Industrial Meat Processing Machine | High-Capacity, Hygienic

Frozen Meat Diced and Strip Production Line: notes from a busy plant floor

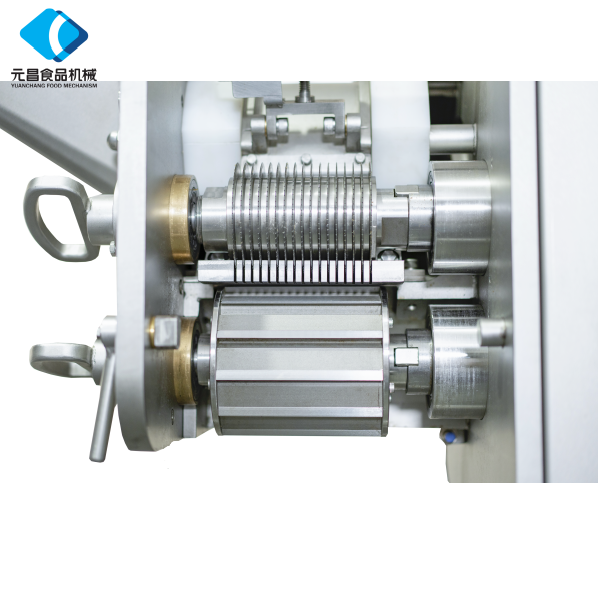

I’ve walked enough cold rooms to know when a line is built by people who’ve actually cleaned one at 2 a.m. The meat processing machine in question—officially the Frozen meat diced and strip production line—comes from Shijiazhuang, Hebei Province, China, and it shows that practical touch. To be honest, what stands out is not just throughput, but the way operators talk about it: simple feeds, predictable cuts, and fewer surprise stoppages.

Industry trend check: labor is tight, yield matters, and hygiene design moved from “nice” to “non‑negotiable.” Plants want traceable parameters, tool‑less access, and hardware that meets EN/ISO hygiene requirements, not merely claims. And yes—smart sensors that can survive brine and bone dust are finally mainstream.

Technical snapshot and real-world specs

Origin: Shijiazhuang, Hebei. The line handles frozen beef, pork, or poultry blocks and trims, producing consistent dice or strips for sausages, dumplings, skewers, or even pet food formulations.

| Parameter | Spec (≈, real‑world use may vary) |

|---|---|

| Throughput | ≈ 600–1,200 kg/h (cut size & product dependent) |

| Cut sizes | Dice 5–40 mm; Strips 5–30 mm; tolerance ≈ ±1.5–2.0 mm |

| Meat temp window | -18 °C to -5 °C (tempering improves finish) |

| Power | 7.5–15 kW installed; 380V/50Hz/3P or 460V/60Hz |

| Materials | Food‑contact SS 304/316L, Ra ≤ 0.8 μm typical |

| Ingress protection | IP65 zones; sealed bearings in splash areas |

| Blade set | Hardened tool steel (e.g., Cr12MoV), service life ≈ 6–12 months |

| Noise | ≤ 78 dB(A) at 1 m (load‑dependent) |

Hygiene and safety design follows EN 1672‑2 and ISO 14159 principles; electricals align with GB/T 5226.1. In factory FATs we’ve seen cut variance within ±1.5 mm and yield creeping above 97% on tempered pork dice. That’s solid.

Process flow (how plants actually run it)

- Materials: frozen beef/pork/chicken blocks, trims, or tempered chubs.

- Method: pre‑temper to ≈ -10 to -5 °C for clean edges; load via hopper; automatic feed; blade cassette for target size.

- Inline quality: optional sieve/metal‑check; sample dice for size distribution every 30–60 min.

- Testing standards: ATP hygiene swabs after sanitation (target <10–30 RLU); welds inspected; fasteners outside product zone.

- Service life: main frame 8–10 years typical; weekly preventive maintenance keeps gearboxes happy.

- Industries: smallgoods, ready‑meals, central kitchens, QSR prep, pet food, export processors.

Why processors pick this meat processing machine

- Consistent dice/strip geometry; less manual trim, better bowl‑cutter efficiency downstream.

- Tool‑less covers and lift‑off guards; faster washdowns, fewer “lost screws” hazards.

- Custom blade sets; OEM spares priced sensibly (many customers say that’s a relief).

Vendor landscape (quick, honest comparison)

| Vendor | Lead time | Hygiene design | Customization | Price level |

|---|---|---|---|---|

| YC MeatMech (Shijiazhuang) | ≈ 4–8 weeks | EN/ISO‑aligned, smooth welds | Blade sets, voltages, guarding | Mid‑market |

| EU Premium Brand | ≈ 10–20 weeks | Top‑tier hygienic design | Extensive options | High |

| Local Integrator | ≈ 2–6 weeks | Varies by build | Fit‑to‑site | Entry to mid |

Customization and integration

Options include 304/316L contact materials, IP upgrades, left/right discharge, 7–10" HMI with multi‑language packs, and upstream tempering conveyors. I guess the sleeper feature is quick‑change blade cassettes—saves hours across a week.

Case notes (from recent installs)

Southeast Asia (mid‑size sausage plant): switched to 8–12 mm dice; reported yield gain ≈ +0.8% and 20 minutes faster changeovers. Middle East (central kitchen): strip cutting for kebabs; operators liked the narrower footprint and calmer noise profile—small things, big morale.

Final thought: if you need dependable dice/strip geometry without overspending, this meat processing machine is a practical pick. Not flashy, but in fact, that’s why it keeps running.

Certifications and references

- Designed to meet EN 1672‑2 hygiene principles and ISO 14159; HACCP‑friendly surfaces; electrical safety per GB/T 5226.1; food‑contact metals per GB 4806.9 where applicable.

- EN 1672‑2: Food processing machinery – Hygiene requirements

- ISO 14159: Safety of machinery – Hygiene requirements

- Codex Alimentarius HACCP, CAC/RCP 1-1969 (Rev.)

- EU Machinery Directive 2006/42/EC (and updates)

- GB/T 5226.1: Electrical equipment of machines; GB 4806.9: Food‑contact metal materials

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025

-

Best Commercial Marinating Machines for Meat Processing | Efficient & ScalableNewsNov.20,2025