Meat Dicer Machine for Sale – Precision, Stainless Steel

Looking for a Meat Dicer Machine For Sale? Field Notes From a Buyer’s Desk

If you’ve ever watched a production line wrestle with uneven cubes or slow changeovers, you know why the humble meat dicer is having a bit of a moment. In fact, meat processors from snack sticks to bone-in poultry lines keep asking for one thing: repeatable cuts at industrial speeds without drama. Based in Shijiazhuang, Hebei Province, this “Meat Diced Machine” checks a lot of boxes—frozen blocks, cooked meats, even poultry with bone. And to be honest, the price-to-output ratio is… surprisingly competitive.

Market snapshot

Two trends are driving purchases right now: labor shortages and SKU fragmentation. Many customers say they’re switching from manual dicing or slow multi-knife setups to compact dicers that handle chilled or semi-frozen inputs and keep yields stable. Another trend—cleanability—thanks to auditors pressing EHEDG-style design cues and HACCP-friendly surfaces.

Core specifications (field-proven ranges)

| Model | Meat Diced Machine (industrial) |

| Capacity | ≈ 800–1,500 kg/h (real-world use may vary with cut size/temperature) |

| Cut size range | 3–30 mm cubes; slicing/strip kits available |

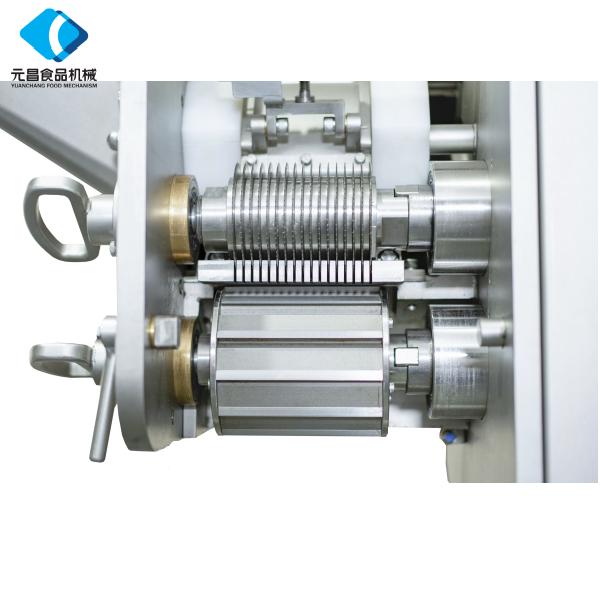

| Material contact parts | SUS304 frame; blades 420J2/440C hardened |

| Input temperature | Cooked/chilled; frozen up to ≈ -5 °C; bone-in poultry compatible |

| Power / Voltage | 4–7.5 kW; 380–415 V, 50/60 Hz, 3-Ph (others on request) |

| Hygiene & IP | IP65 control box; open-frame, tool-less disassembly zones |

| Noise | ≈ 72–78 dB(A) under load |

Where it fits

- Ready meals: diced cooked beef, ham cubes, chicken breast strips.

- Pet food: chilled or semi-frozen blocks for consistent particle size.

- Poultry bone-in trimming: controlled bite-size cuts for stews.

- Snack and deli: uniform cubes for salads, pizza toppings, or soups.

Process flow (typical)

Raw material reception → tempering (if frozen) → pre-trim → feed to Meat Dicer Machine For Sale via safety hopper → dicing/slicing set by spacers → inline metal detection (optional) → weight check → packaging → sanitation (CIP/foam clean, visual ATP test).

QC metrics I’ve seen used: cube accuracy ±1.5 mm on 10 mm setting, yield loss

Vendor comparison (shortlist view)

| Vendor | Price range (FOB) | Lead time | Certifications | Notes |

|---|---|---|---|---|

| YC Meat Mech (Hebei) | ≈ US $0.5–9,999/unit (bulk; MOQ 100) | 20–35 days | CE, ISO 9001; HACCP-ready design | High throughput; bone-in capable |

| EU Brand A | Higher | 30–60 days | CE, EHEDG design principles | Premium finish; pricier spares |

| APAC Brand B | Budget | 15–30 days | Basic CE | Good entry-level; limited bone-in |

Customization and testing

Options include blade sets for 5/8/10/12/20 mm, infeed conveyors, variable frequency drives, and washdown upgrades. Factory FAT usually covers: noise test, cut-size validation on beef/poultry, insulation resistance, and IP splash checks. Compliance typically aligns with CE Machinery Directive 2006/42/EC, EN 60204-1 electrical, and hygienic design good practices (EN 1672-2/EHEDG).

Field story (quick)

A mid-size ready-meal plant in Eastern Europe swapped out two legacy dicers for one unit of this line. They reported +12% throughput and a 15-minute faster sanitation changeover on average. Not exactly a lab study, but the maintenance chief swore the tool-less guards saved his crew’s Fridays.

What I’d watch

- Blade metallurgy vs. your product mix; bone-in needs tougher sets.

- Sanitation access around bearings and corners—walk the machine.

- Spare parts stock and a realistic 12–18 month TCO, not just invoice price.

Supply ability is quoted at 10,000 units/month, which is ambitious, but scale helps when you need fleet rollouts. If you’re shopping for a Meat Dicer Machine For Sale with balanced performance, this one belongs on the shortlist.

References

- EU Machinery Directive 2006/42/EC.

- EN 1672-2: Food processing machinery – Basic concepts – Hygienic requirements.

- EN 60204-1: Safety of machinery – Electrical equipment of machines.

- EHEDG Guidelines for hygienic design (overview papers).

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025

-

Best Commercial Marinating Machines for Meat Processing | Efficient & ScalableNewsNov.20,2025