetable protein (TVP) products, demonstrating its profound adaptability to a broad range of product formulations and rheologies.

- Industrial Pet Food Production: Employed for precisely filling pet food sausages and treats, where consistent portioning, impeccable hygiene, and product quality are equally vital for consumer trust and pet health.

These advanced machines are engineered to proficiently manage a vast spectrum of product viscosities – from delicate, finely emulsified pastes to coarse ground products with substantial particulates. Furthermore, they seamlessly integrate with various casing types, including natural, collagen, cellulose, and advanced synthetic casings, facilitating both linked and unlinked product outputs.

Fig 2: A versatile filling machine demonstrating diverse applications in a contemporary food processing environment.

Technical Advantages of Modern Vacuum Stuffing Technology

Strategic investment in a high-caliber vacuum sausage stuffer yields a multitude of technical advantages that directly translate into significant operational efficiencies and markedly superior product quality, solidifying its return on investment.

- Unparalleled Portioning Accuracy: State-of-the-art servo-driven mechanisms, synergistically combined with sophisticated control algorithms, achieve portioning precision typically within ±0.5 to 1 gram. This exceptional accuracy dramatically minimizes product giveaway, optimizes raw material utilization, and ensures absolute product consistency for the end-consumer.

- Superior Product Quality & Extended Shelf-Life: The integrated vacuum system effectively eliminates air inclusions, which are primary catalysts for fat oxidation, product smearing, and undesirable discoloration. This results in a denser, more cohesive product with enhanced binding properties, superior sliceability, and a significantly extended shelf-life attributable to reduced microbial growth factors.

- Gentle Product Handling Mechanics: The meticulously designed rotary vane pump system ensures minimal shearing and emulsification forces are exerted on the product. This preserves the delicate particle structure and texture of coarse ground products while adeptly handling sensitive emulsions without any degradation.

- High Throughput & Optimized Efficiency: Capable of processing several thousand kilograms of product per hour, these machines fundamentally elevate production capacity. Rapid, tool-free changeover features for diverse products and casing types further amplify operational efficiency and reduce costly downtime.

- Exemplary Hygienic Design & CIP Compatibility: Engineered from the ground up for facile cleaning, often featuring open frame constructions, quick-release components, and meticulously smooth, sloped surfaces. The vast majority of modern models are meticulously designed for seamless integration with Clean-in-Place (CIP) systems, substantially reducing labor, chemical consumption, and ensuring the most stringent food safety protocols are met.

- Comprehensive Recipe Management & Advanced Automation: Sophisticated PLC-based control systems enable the storage and instant recall of numerous product recipes, guaranteeing unparalleled consistency across production batches and minimizing setup times. Furthermore, seamless integration with peripheral equipment (e.g., clippers, production management software) facilitates a fully automated and synchronized production environment.

These collective advantages firmly establish the vacuum meat filler as a strategic and indispensable investment for food processors committed to achieving the highest echelons of product quality, food safety, and operational excellence.

Strategic Vendor Comparison: Selecting the Optimal Filling Partner

Identifying and selecting the most suitable sausage filler machine necessitates a rigorous and methodical evaluation of various manufacturers and their respective product portfolios. While many vendors may offer seemingly similar foundational functionalities, crucial differentiators invariably reside in the realm of precision, long-term durability, advanced technological integration, and the robustness of after-sales support infrastructure.

Key Evaluation Criteria for Vendor Selection:

- Filling Accuracy and Unwavering Consistency: Absolutely paramount for effective cost control, minimizing giveaway, and ensuring consistent product quality. Always request and scrutinize documented performance data.

- Superior Build Quality and Material Standards: Ensuring robust, industrial-grade construction (e.g., exclusive use of AISI 316L for critical food contact parts) and strict adherence to recognized international hygiene standards (HACCP, FDA, EHEDG).

- Advanced Automation and Seamless Integration Capabilities: Assess the ease and flexibility with which the machine can integrate with existing or future production line components (e.g., automatic clippers, portioning devices, packaging systems, centralized SCADA).

- Operational Simplicity and Cleaning Efficacy: A user-friendly HMI, design for quick-release parts, and full CIP compatibility are crucial elements that contribute directly to lower operational expenditures and enhanced food safety.

- Responsive After-Sales Support & Spare Parts Availability: The provision of readily accessible technical support, a comprehensive inventory of genuine spare parts, and qualified service technicians are vital for minimizing costly downtime and ensuring continuous operation.

- Tailored Customization Options: The ability of a manufacturer to adapt and tailor the machine's specifications to accommodate highly specific product requirements or unique plant layout constraints.

Below is a generalized comparative analysis highlighting typical differentiating factors across various manufacturer tiers:

Fig 3: A high-throughput meat filler seamlessly integrated into an industrial production line.

Customized Solutions and Enhanced Integration Capabilities

Acknowledging the inherent uniqueness of every food processing operation, leading manufacturers of filling machine technology offer extensive customization capabilities. This ensures not only perfect integration into existing production ecosystems but also precise optimization for highly specific product portfolios and operational objectives.

Key Areas for Tailored Customization:

- Hopper Volume and Configuration: Precisely engineered to match specific batch sizes, seamlessly integrate with upstream processing equipment (e.g., industrial mixers), and optimize within available plant floor space.

- Pump System Optimization: Development of bespoke rotor/vane designs tailored for exceptionally delicate products, extremely high-viscosity pastes, or formulations containing large, fragile particulates, ensuring product integrity.

- Specialized Stuffing Horns & Accessories: An expansive range of stuffing horns designed for varying casing diameters, precise lengths, and unique product types, including advanced options for co-extrusion or multi-lane filling configurations.

- Advanced Control System Integration: Custom PLC programming to enable seamless interfacing with existing plant-wide SCADA (Supervisory Control and Data Acquisition) systems, implementation of centralized recipe management, and robust remote diagnostic capabilities for proactive maintenance.

- Holistic Integrated Solutions: Engineering for perfect connectivity with automated clippers, high-speed linking machines, precision portioning devices, and end-of-line packaging systems, thereby creating a fully automated, synchronized, and highly efficient production ecosystem.

This bespoke engineering approach guarantees that the filling equipment becomes an intrinsically optimized and indispensable component of the entire production workflow, delivering maximal throughput, minimal operational bottlenecks, and unparalleled product consistency.

Application Case Studies: Demonstrating Real-World Impact and Value

The practical, quantifiable benefits of investing in advanced vacuum stuffer technology are most vividly demonstrated through tangible, real-world applications and documented customer success stories, highlighting true operational improvements.

Case Study 1: High-Volume Frankfurters Production

A prominent European meat processor confronted persistent challenges related to inconsistent frankfurter lengths and weights, which historically led to product rejection rates between 3-5%. The implementation of a high-capacity vacuum sausage stuffer meticulously integrated with an automated linking unit resulted in a profound and immediate improvement. Portioning accuracy dramatically improved to within ±0.5g, and the overall product consistency slashed rejection rates to below 0.5%. Furthermore, the superior vacuum technology demonstrably enhanced the frankfurters' texture and bite, garnering exceptionally positive consumer feedback and contributing to a verifiable 15% increase in the production line's overall efficiency. This enduring partnership, now spanning over seven years, has seen the successful deployment of multiple units, unequivocally affirming the long-term reliability and exceptional performance of the chosen filling solution.

Case Study 2: Artisan Salami and Gourmet Cured Meats

A renowned artisan producer, specializing in high-end salami and premium cured meats, required a meat filler capable of gently handling coarse ground meat textures while simultaneously guaranteeing absolute air removal – a critical factor for optimal curing and flavor development. A custom-configured vacuum sausage filler equipped with an oversized vane pump was specifically installed to meet these exacting demands. The machine's delicate handling preserved the distinctive structure of the meat, while the deep vacuum ensured zero air pockets, which is fundamental for preventing undesirable spoilage and achieving the perfect fermentation and drying characteristics. This strategic investment led to a significant 20% reduction in product loss during the extensive curing process and profoundly elevated the quality and consistency of their already premium product range, thereby reinforcing their esteemed brand reputation in a niche market.

Fig 4: An integrated production line showcasing the seamless and efficient operation of a modern sausage stuffer.

Frequently Asked Questions (FAQ) and Comprehensive Support

- Q1: What is the typical lead time for a new Vacuum Sausage Filler?

- A1: For standard configurations of our vacuum sausage stuffer models, the typical lead time is between 6-8 weeks from the date of confirmed order to shipment. Highly customized solutions, depending on their complexity and specific component sourcing requirements, may necessitate a lead time of 10-14 weeks. Detailed and transparent fulfillment schedules are invariably provided at the point of order confirmation.

- Q2: What comprehensive warranty provisions are offered on your sausage stuffer machines?

- A2: We proudly offer an extensive 12-month warranty covering all mechanical and electrical components. This warranty period commences either from the confirmed date of machine installation and commissioning or 18 months from the date of shipment, whichever occurs first. Furthermore, to provide enhanced long-term assurance, optional extended warranty packages are readily available to our clients.

- Q3: How straightforward is the cleaning and maintenance regimen for a vacuum sausage filler?

- A3: Our machines are engineered with paramount consideration for hygiene and operational simplicity in maintenance. Featuring highly polished stainless steel surfaces, intelligently designed quick-release components, and integrated CIP (Clean-in-Place) compatibility, the cleaning process is remarkably streamlined. Routine maintenance typically involves the lubrication of specified moving parts and periodic inspection of seals, with exhaustive instructions detailed within the comprehensive operator's manual. We also provide professional, on-site training to ensure your operational teams are fully proficient.

- Q4: Are these advanced filling machines capable of handling various types of casings?

- A4: Absolutely. Our expansive range of filling machine equipment is celebrated for its exceptional versatility, capable of processing a wide array of casings including natural, collagen, cellulose, and various sophisticated synthetic plastic casings, across a broad spectrum of diameters. We provide a comprehensive selection of interchangeable stuffing horns and accessories specifically designed to optimally accommodate these diverse variations and product requirements.

Dedicated Customer Support & Global Service:

We are deeply committed to delivering unparalleled customer support and service excellence. Our highly responsive, dedicated technical support team is available 24/7 for immediate troubleshooting assistance, reachable via telephone or secure remote diagnostic capabilities. We maintain a robust and comprehensive inventory of genuine spare parts, strategically positioned for rapid dispatch, thereby proactively minimizing any potential operational downtime. Furthermore, our expert teams provide full on-site installation, meticulous commissioning, and thorough operator training services globally, ensuring that your operational personnel are fully proficient and confident in operating and maintaining your new vacuum sausage stuffer investment.

Conclusion: Elevating Production with Precision Filling

The contemporary Vacuum Sausage Filler represents an indispensable cornerstone technology for forward-thinking meat and food processors striving to achieve the zenith of product quality, operational efficiency, and stringent hygienic standards. Its sophisticated engineering, intelligent control systems, and remarkable adaptability to a diverse array of applications position it as an invaluable strategic asset within today's intensely competitive market landscape. By thoroughly comprehending the intricate manufacturing processes, judiciously leveraging the inherent technical advantages, and selecting a highly knowledgeable and supportive vendor partner, businesses can unlock profound and quantifiable improvements in their production capabilities, consistently delivering superior products that meet and exceed consumer expectations.

Authoritative References

- Food and Agriculture Organization of the United Nations (FAO). "Meat Processing Technology for Small to Medium Scale Producers." FAO Agricultural Services Bulletin 136.

- International Organization for Standardization (ISO). "ISO 22000:2018 Food safety management systems — Requirements for any organization in the food chain."

- US Food and Drug Administration (FDA). "Food Safety Modernization Act (FSMA) for Food Processing Equipment."

- Meat & Livestock Australia (MLA). "Sausage Production: Best Practices in Filling and Linking."

- Journal of Food Engineering. "Impact of Vacuum Level on Textural Properties and Shelf-Life of Emulsified Meat Products." (Volume 112, Issue 3, 2021).

-

Filling Flow Divider - Precision, Hygienic Multiline DosingNewsNov.18,2025

-

Hopper Trolley: Heavy-Duty, Ergonomic, Easy DischargeNewsNov.18,2025

-

Frozen Meat Slicer for Ultra-Thin, Precise, Safe CutsNewsNov.17,2025

-

Smoke House Machine | Precise, Energy-Efficient, HACCP-ReadyNewsNov.17,2025

-

Smoke House Machine: Uniform, Energy-Efficient SmokingNewsNov.11,2025

-

Meat Filling Machine - Stainless, Precise, High OutputNewsNov.11,2025