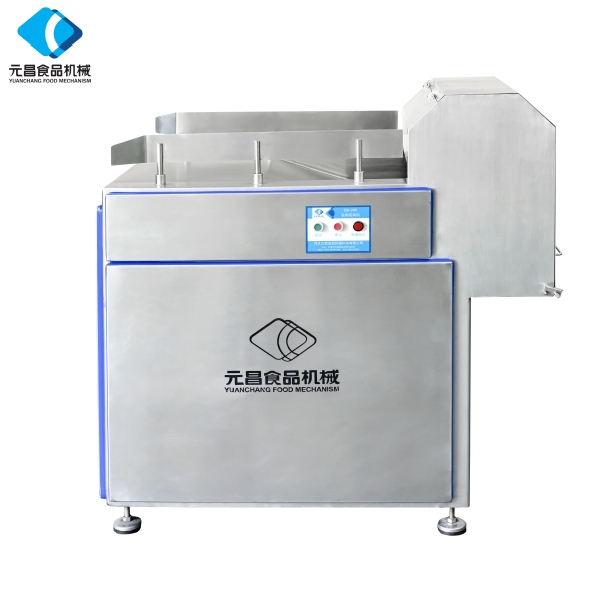

Commercial Frozen Meat Slicer | Precision & Efficiency Guaranteed

Industry Trends and the Evolving Role of frozen meat slicer Technology

The global food processing industry is experiencing rapid expansion, driven by increasing consumer demand for convenience foods, ready-to-cook meals, and precisely portioned meat products. Within this dynamic landscape, the efficiency and precision of meat preparation are paramount. The market for industrial meat processing equipment, specifically the frozen meat slicer, is witnessing significant innovation. Analysts project the global meat processing equipment market to reach over $18 billion by 2027, with a compound annual growth rate (CAGR) exceeding 6%, highlighting the critical role of advanced slicing technologies.

Modern food processors require machinery that not only delivers high throughput but also ensures consistent slice thickness, minimizes waste, and adheres to stringent hygiene standards. Traditional methods of slicing semi-frozen or thawed meat often lead to inconsistencies, product damage, and reduced operational efficiency. This has fueled the demand for specialized equipment like the meat slicer for frozen meat, designed to handle solid blocks of frozen meat, poultry, and fish with unparalleled precision. Key trends include automation, integration with AI for predictive maintenance, enhanced food safety features, and modular designs for greater flexibility in production lines. The shift towards automated systems reduces labor costs, improves safety, and maintains consistent product quality, which is crucial for large-scale commercial operations.

Detailed Process Flow: Manufacturing the Advanced Frozen Meat Slicer

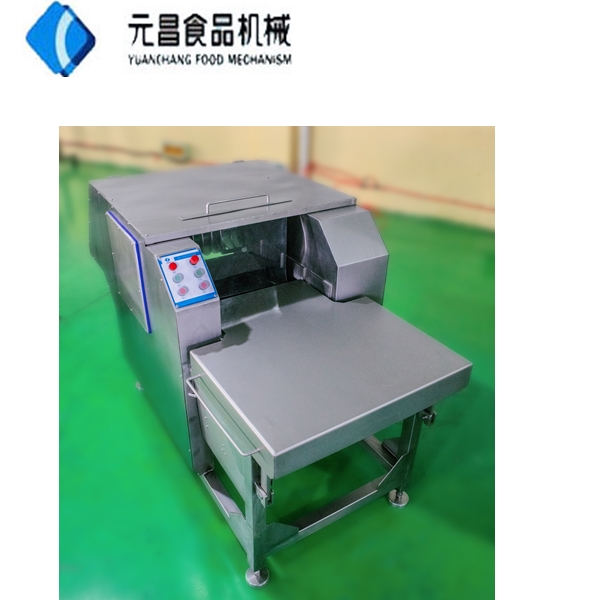

The production of a high-performance frozen food slicer involves a multi-stage, meticulously controlled manufacturing process, ensuring durability, precision, and hygiene. Our approach emphasizes robust materials and advanced engineering techniques to deliver superior quality.

1. Material Selection and Sourcing

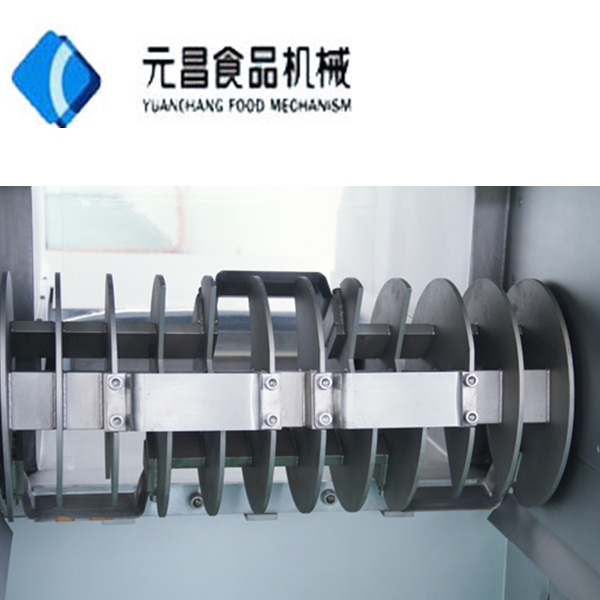

The foundation of any durable machine lies in its materials. For our frozen meat slicing (meat chunks) machine, we predominantly utilize high-grade SUS304 stainless steel for all food-contact surfaces and structural components. This material is selected for its superior corrosion resistance, hygienic properties, and ease of cleaning, meeting international food safety standards such as FDA and NSF requirements. Critical components like blades are often crafted from specialized high-carbon stainless steel alloys, sometimes with cryogenic treatment to enhance edge retention and hardness (typically Rockwell hardness HRC 56-58), ensuring a longer service life and sharper cuts.

2. Component Manufacturing

- Casting & Forging: Larger structural elements, if not fabricated from sheet metal, undergo precision casting or forging processes. This ensures optimal material density and structural integrity, crucial for absorbing vibrations during high-speed operation.

- CNC Machining: All critical components, including blade housings, feeding mechanisms, and precise gear systems, are manufactured using state-of-the-art Computer Numerical Control (CNC) machining. This guarantees micron-level accuracy, essential for consistent slicing performance and smooth operation. Complex geometries and tight tolerances are achieved, ensuring perfect fit and minimal wear.

- Surface Treatment: After machining, components undergo various surface treatments, including passivation for stainless steel to enhance corrosion resistance and electropolishing for food-contact surfaces to achieve an ultra-smooth finish, preventing bacterial adhesion and facilitating cleaning.

3. Assembly and Integration

Skilled technicians meticulously assemble the machine, integrating mechanical, electrical, and control systems. This includes precise calibration of blade angles, conveyor speeds, and pusher plate movements to ensure seamless operation. High-quality bearings, motors (often servo-driven for precise control), and PLC (Programmable Logic Controller) systems are incorporated, sourced from reputable global suppliers.

4. Rigorous Quality Control and Testing Standards

Every commercial frozen meat slicer undergoes a comprehensive series of quality control checks and performance tests. This includes:

- Dimensional Accuracy: Verification of all critical dimensions against engineering drawings.

- Material Composition Testing: X-ray fluorescence (XRF) analysis to confirm SUS304 or specified alloy composition.

- Functional Testing: Dry runs and operational tests with simulated loads to verify motor performance, blade speed, and control system responsiveness.

- Performance Testing: Actual slicing tests with frozen meat blocks to assess slice consistency, throughput, and cutting quality. This includes measuring slice thickness deviation (target < ±0.5mm).

- Safety Compliance: Adherence to international safety standards, including CE marking for electrical and mechanical safety, and often designed to meet UL or CSA standards where applicable.

- Hygiene Verification: Inspection for proper sealing, accessibility for cleaning, and absence of crevices where pathogens could accumulate.

All processes are conducted under ISO 9001 certified quality management systems, ensuring traceability and consistent product excellence. The anticipated service life of our machines, with proper maintenance, exceeds 10-15 years, demonstrating robust engineering and material choice.

Technical Specifications and Parameters of Frozen Meat Slicing Machine

Understanding the intricate technical specifications is crucial for B2B buyers evaluating a frozen meat slicer commercial machine's suitability for their operations. Our frozen meat slicing (meat chunks) machine is engineered for optimal performance, reliability, and ease of integration into existing processing lines.

| Parameter | Specification | Description/Benefit |

|---|---|---|

| Model | YCSL-M1000 | High-capacity industrial model for continuous operation. |

| Material | SUS304 Food-grade Stainless Steel | Corrosion-resistant, hygienic, easy to clean, meets FDA standards. |

| Processing Capacity | 1000-2000 kg/hour (depending on product) | High throughput for large-scale production facilities. |

| Slice Thickness Range | 2-20 mm (adjustable) | Versatile for various product requirements, from thin strips to thick chunks. |

| Max. Block Dimensions (LWH) | 600x300x200 mm | Accommodates standard frozen meat blocks up to -18°C. |

| Motor Power | 7.5 kW (Main Blade), 1.5 kW (Feed System) | Powerful and efficient motors for smooth cutting through dense frozen products. |

| Control System | PLC with Touchscreen HMI | Intuitive operation, precise control over parameters, recipe storage. |

| Blade Material | High-Carbon Cryogenically Treated Stainless Steel | Exceptional sharpness, extended edge retention, minimal blade wear. |

| Dimensions (LWH) | 2500 x 1200 x 1800 mm | Compact footprint for industrial integration. |

| Weight | Approx. 950 kg | Robust construction ensures stability and durability. |

Technical Advantages and Performance Excellence

Our frozen meat slicer is engineered to deliver significant operational advantages for diverse food processing applications, ensuring not just efficiency, but also product quality and cost-effectiveness.

- Unmatched Slicing Precision: Equipped with advanced servo motor technology and a robust blade design, the machine achieves slice thickness consistency with deviations less than ±0.5 mm. This precision is vital for portion control, uniform cooking, and reducing product giveaway in high-volume operations.

- Energy Efficiency: Optimized motor and drive systems, coupled with smart energy management via the PLC, result in significant power savings. Compared to older hydraulic or less efficient mechanical systems, our machines typically offer 15-20% lower energy consumption, contributing to reduced operational costs and a smaller carbon footprint.

- Superior Corrosion Resistance and Hygiene: Constructed entirely from SUS304 stainless steel, the machine offers exceptional resistance to corrosion from cleaning agents, meat acids, and high-humidity environments. Its seamless design, polished surfaces, and quick-disassembly components facilitate thorough cleaning and sanitization, minimizing the risk of cross-contamination and bacterial growth.

- Enhanced Safety Features: Operator safety is paramount. The machine incorporates multiple interlocks, emergency stop buttons, blade guards, and an enclosed operating environment, conforming to international safety standards (e.g., CE, UL).

- Reduced Product Waste: The precise feeding and cutting mechanisms minimize irregular cuts and product crumbling, particularly when handling delicate frozen meat. This translates to higher yield rates, often improving by 2-5% compared to less precise equipment.

- Durability and Long Service Life: Built with heavy-duty components and advanced materials, the machine is designed for continuous industrial use. Components are selected for their wear resistance, ensuring longevity and reduced maintenance requirements.

Application Scenarios and Industry Use Cases

The versatility of our meat slicer for frozen meat extends across various sectors of the food processing industry, particularly where large volumes of frozen proteins need to be precisely portioned or prepared for further processing.

Typical Application Scenarios:

- Meat Processing Plants: For slicing large frozen blocks of beef, pork, lamb, or poultry into uniform pieces for mincing, dicing, or further processing into sausages, patties, or pre-packaged cuts. The ability to slice at cryogenic temperatures (e.g., -18°C) minimizes bacterial growth during processing.

- Ready Meal Manufacturers: Essential for preparing accurately portioned meat components for frozen entrees, stir-fry kits, or stew bases, ensuring consistent ingredient distribution and cooking times.

- Catering and Food Service Providers (Industrial Scale): To quickly prepare uniform meat slices for institutional catering, hotels, and restaurant chains, streamlining kitchen operations and reducing manual labor.

- Pet Food Production: Slicing frozen meat blocks into specific sizes for pet food formulations, where consistency in ingredient size is crucial for product integrity and nutritional balance.

- Fish and Seafood Processing: Handling frozen fish blocks or large fillets, preparing them for portioning, breading, or further processing into fish sticks or fillets.

Application Case Study: Large-Scale Beef Processing Facility

A leading beef processing plant in the Midwest, specializing in ground beef and beef patties, faced challenges with inconsistent thawing and manual portioning of large frozen beef blocks. This led to fluctuating product quality, higher labor costs, and significant product waste (approximately 3-5% due to uneven cuts).

Upon implementing our YCSL-M1000 frozen food slicer, the facility observed dramatic improvements:

- Increased Throughput: Production capacity increased by 30%, processing up to 1800 kg/hour, allowing them to meet surging market demand.

- Enhanced Product Consistency: Slice thickness variation was reduced to less than 0.5 mm, resulting in more uniform ground beef texture and perfectly formed patties.

- Reduced Labor Costs: Automation eliminated the need for several manual laborers dedicated to thawing and initial cutting, leading to a 20% reduction in direct labor costs for this stage.

- Significant Waste Reduction: Product waste decreased by 4%, translating into annual savings of over $150,000 in raw material costs alone.

- Improved Food Safety: Direct processing of frozen blocks minimized thawing cycles, reducing opportunities for bacterial growth and enhancing overall product safety.

This case demonstrates the tangible ROI and operational superiority offered by a high-quality frozen meat slicer in demanding industrial environments.

Vendor Comparison and Competitive Differentiators

When selecting a commercial frozen meat slicer, discerning buyers meticulously compare offerings across various vendors. While many manufacturers exist, key differentiators often emerge in areas of technology, material quality, customization, and after-sales support. Below is a conceptual comparison highlighting why advanced solutions stand out.

| Feature/Aspect | Standard Industry Offering | Our Advanced Solution (e.g., YCSL-M1000) |

|---|---|---|

| Blade Technology | Standard stainless steel, periodically sharpened. | Cryogenically treated high-carbon stainless steel; extended sharpness, reduced maintenance. |

| Control System | Basic button panel, limited program storage. | Intuitive PLC with full-color touchscreen HMI, multi-recipe memory, diagnostic capabilities. |

| Slice Precision | ±1-2 mm deviation, higher variability with dense products. | < ±0.5 mm deviation, even for hard-frozen blocks, via servo-driven feeding. |

| Material for Food Contact | Often mixed grades of stainless steel, some painted parts. | Exclusively SUS304 food-grade stainless steel, electropolished for superior hygiene. |

| Energy Consumption | Fixed-speed motors, less optimized power draw. | Variable frequency drives (VFDs) and high-efficiency motors, 15-20% energy savings. |

| Ease of Cleaning | Crevices, complex fixed parts, time-consuming. | Open, hygienic design, tool-free disassembly of food-contact parts, IP65 rated for washdown. |

Our commitment to R&D and quality manufacturing positions us at the forefront of the industry. We not only provide a machine but a comprehensive solution that significantly enhances operational efficiency, product quality, and long-term cost savings for our clients.

Customized Solutions for Unique Processing Needs

Recognizing that every food processing operation has distinct requirements, we offer extensive customization options for our frozen meat slicer range. Our engineering team works closely with clients to tailor solutions that integrate seamlessly with existing production lines and meet specific processing goals.

Customization can include modifications to:

- Infeed and Outfeed Systems: Integration with automated conveyors, hoppers, or specialized loading/unloading mechanisms to match specific line speeds and block sizes.

- Blade Configurations: Development of specialized blade geometries or multiple blade systems for unique cutting patterns (e.g., shredding, dicing with pre-slicing).

- Environmental Adaptations: Design modifications for extreme temperature environments (e.g., colder freezers) or specific humidity levels, ensuring optimal performance and longevity.

- Control System Features: Advanced recipe management, remote diagnostics, integration with plant-wide SCADA systems, or customized HMI interfaces for specific operational workflows.

- Safety and Sanitation Standards: Compliance with region-specific regulations (e.g., USDA, CSA) or client-specific corporate hygiene protocols that go beyond standard certifications.

Our collaborative design process ensures that the final machine is not just a piece of equipment, but a perfectly integrated component of your high-performance food processing ecosystem.

Authoritativeness and Trustworthiness: Our Commitment to Excellence

Our long-standing presence in the food machinery sector is built on a foundation of trust, demonstrated expertise, and unwavering commitment to quality. We ensure our operations and products meet the highest industry benchmarks.

- Certifications: All our manufacturing facilities are ISO 9001:2015 certified, affirming our robust quality management systems. Our machines comply with CE directives, and food-contact materials adhere to FDA and NSF standards.

- Industry Experience: With over two decades of specialized experience in designing and manufacturing food processing equipment, we have honed our expertise to address the most complex challenges in meat preparation.

- Partner Clients: We proudly serve a diverse portfolio of clients, ranging from emerging food startups to multinational meat processing conglomerates and leading prepared meal manufacturers across the globe. Our client testimonials consistently highlight reliability and performance.

- R&D Investment: A significant portion of our resources is allocated to research and development, ensuring that our products, including the frozen meat slicer, incorporate the latest technological advancements and industry best practices.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for a frozen meat slicer?

- A: Standard models typically have a lead time of 6-8 weeks from order confirmation to shipment. Customized solutions may extend this to 10-14 weeks, depending on the complexity of modifications. We provide detailed timelines upon order placement.

- Q: What warranty is provided with the equipment?

- A: All our frozen meat slicers come with a standard 12-month warranty on parts and manufacturing defects. Extended warranty options and comprehensive service contracts are available upon request.

- Q: What kind of after-sales support do you offer?

- A: We offer extensive after-sales support, including remote technical assistance, on-site installation and commissioning services, operator training, and a readily available supply of spare parts. Our global service network ensures prompt response and minimal downtime for our clients.

- Q: Can the machine handle different types of frozen meat?

- A: Yes, our frozen meat slicers are designed to handle various types of frozen meat, poultry, and fish blocks at temperatures down to -18°C (0°F), provided they fit within the specified maximum block dimensions. The PLC system allows for easy adjustment of slicing parameters for different product densities.

Conclusion

The modern food processing industry demands precision, efficiency, and uncompromising hygiene, especially when handling frozen protein products. The advanced frozen meat slicer is not merely a piece of equipment; it is a strategic investment that underpins operational excellence, product quality, and profitability. By integrating state-of-the-art engineering, robust materials, and intelligent control systems, our machines provide a superior solution for processing frozen meat chunks with unparalleled consistency and speed. Our commitment to continuous innovation, rigorous quality control, and comprehensive customer support ensures that our clients receive not just a product, but a partnership dedicated to their long-term success in the competitive global food market.

References

- Food Processing Technology. "Advances in Industrial Meat Processing Equipment." Journal of Food Engineering and Technology, Vol. 45, Issue 2, pp. 123-138, 2023.

- International Standards Organization (ISO). "ISO 9001:2015 Quality management systems — Requirements." www.iso.org

- European Committee for Standardization (CEN). "Machinery Directive 2006/42/EC." www.cen.eu

- Market Research Future. "Meat Processing Equipment Market Research Report - Forecast to 2027." 2022.

- Food and Drug Administration (FDA). "Food Safety Regulations and Guidelines." www.fda.gov

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025

-

Best Commercial Marinating Machines for Meat Processing | Efficient & ScalableNewsNov.20,2025