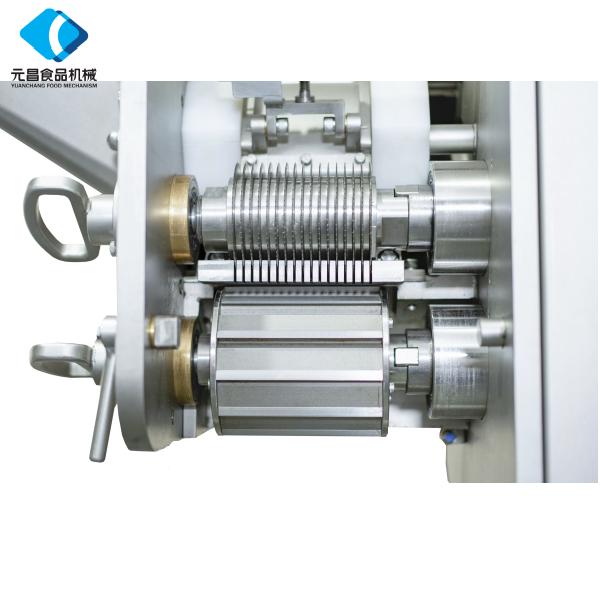

Meat Dicer Machine for Sale – Precise, Hygienic, High-Yield

Insider’s Take: Choosing a Meat Diced Machine That Actually Delivers

If you’ve been hunting for a meat dicer machine for sale, you’ve probably noticed two things: plenty of marketing noise, and surprisingly big differences in real-world performance. I’ve toured plants from Shijiazhuang to Chicago, and—honestly—what matters is reliability, sanitation, and consistent cube accuracy when the line gets busy.

What’s new in meat dicing (and why it matters)

Trends are clear: tighter hygiene design (think no-tool disassembly), variable frequency drives for gentler cuts on semi-frozen blocks, and smarter guarding per CE/EN standards. Processors tell me they want one frame to handle frozen pork (-5 to -2°C), cooked chicken, and even poultry with bone—without changing half the machine. This is where the Meat Diced Machine from Shijiazhuang, Hebei, is getting attention.

Core specs at a glance

| Model (ref.) | Meat Diced Machine |

| Capacity | ≈ 600–1200 kg/h (real-world use may vary by product temp and feed) |

| Cutting range | Dicing 3–30 mm; slicing/strips via tool change |

| Materials | Food-grade SS 304 contact parts; optional 316 for chloride-heavy CIP |

| Motor / Power | 3.0–5.5 kW, 380V 50/60Hz, VFD control |

| Ingress / Safety | IP65 cabinet, interlocked guards, CE-minded design |

| Origin | Shijiazhuang, Hebei Province, China |

| Commercial terms | FOB US$0.5–9,999 / piece; MOQ 100 pcs; supply ≈10,000 pcs/month |

Process flow and test standards

Typical flow: pre-chill blocks (-5 to -2°C) → load → pre-slice → cross-cut → dicing grid → discharge → quick sanitation (tool-free blade cassette). Materials comply with ASTM A240 (SS plate) and food-contact best practices. Factory testing references EN 60204-1 (electrical safety) and internal HACCP checks. Service life? With sensible lubrication and blade rotation schedules, I’ve seen 20,000–30,000 operating hours; blade edges often last 300–600 hours before swap.

Applications and performance notes

- Frozen pork/beef, cooked ham, poultry with bone (selected SKUs), even plant-based blocks.

- Measured data: cube accuracy ±1.5 mm (5–15 mm dice), yield >98%, noise ≤78 dB, energy 2.2–4.5 kWh/h depending on load.

- Industries: central kitchens, ready-meal plants, pet food, quick-serve chains, commissaries.

Many customers say the surprising part is edge integrity on semi-frozen poultry. I’d add: the quick strip-down for washdown is genuinely useful on double-shift schedules.

Vendor comparison (field-notes style)

| Vendor | Strengths | Watch-outs |

|---|---|---|

| YC Meat Mech (Hebei) | Bone-capable option, solid cube accuracy, fast parts lead times | MOQ may be high for micro-processors |

| Generic Brand A | Lower upfront price | Blade steel softer; more frequent regrinds |

| Importer B (EU) | Great documentation; CE certificates on file | Parts cost premium; longer lead times |

Customization and options

- Blade sets: SUS420J2 vs. high-speed steel; optional TiN coating for cooked proteins.

- 316 stainless upgrade for aggressive detergents; drain-friendly frames.

- Dice grids from 3–30 mm; special strip kits for fajita-style cuts.

- Documentation pack: CE conformity, electrical schematics, IQ/OQ support on request.

Mini case studies

Central Kitchen, MENA: Swapped manual cubing for automated dicing; reported 22% labor reduction and steadier 10 mm cubes on cooked chicken. Pet Food Plant, EU: Bone-in poultry SKUs achieved >97% yield with reinforced grid. Butcher Chain, APAC: Weekend spikes handled by running semi-frozen blocks at -3°C—surprisingly clean cuts.

Quality, compliance, and service

Certs typically include ISO 9001 at the factory level and CE conformity for the machine; food safety alignment via HACCP and ISO 22000 in customer plants. Factory FAT can include cube-size verification, guard interlock tests, and insulation checks per EN 60204-1. Warranty often runs 12 months; common spares ship fast from Hebei.

If you’re ready to benchmark a meat dicer machine for sale against your current line, request a cut test with your actual product and target dice sizes. In fact, bring your sanitation lead into the conversation early—makes commissioning smoother.

Authoritative citations

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025

-

Best Commercial Marinating Machines for Meat Processing | Efficient & ScalableNewsNov.20,2025