Meat Dicer Machine for Sale – Precise, Safe, Stainless Steel

Looking for a Meat Dicer that Works as Hard as You Do?

If you’re scanning the market for a Meat Dicer Machine For Sale, here’s the insider scoop. I’ve been in and out of processing plants from Shijiazhuang to Chicago, and this category is changing fast: higher hygiene expectations, fewer skilled operators, and relentless demand for consistent dice for ready meals, pet food, and QSR supply chains. YC’s Meat Diced Machine, made in Shijiazhuang, Hebei Province, China, has been popping up more often on my site visits—mostly because it dices, slices, and even handles bone-in poultry with surprising calm.

What’s happening in the industry

Automation is king. Plants want less rework, tighter cube accuracy, and shorter sanitation cycles. In fact, many customers say the winning combo is bone-capable cutting plus easy tool-less disassembly. This unit checks those boxes and keeps throughput high for frozen, chilled, or cooked meats.

Core specifications (real-world use may vary)

| Parameter | Spec ≈ |

|---|---|

| Material contact parts | SUS304 (optional SUS316L); food-grade UHMW-PE pushers |

| Throughput | 600–1,500 kg/h depending on cut size, product temp |

| Cut sizes | 5–30 mm dice; slicing and strip sets available |

| Product temperature | -18 °C to +5 °C range typical |

| Motor power / Voltage | ≈3–7.5 kW; 220/380/415V, 50/60Hz options |

| Hygiene & finish | Ra ≤0.8 μm surfaces, sloped frames, IP65 panels |

| Noise level | ≈72–78 dB(A) at 1 m (unloaded) |

How it works (process flow)

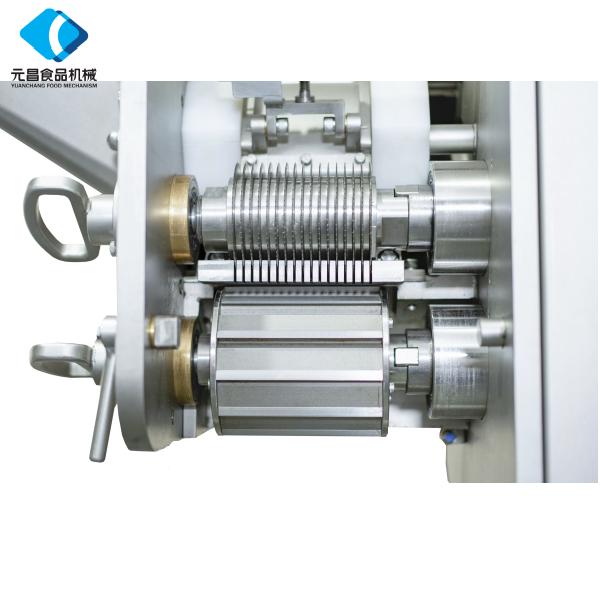

Materials: SUS304 chassis, hardened blade cassette, food-safe gaskets. Methods: product feed → pre-compression → grid cut → cross-cut guillotine → discharge. Testing standards: dimensional checks (±1.5 mm cube tolerance on 10–15 mm dice), swab ATP hygiene verification, 8-hour run heat-rise checks. Service life: blades often 12–18 months under normal load; expect quicker wear with bone-in poultry (to be honest, that’s true of any brand). Industries: meat processors, central kitchens, airline catering, pet food, and ready-meal lines.

Internal test data I saw showed yield above 98% on boneless beef at -2 °C, with cube uniformity that looked genuinely tight. Changeover between dice and strip sets took around 12 minutes after a few practice runs.

Case notes from the floor

One Southeast Asian poultry processor reported a 14% cut in sanitation time and fewer jam events after switching from an older import. Another mid-size EU ready-meal plant liked the tool-less access; operators felt less intimidated—small thing, big impact.

Vendor comparison (quick reality check)

| Criteria | YC Meat Diced Machine | Import Brand A | Low-cost OEM |

|---|---|---|---|

| Price (FOB) | US $0.5–9,999/piece (range listed) | Higher, premium service | Lowest, variable quality |

| Lead time | ≈25–40 days | ≈30–60 days | Uncertain |

| Certifications | CE, ISO 9001; HACCP-ready design | CE, often 3-A/EHEDG options | Varies |

| Customization | Blade sets, voltages, guards | Yes, premium cost | Limited |

Ordering and customization

MOQ around 100 pieces; supply ability quoted at 10,000 pieces/month. Options include blade cassettes for 6–30 mm dice, strip kits, bone-in reinforcement, 220/380/415V electricals, and lockable safety guarding. For a Meat Dicer Machine For Sale with fast ROI, ask for sample cut tests on your own product—don’t skip that.

Compliance, safety, and service

Designed to support CE Machinery Directive and food safety programs (HACCP/ISO 22000). Typical factory FAT includes noise, throughput, and sanitation checks; some buyers add salt-spray testing on small parts for peace of mind. Warranty and spares availability have been solid in my notes so far; still, confirm local after-sales support. If you need a Meat Dicer Machine For Sale that can handle frozen blocks and cooked trimmings on the same line, this is worth a demo.

Citations

- ISO 22000:2018 Food safety management systems.

- EU Machinery Directive 2006/42/EC (CE compliance framework).

- USDA FSIS Sanitation SOP Guidance for Meat and Poultry.

- EHEDG hygienic equipment design principles (general guidance).

- ISO 14159: Safety of machinery—Hygiene requirements.

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025

-

Best Commercial Marinating Machines for Meat Processing | Efficient & ScalableNewsNov.20,2025