Frozen Meat Slicer: Cut Ultra-Thin, Fast & Safe?

frozen meat slicer,meat slicer for frozen meat,frozen food slicer,commercial frozen meat slicer,frozen meat slicer commercial is a key solution in the Machinery and equipment industry, specifically within Food Machinery and Meat processing equipment. This article explores how Hebei Yuanchang Food Mechanism & Technology Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- frozen meat slicer,meat slicer for frozen meat,frozen food slicer,commercial frozen meat slicer,frozen meat slicer commercial Overview

- Benefits & Use Cases of frozen meat slicer,meat slicer for frozen meat,frozen food slicer,commercial frozen meat slicer,frozen meat slicer commercial in Meat processing equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Machinery and equipment

- Conclusion on frozen meat slicer,meat slicer for frozen meat,frozen food slicer,commercial frozen meat slicer,frozen meat slicer commercial from Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

frozen meat slicer,meat slicer for frozen meat,frozen food slicer,commercial frozen meat slicer,frozen meat slicer commercial Overview

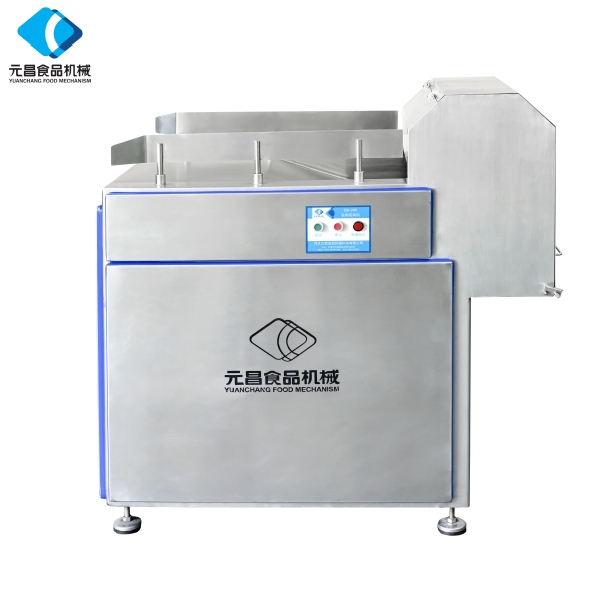

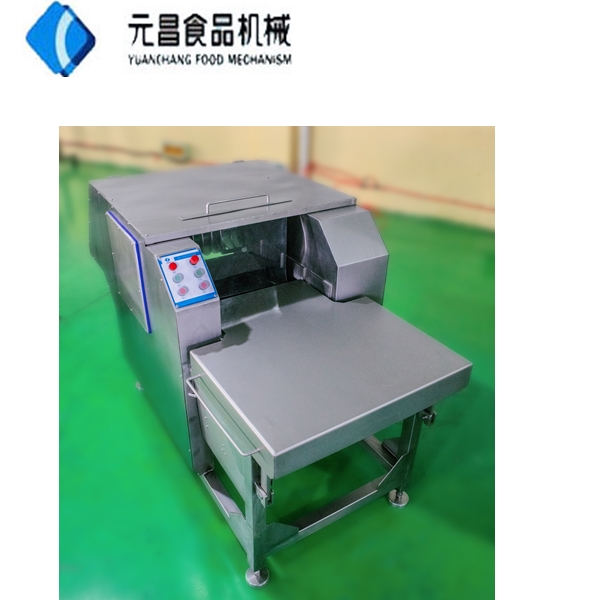

A frozen meat slicer is engineered to portion and pre-cut blocks, slabs, or logs of sub-zero proteins with speed, accuracy, and hygienic reliability. In the Machinery and equipment category—specifically Food Machinery and Meat processing equipment—this machine safeguards product integrity while delivering uniform slices or chunks ready for grinding, marination, mixing, or packaging. As a meat slicer for frozen meat, it minimizes thaw loss and preserves texture and yield, making it indispensable across abattoirs, central kitchens, further-processing plants, and distribution centers.

Hebei Yuanchang Food Mechanism & Technology Co., Ltd. designs its commercial frozen meat slicer to meet industrial demands: robust stainless-steel construction, food-grade components, guarded cutting zones, and user-friendly controls for repeatable results. Operators can set slice thickness, throughput, and feed patterns to match recipes or downstream equipment capacity. The frozen food slicer configuration supports clean-in-place or fast disassembly for sanitation, while interlocks and emergency stops protect crews during washdown and operation. With proven build quality, application engineering, and dependable after-sales support, Hebei Yuanchang provides a frozen meat slicer commercial buyers can count on for consistent, high-volume performance.

Benefits & Use Cases of frozen meat slicer,meat slicer for frozen meat,frozen food slicer,commercial frozen meat slicer,frozen meat slicer commercial in Meat processing equipment

From quick-service supply chains to prepared-meal factories, a commercial frozen meat slicer enhances line efficiency and product consistency. Typical use cases include pre-slicing frozen beef, pork, mutton, poultry, and fish blocks prior to grinding; cutting uniform chunks for stews and ready meals; and portioning controlled slices for hotpot, bacon-style products, or jerky. Precision slicing at sub-zero temperatures stabilizes fibers and reduces smear, supporting higher yields and better bite.

Key advantages of Hebei Yuanchang’s meat slicer for frozen meat include repeatable thickness control, smooth product transfer, and easy sanitation. The machine’s heavy-duty frame and drive system handle dense frozen materials while maintaining a clean cut profile. Safety guards, non-slip operator areas, and intuitive HMI/PLC controls streamline setup and changeovers. Integration options—such as conveyors to grinders, mixers, or tumblers—help processors build continuous lines that cut labor, shorten cycle times, and improve traceability. Backed by Hebei Yuanchang’s application expertise in Meat processing equipment, the frozen food slicer can be configured to your product sizes, target weights, and hygiene protocols.

Cost, Maintenance & User Experience

Total cost of ownership for a frozen meat slicer depends on throughput needs, shift patterns, cleaning regimes, and spare parts planning. Hebei Yuanchang focuses on durable components and simplified sanitation to reduce downtime and extend service intervals. Tool-less access to product-contact areas, sloped surfaces for drainage, and corrosion-resistant materials lower cleaning time and chemical use. Consumables like blades and seals are standardized where possible to control inventory cost and speed replacement.

Processors report that a well-specified frozen meat slicer commercial unit delivers fast ROI by stabilizing yields, reducing manual cutting labor, and improving downstream grinder or mixer efficiency. Operators appreciate clear HMI prompts, recipe recall, and safety interlocks that support safe, repeatable operation even in cold-room environments. Maintenance teams benefit from straightforward diagnostics and responsive parts/service from Hebei Yuanchang Food Mechanism & Technology Co., Ltd. For B2B decision makers, the result is predictable uptime, consistent product quality, and a payback profile aligned with high-volume Food Machinery operations.

Sustainability & Market Trends in Machinery and equipment

Food processors face growing pressure to reduce waste, document hygiene, and minimize energy use—while meeting stringent regulatory frameworks like HACCP and global food-safety standards. A modern frozen meat slicer supports these goals by portioning accurately (cutting giveaway and rework), preserving moisture, and enabling cold-chain integrity through minimal thaw time. Hygienic design and fast cleaning reduce water and chemical consumption, while robust materials extend machine life and recyclability.

Market trends in Meat processing equipment include automation, data-driven optimization, and line integration. Processors increasingly seek frozen food slicers that interface with upstream block handling and downstream grinding, weighing, and packaging—capturing KPIs such as throughput, slice thickness conformity, and downtime causes. Hebei Yuanchang Food Mechanism & Technology Co., Ltd. embraces these trends with configurable controls, integration-ready architecture, and continuous design improvements aimed at safer operation, easier sanitation, and lower lifecycle impact. This forward-thinking approach helps clients scale capacity while supporting sustainability commitments and compliance objectives.

Conclusion on frozen meat slicer,meat slicer for frozen meat,frozen food slicer,commercial frozen meat slicer,frozen meat slicer commercial from Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

A purpose-built frozen meat slicer brings accuracy, hygiene, and throughput to protein processing lines. Whether you need a meat slicer for frozen meat, a frozen food slicer for chunking, or a high-throughput commercial frozen meat slicer integrated into a continuous line, Hebei Yuanchang Food Mechanism & Technology Co., Ltd. delivers durable, serviceable solutions that protect yield and product quality. For specifications, configurations, and quotations, our team is ready to help you engineer the right fit.

Contact us: email: ycmeatmech@gmail.com

Visit our website: https://www.ycmeatmech.com

Product details: Frozen Meat Slicing & Meat Chunks Machine

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025

-

Best Commercial Marinating Machines for Meat Processing | Efficient & ScalableNewsNov.20,2025