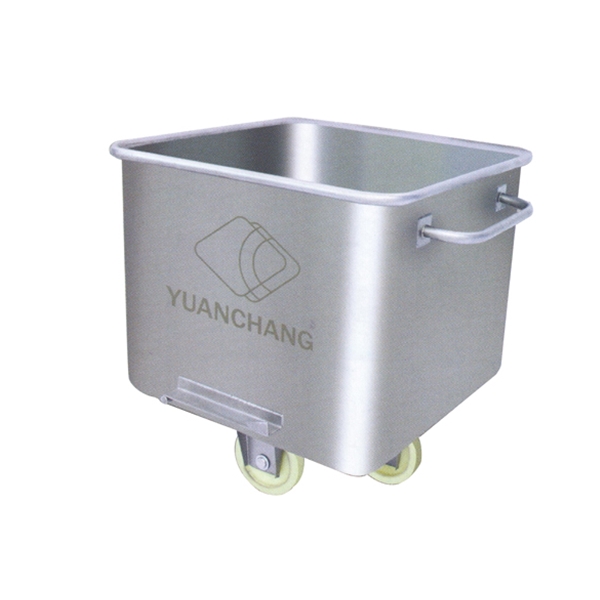

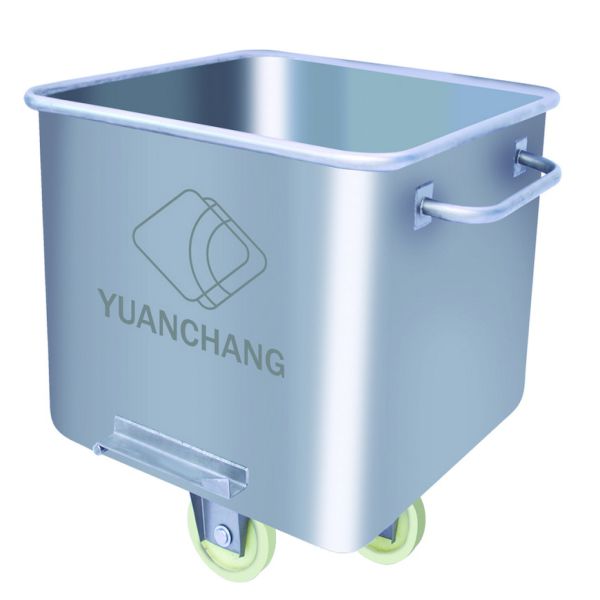

Hopper Trolley: Heavy-Duty Tilting Design for Faster Work?

Inside the RC-200: A Practical Look at a Modern hopper trolley

Walk into any meat or ready-meal plant and you’ll see it right away: the workhorse on wheels. To be honest, the unsung hero is the hopper trolley, and the HOPPER TROLLEY RC-200 from Shijiazhuang, Hebei (yes, the same city that’s become a quiet powerhouse for food-processing kit) is one I’ve seen in action more than a few times.

Industry trends (and why they matter)

- Hygienic design first: radiused corners, continuous welds, and low Ra finishes are becoming baseline, not “nice-to-have.”

- Automation-ready: more plants want hopper trolley units compatible with dumpers, lifts, and AGVs.

- Durability over disposability: rising steel costs push buyers toward long service-life gear.

- Traceability: color coding, laser-etched IDs, and optional RFID tags are popping up everywhere.

RC-200 quick specs

Made of SU304 (aka 304) stainless steel with surface treatment, the RC-200 is designed for easy cleaning, economic operation, and daily abuse. Many customers say it “just rolls smoother,” which, surprisingly, usually comes down to bearing choice and weld quality.

| Model | HOPPER TROLLEY RC-200 | Origin | Shijiazhuang, Hebei, China |

| Volume | ≈200 L (DIN 9797 compatible) | Material | SU304 (ASTM A240 304) stainless steel |

| Wall thickness | around 2.0–2.5 mm (real-world use may vary) | Finish | Pickled & passivated; Ra ≤ 0.8 μm typical |

| Welds | TIG, continuous, radiused corners | Casters | PU-tired, SS housings, sealed bearings |

| Load rating | Dynamic ≈ 200–250 kg; Static up to 300 kg | Service life | 5–10 years with routine maintenance |

How it’s built (the short version)

Materials are certified 304 sheets and tube stock. Panels are laser-cut, edges deburred; then TIG-welded with continuous seams. After weld dressing, the body is pickled and passivated. Optional electropolishing is available for extra sheen and lower micro-roughness. Each hopper trolley is dimension-checked against DIN 9797 gauges; welds may get random dye-penetrant tests (ISO 3452) and salt-spray sampling per ISO 9227. Load-cycle tests (e.g., 1,000 cycles at 200 kg) are used for fatigue screening.

Where it shines

- Meat and poultry batching, trim handling, and cooker loading.

- Seafood brining rooms; bakery and confectionery (wet mixes).

- Pet food and ingredient staging; even light chemical solids where 304 is suitable.

Feedback I’ve heard: “less slosh,” “easy to tip into the dumper,” and, yes, “welds don’t snag.” Small details, big impact on shift morale.

Vendor snapshot: how RC-200 stacks up

| Feature | RC-200 | Generic EU Bin | Budget Import |

|---|---|---|---|

| Steel grade | 304 with certs | 304/316 options | 304 (unspecified) |

| Finish | Pickled/passivated | Electropolished (option) | Brushed only |

| Load-cycle testing | Yes (≈1,000 cycles) | Varies by model | Rare |

| Certifications | ISO 9001, CE, 3.1 material cert | ISO 9001 | None/limited |

| Price range | Mid | High | Low |

Customization and options

Need color-coded handles, laser-etched IDs, a drain bung, or anti-static wheels? The factory can tweak the hopper trolley geometry, wall thickness, and caster spec. For aggressive cleaners, consider 316 steel (for some parts) and high-temp grease seals.

Field note: brief case

A mid-size sausage plant in North China swapped mixed-age bins for RC-200 units. Result after 8 weeks: 12% faster batch changeovers, fewer lift-dumper misalignments, and—this was unexpected—noise reduction on night shift thanks to better caster bearings. Not magic, just decent engineering.

Standards and references

- ASTM A240/A240M – Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip.

- DIN 9797 – Meat trolley (200 L) dimensional standard.

- EN 1672-2 – Food processing machinery – Basic concepts – Hygiene requirements.

- ISO 9227 – Corrosion tests in artificial atmospheres – Salt spray tests.

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025

-

Best Commercial Marinating Machines for Meat Processing | Efficient & ScalableNewsNov.20,2025