Meat Processing Equipment - Efficient, Hygienic, Affordable

Cutting Rib Machine: a practical insider’s take on modern automation

In the last five years, meat processing equipment has jumped from “reliable stainless hardware” to networked, data-aware workhorses. To be honest, plants don’t buy machines anymore—they buy throughput, yield stability, and fewer line stoppages. From what I keep hearing on floors in Hebei, Iowa, and Łódź, the gear that wins is the gear that cuts consistently and cleans down fast.

What this machine is really about

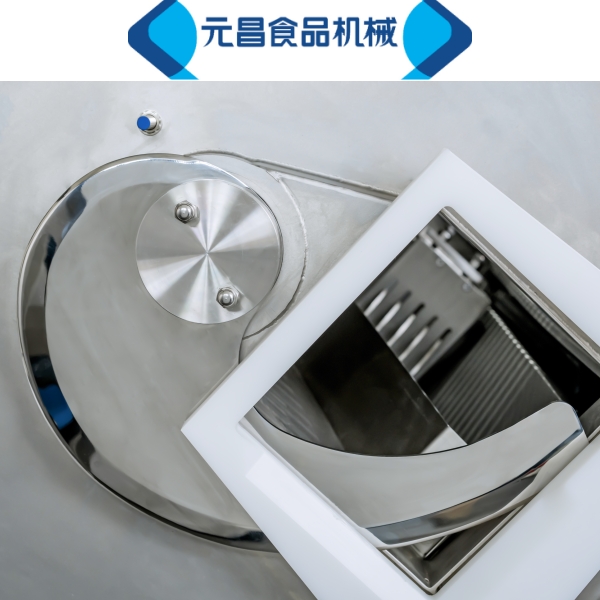

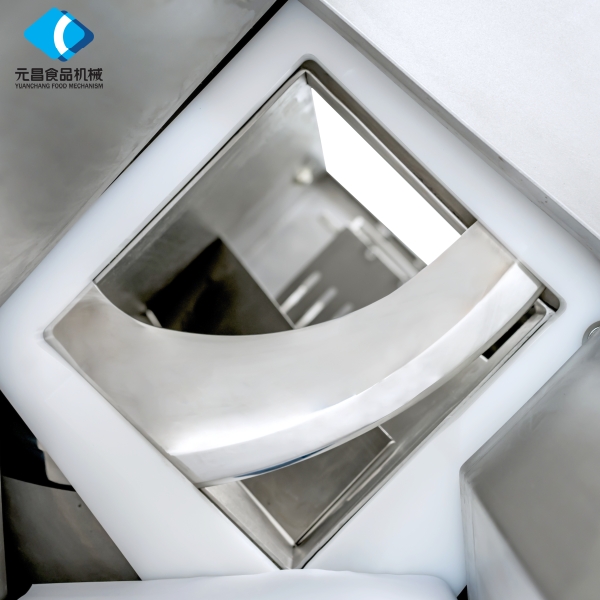

YC MeatMech’s Cutting Rib Machine, built in Shijiazhuang, Hebei Province, China, is designed around two simple truths: keep product steady, and keep operators out of harm’s way. The dynamic feeding system shortens loading time, and that smart‑cut “special claw” (their term, not mine) grips racks so they don’t slide, which—surprisingly—matters more than blade horsepower when you’re chasing uniform rib widths. Many customers say they switched to this unit because QA was tired of uneven cut lines.

Quick spec sheet (real-world use may vary)

| Model | Cutting Rib Machine |

| Origin | Shijiazhuang, Hebei, China |

| Throughput | ≈ 180–350 racks/hour (cut size, species, operator skill) |

| Cut tolerance | ≈ ±2–3 mm across a standard rack |

| Materials | SUS304/316 stainless; food‑grade UHMW contact surfaces |

| Power | ≈ 4–7 kW; 380–480 V, 50/60 Hz, 3PH |

| Pneumatics | 0.6–0.8 MPa clean, dry air |

| Ingress & hygiene | IP65/66 washdown; surfaces Ra ≤ 0.8 μm; passivation per ASTM A967 (typ.) |

| Footprint | ≈ 2.2 m × 1.2 m × 1.8 m |

| Service life | Around 8–12 years with PM; blades are consumables |

Where it fits on the line

Application scenarios: pork spare ribs and St. Louis racks, beef back ribs, and, occasionally, lamb. It slots between primal break-down and trim/QC. Integration is straight: infeed conveyor, guarding with interlocks, outfeed to inspection. Data hooks to MES/SCADA are available if you’re going paperless. And yes, the claw makes a difference when cartilage is slick.

Process flow, testing, and compliance

- Materials: SUS304/316, sealed bearings, food-grade elastomers; tool-less guards where feasible.

- Method: dynamic feeding aligns the rack; smart-cut claw clamps; synchronized blades deliver uniform cuts.

- Testing: FAT with yield and cut-width sampling; SAT on-site; noise and interlock verification; washdown validation.

- Standards: CE (Machinery Directive 2006/42/EC), ISO 14159 hygiene guidance, EN 1672-2, and typical HACCP documentation.

- Service: preventive maintenance intervals at 250/1,000 hours; blade life depends on bone density and sanitation regime.

- Industries: export pork plants, foodservice suppliers, commissaries, and integrated slaughter-to-pack operations.

Vendor comparison (at a glance)

| Vendor | Price band | Lead time | Certifications | Customization | Typical capacity | After‑sales |

|---|---|---|---|---|---|---|

| YC MeatMech (this model) | $$ | 6–10 weeks | CE, ISO 9001 | High (blades, PLC, voltages) | ≈ 180–350 racks/h | Remote + regional partners |

| Global Brand A | $$$ | 12–20 weeks | CE/UL | High | ≈ 200–400 racks/h | Global network |

| Regional OEM | $ | 4–8 weeks | Local marks | Basic | ≈ 120–220 racks/h | Local only |

Customization and options

Blade spacing templates, rib width presets, alternative PLC brands (Siemens/Mitsubishi), voltage packages, extra guarding, and data logging are common requests. Actually, one plant asked for color‑coded tool‑less change parts to reduce training time—simple tweak, big win. If you’re standardizing meat processing equipment across sites, lock the HMI language packs and spare blade SKUs early.

Real-world outcomes

- Hebei pork processor: reported yield uptick ≈ 0.8–1.2% and one fewer operator per shift; cut-width SD tightened by ~25% after commissioning.

- EU export plant: sanitation crew cut changeover by 12 minutes after swapping to tool‑less guards; QA flagged fewer off-spec ribs week over week.

If you’re benchmarking meat processing equipment this quarter, bring your own racks to the FAT. You’ll see immediately whether the claw geometry matches your trim spec. And, I guess this is obvious, but ensure your sanitation chemicals are compatible with seals—longevity in meat processing equipment is usually lost in the wash bay, not the cut box.

Certifications and guidance typically referenced: CE (Machinery), ISO 9001 QMS, ISO 14159 hygiene design, EN 1672‑2, HACCP documentation, and food‑contact compliance for materials. Ask for the FAT protocol, test data, and a parts list that your maintenance team actually recognizes.

Authoritative citations

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025

-

Best Commercial Marinating Machines for Meat Processing | Efficient & ScalableNewsNov.20,2025