Buffalo Chopper Bowl: Efficient Food Prep for Commercial Use

Introduction to Advanced Bowl Chopper Technology

In the demanding landscape of food processing, precision, efficiency, and hygiene are paramount. The buffalo chopper bowl stands as a cornerstone technology, enabling the creation of finely emulsified products, from sausages and pâtés to processed cheese and vegetable purees. Far beyond a simple mixer, modern industrial bowl cutters represent sophisticated engineering, capable of achieving ultra-fine particle size reduction while maintaining product integrity and temperature control. This equipment is critical for achieving desired textures, improving product yield, and ensuring consistent quality across various food applications. Its evolution has been driven by the need for enhanced performance, energy efficiency, and compliance with stringent food safety standards, making it an indispensable asset in the commercial and industrial food sector.

The scope of application for these powerful machines extends across numerous processing tasks. Whether it's the high-speed chopping required for meat products, the delicate emulsification for vegetable-based foods handled by a vegetable slicer with bowl functionality, or the specialized requirements of a vacuum bowl cutter to prevent oxidation and improve shelf life, the underlying technology focuses on maximizing product quality and operational throughput. This article will delve into the intricacies of this vital equipment, exploring its manufacturing, technical advantages, and diverse applications in modern food production.

Manufacturing Process of the Industrial Bowl Cutter

The production of a high-performance buffalo chopper bowl involves a meticulous series of engineering and manufacturing steps designed to ensure durability, precision, and hygienic operation. The core components, particularly the bowl itself and the cutter head assembly, demand superior material quality and advanced fabrication techniques.

Material Selection and Preparation:

- Stainless Steel (AISI 304/316L): The primary material for the bowl, cutter housing, and exposed components is food-grade stainless steel. AISI 304 offers excellent corrosion resistance and hygiene, while AISI 316L is chosen for enhanced resistance in highly corrosive environments, crucial for longevity and preventing contamination.

- High-Alloy Tool Steel: The cutting knives are forged from specialized high-alloy tool steel, often with tungsten carbide tips or coatings, to ensure exceptional hardness, wear resistance, and edge retention, vital for efficient chopping.

Precision Manufacturing Processes:

- Casting/Forming: The bowl cutter is often formed through deep-drawing or precision casting processes to create a seamless, smooth inner surface, minimizing areas where bacteria can accumulate. This ensures optimal hygiene and facilitates thorough cleaning.

- Forging: Knife blades undergo precision forging, which aligns the grain structure of the steel, imparting superior strength and toughness, critical for resisting impacts during high-speed operation.

- CNC Machining: Advanced Computer Numerical Control (CNC) machining centers are employed for shaping and finishing critical components like the knife shaft, bearing housings, and control panel enclosures. This guarantees extremely tight tolerances, ensuring smooth operation, minimal vibration, and prolonged service life.

- Surface Treatment: Polishing, electropolishing, and passivation treatments are applied to stainless steel surfaces to enhance corrosion resistance, create a smooth, easy-to-clean finish, and improve aesthetic appeal.

- Heat Treatment: Knife blades undergo multi-stage heat treatment processes (hardening, tempering) to achieve the optimal balance of hardness, toughness, and wear resistance, significantly extending their operational lifespan.

Quality Assurance and Testing Standards:

Rigorous quality control protocols are integrated throughout the manufacturing process. Adherence to international standards such as ISO 9001 for quality management and ISO 22000 for food safety is paramount.

- Material Composition Analysis: Spectrographic analysis verifies the chemical composition of raw materials against specifications.

- Dimensional Accuracy: CMM (Coordinate Measuring Machine) inspections ensure all machined parts meet precise dimensional requirements.

- Non-Destructive Testing (NDT): Ultrasonic and dye penetrant testing are used on critical welds and castings to detect internal flaws.

- Performance Testing: Each finished industrial bowl chopper undergoes comprehensive operational testing, including motor performance, knife speed, bowl rotation speed, vacuum integrity (for vacuum models), temperature control, and safety interlocks, validating its adherence to ANSI and CE standards.

The typical service life for a well-maintained industrial meat bowl cutter is often 15-20 years or more, largely due to the robust construction and high-quality components. Target industries benefiting from these highly engineered machines include meat processing, poultry, seafood, dairy, and confectionery, where applications range from fine emulsification for hot dogs to coarse chopping for deli meats. Advantages in typical scenarios include significant energy savings due to optimized motor and knife designs, and superior corrosion resistance, ensuring product purity and extended equipment lifespan.

High-precision manufacturing of a bowl cutter's critical components.

Technical Specifications and Parameters

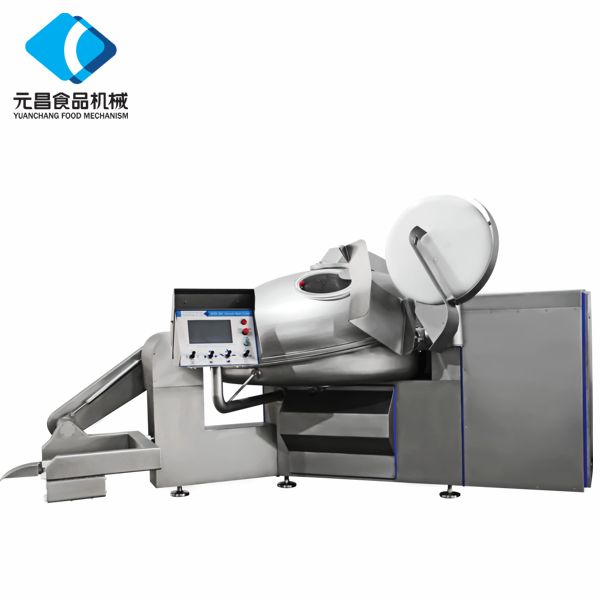

Understanding the technical specifications of a commercial bowl chopper is crucial for matching equipment to specific production needs. Key parameters dictate throughput, product quality, and operational efficiency. Below are typical specifications for the Vacuum Meat Bowl Cutter 125L-750L, which exemplify the high-performance characteristics expected in the industry.

Product Specification Table: Vacuum Meat Bowl Cutter (125L-750L Series)

| Parameter | Description/Range |

|---|---|

| Bowl Volume | 125 Liters to 750 Liters |

| Knife Head Configuration | 3-knife, 6-knife, or 9-knife options |

| Knife Speeds | Variable, typically 1000-4800 RPM (two main speeds + variable frequency drive for fine tuning) |

| Bowl Speeds | Variable, typically 8-16 RPM (two main speeds + variable frequency drive) |

| Main Motor Power | From 30 kW (125L) to 200 kW (750L) |

| Vacuum System Pressure | Adjustable, down to -0.08 MPa (-800 mbar) |

| Control System | PLC with Touch Screen HMI (Siemens, Schneider Electric options) |

| Material | Food-grade Stainless Steel AISI 304/316L |

| Safety Features | Knife cover interlock, motor overload protection, emergency stop |

| Dimensions (Approx.) | Vary by model (e.g., 2000x1600x1800mm for 200L) |

These parameters highlight the engineering sophistication. Variable frequency drives (VFDs) for both knife and bowl speeds allow for precise control over the chopping process, adapting to different raw materials and desired final product textures. The robust motor power ensures consistent performance even with dense product loads, while the integrated vacuum system in a vacuum bowl cutter is crucial for preventing air inclusion, thereby reducing oxidation, enhancing color stability, improving binding properties, and extending shelf life of the processed goods. The adoption of advanced PLC systems with user-friendly Human-Machine Interfaces (HMI) streamlines operation, recipe management, and process monitoring, enhancing both expertise and efficiency on the production floor.

Industry Trends and Innovation in Bowl Chopper Technology

The food processing industry is continuously evolving, driven by consumer demand for healthier, safer, and more diverse products, alongside operational pressures for increased efficiency and reduced environmental impact. These trends directly influence the development of the buffalo chopper bowl.

- Automation and IoT Integration: Modern industrial bowl choppers increasingly feature advanced automation, including robotic loading/unloading systems and integration with plant-wide SCADA or MES systems. IoT capabilities allow for remote monitoring, predictive maintenance, and data analytics, optimizing performance and minimizing downtime.

- Energy Efficiency: With rising energy costs and sustainability goals, manufacturers are focusing on highly efficient motors (e.g., IE3/IE4 rated) and optimized knife geometries that reduce power consumption while maintaining superior chopping performance. Regenerative braking systems also contribute to energy recovery.

- Enhanced Hygiene and Cleanability: Design innovations emphasize smooth surfaces, minimal crevices, and easily removable components for thorough cleaning (CIP/COP compatibility). Features like automatic washing programs and improved sealing reduce contamination risks and ensure compliance with stringent food safety regulations like HACCP and FDA guidelines.

- Versatility in Product Processing: Manufacturers are developing more versatile machines, such as the double bowl chopper, which offer greater flexibility in batch processing or sequential tasks. These machines can handle a broader range of raw materials, from delicate vegetables to tough meat cuts, accommodating diverse product lines. The capacity to switch between different knife configurations rapidly is also becoming a standard feature.

- Temperature Control: Precise temperature management during chopping is critical. Advanced bowl cutters feature integrated cooling systems (e.g., liquid nitrogen or CO2 injection, jacketed bowls with chilled water circulation) to prevent heat buildup, preserving protein structure, flavor, and color, particularly for sensitive meat emulsions.

Operator interface showcasing modern bowl chopper controls and automation features.

Application Scenarios and Case Studies

The adaptability and efficiency of the industrial meat bowl cutter make it indispensable across a spectrum of food processing operations. Its ability to create various textures, from coarse to ultra-fine, under controlled conditions, underpins its wide adoption.

Typical Application Scenarios:

- Meat Processing: Production of emulsified sausages (frankfurters, bologna), fine pâtés, spreads, and restructured meat products. The vacuum function significantly improves color, binding, and sliceability.

- Poultry and Fish Processing: Creation of nuggets, fish cakes, surimi, and other value-added comminuted products.

- Dairy and Cheese Production: Processing of processed cheese, cheese spreads, and other dairy-based emulsions requiring smooth, consistent texture.

- Vegetable and Plant-Based Foods: Fine chopping of vegetables for purees, dips, sauces, and plant-based meat alternatives, often utilizing a vegetable slicer with bowl configuration.

- Confectionery: Grinding nuts, seeds, and fruits for fillings, pastes, and confectionery ingredients.

Application Case Study: Large-Scale Sausage Production Facility

A leading European meat processor faced challenges in achieving consistent emulsion quality and optimizing production throughput for its premium frankfurter line. Their existing equipment, a standard bowl cutter, struggled with temperature control and air inclusion, leading to occasional product defects and reduced shelf life.

Solution Implemented: The facility upgraded to a 500L Vacuum Meat Bowl Cutter (similar to the YCMeatMech series). This machine featured a powerful main motor, a high-efficiency vacuum system capable of reaching -0.08 MPa, and advanced PLC control for precise recipe management. Integrated CO2 injection cooling ensured optimal processing temperatures.

Results Achieved:

- Product Quality Improvement: Emulsion stability increased by 15%, resulting in a smoother texture and reduced fat separation. The vacuum process eliminated air pockets, enhancing color uniformity and reducing spoilage rates.

- Increased Throughput: Optimized knife and bowl speeds, combined with faster loading/unloading, led to a 20% increase in daily production capacity.

- Extended Shelf Life: Removal of oxygen through the vacuum system extended product shelf life by 3 days, reducing waste and expanding distribution capabilities.

- Energy Efficiency: The high-efficiency motor and optimized process parameters resulted in a 10% reduction in energy consumption per batch.

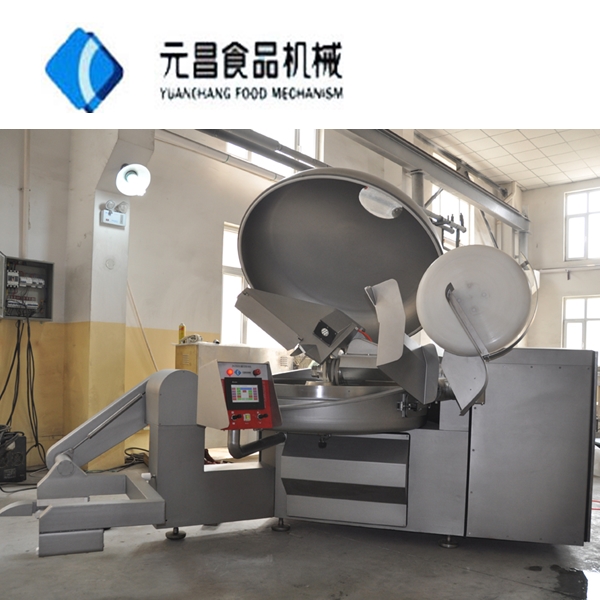

Vacuum meat bowl cutter in operation within a modern food processing plant.

This case exemplifies how investing in an advanced industrial bowl chopper can yield significant improvements in both operational efficiency and final product quality, directly impacting profitability and market competitiveness.

Technical Advantages of Advanced Bowl Cutters

Modern industrial buffalo chopper bowl systems offer a suite of technical advantages that set them apart from conventional processing equipment, directly impacting product quality, operational costs, and worker safety.

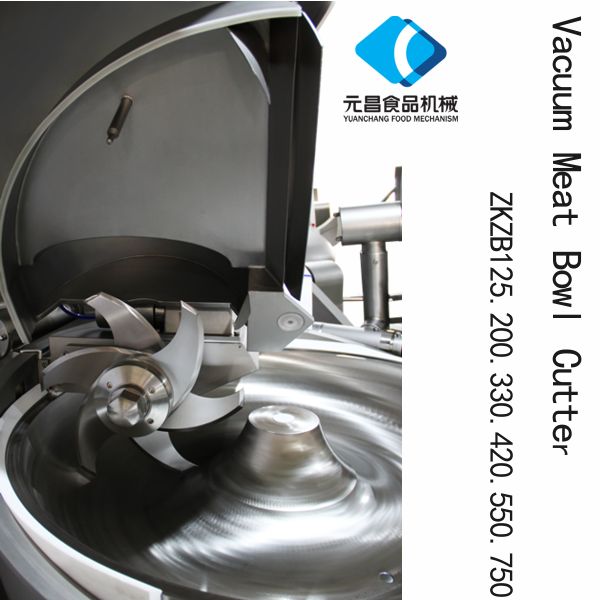

- Superior Emulsification and Texture Control: High-speed, precision-engineered knife systems combined with variable bowl speeds allow for incredibly fine particle size reduction and superior emulsification, producing smooth, homogenous products with desired textural attributes. The ability to control chopping intensity is unmatched.

- Enhanced Product Yield: Optimized cutting action minimizes material loss and maximizes the incorporation of raw ingredients into the final product. The vacuum function further improves binding properties, reducing cooking losses and improving overall yield.

- Advanced Temperature Management: Integrated cooling systems (e.g., direct CO2/liquid nitrogen injection, jacketed bowls) prevent heat buildup during high-speed chopping. This is crucial for preserving protein structure, preventing fat separation, and maintaining the desired color and flavor profile of temperature-sensitive products.

- Corrosion Resistance and Hygiene: Constructed entirely from high-grade AISI 304 or 316L stainless steel, these machines offer exceptional resistance to corrosion from processing ingredients and cleaning agents. Smooth, polished surfaces and accessible designs facilitate thorough cleaning and sanitation, meeting the strictest HACCP and USDA hygiene standards.

- Energy Efficiency: Modern bowl cutters incorporate high-efficiency motors (e.g., IE3/IE4) and intelligent control systems that optimize power consumption based on load. Variable Frequency Drives (VFDs) enable precise speed control, further contributing to energy savings compared to fixed-speed legacy machines.

- Operator Safety and Ergonomics: Comprehensive safety features, including knife cover interlocks, emergency stops, and advanced braking systems, protect operators. Ergonomic designs, such as automated loading and unloading, reduce manual labor and the risk of injury.

- Reduced Oxidation and Improved Shelf Life (Vacuum Models): The vacuum feature is a critical advantage, removing air from the product during processing. This minimizes oxidation, which can cause color degradation (e.g., graying in meat), off-flavors, and microbial spoilage. Products processed under vacuum typically exhibit better color stability, improved sensory attributes, and significantly extended shelf life, especially when using a vacuum bowl cutter.

Detail view of the robust knife head and bowl for maximum processing efficiency.

Vendor Comparison and Selection Criteria

Selecting the right industrial bowl chopper involves a thorough evaluation of various vendors and their offerings. Key criteria extend beyond initial purchase price to encompass long-term operational costs, reliability, and support.

Key Evaluation Criteria:

- Technology and Innovation: Assess the integration of advanced features like VFDs, vacuum systems, intelligent control (PLC/HMI), and automation capabilities.

- Build Quality and Materials: Verify the grade of stainless steel (e.g., AISI 304, 316L), robustness of the frame, precision of machining, and quality of knife materials. Certifications like ISO 9001 and CE mark are good indicators.

- Performance and Efficiency: Compare motor power, knife speeds, bowl speeds, vacuum strength, and reported energy consumption figures. Request performance data or conduct trials with your specific products.

- Hygiene and Safety: Evaluate design for ease of cleaning (e.g., open frame, smooth welds, removable components), and the presence of comprehensive safety interlocks and emergency stop mechanisms. Compliance with FDA, USDA, and European food safety standards is critical.

- After-Sales Support and Spare Parts: The availability of technical support, spare parts, and service technicians is crucial for minimizing downtime. Inquire about warranty periods and service contracts.

- Customization Options: The ability to tailor machine specifications (e.g., bowl size, knife configuration, loading/unloading systems, control panel language) to specific plant layouts and product requirements.

- Total Cost of Ownership (TCO): Consider not just the purchase price but also energy consumption, maintenance costs, expected lifespan, and the cost and availability of spare parts over the machine's lifetime.

Vendor Comparison: Standard vs. Premium Industrial Bowl Choppers

| Feature/Aspect | Standard Bowl Cutter | Premium Industrial Bowl Chopper (e.g., YCMeatMech Vacuum) |

|---|---|---|

| Bowl Material | AISI 304 Stainless Steel, basic finish | AISI 304/316L Stainless Steel, electropolished, seamless construction |

| Knife Drive | Fixed 2-speed motor | Variable Frequency Drive (VFD) for infinite speed control (1000-4800 RPM) |

| Bowl Drive | Fixed 2-speed motor | VFD for variable speed control (8-16 RPM) |

| Vacuum System | Often absent, or basic external system | Integrated, high-efficiency vacuum pump (-0.08 MPa), adjustable |

| Control Panel | Analog buttons/switches | PLC with Siemens/Schneider Touch Screen HMI, recipe management |

| Cooling System | Manual ice addition or basic jacket | Integrated CO2/N2 injection or chilled water jacket with automated control |

| Automation & Safety | Basic safety features | Advanced interlocks, motor protection, automatic loading/unloading options, CIP compatibility |

| Energy Efficiency | Standard motors | High-efficiency IE3/IE4 motors, VFDs for optimized power usage |

This comparison highlights that while a standard bowl cutter may suffice for basic needs, a premium industrial bowl chopper offers significant advantages in precision, efficiency, product quality, and long-term cost-effectiveness, justifying the higher initial investment.

Customized Solutions and Engineering

For many B2B clients, off-the-shelf equipment may not perfectly align with unique production requirements, facility constraints, or specialized product formulations. This is where customized solutions for the buffalo chopper bowl become invaluable. Leading manufacturers recognize this need and offer extensive engineering capabilities to adapt their standard offerings or design bespoke systems.

- Tailored Capacities: While standard models range from 125L to 750L, specific projects may require intermediate sizes or even larger industrial bowl cutter units. Custom bowl volumes can be engineered to optimize batch sizes and process flow within an existing production line.

- Specialized Knife Configurations: Different products benefit from specific knife types and arrangements. Customization can include specialized knife materials (e.g., ceramic-reinforced for abrasive products), unique knife geometries for particular emulsification requirements, or a combination of cutting and mixing blades for complex formulations.

- Integrated Loading/Unloading Systems: To enhance efficiency and ergonomics, bowl cutters can be integrated with automated loading hoists, conveyor systems, or pneumatic discharge systems tailored to the client's material handling infrastructure.

- Advanced Control Integration: Customization extends to the control system, allowing for seamless integration with existing plant automation, specific recipe management software, and unique sensor inputs for real-time monitoring of parameters like pH, conductivity, or viscosity during processing.

- Temperature Control Systems: Beyond standard cooling, bespoke solutions might involve specialized chilling jackets for specific refrigerants, multi-point temperature probes, or precise liquid nitrogen/CO2 injection systems with automated dosage based on product characteristics.

- Compliance with Regional Standards: Manufacturers can adapt designs and components to meet specific regional electrical codes (e.g., UL, CSA), pressure vessel regulations, or hygiene standards (e.g., EHEDG).

A specialized bowl cutter design, customized for unique production demands.

Working with a vendor offering strong R&D and engineering support is critical for successful customization. This ensures that the modified or bespoke valve bowl cutter not only meets technical specifications but also integrates flawlessly into the existing production environment and delivers the desired processing outcomes efficiently and reliably.

Ensuring Trustworthiness: Quality, Support, and Warranty

Trustworthiness is a cornerstone of B2B relationships, particularly when investing in critical processing equipment like an industrial meat bowl cutter. Manufacturers build trust through transparent practices regarding quality, robust customer support, and clear warranty commitments.

Quality Assurance and Certifications:

Our products, including the Vacuum Meat Bowl Cutter 125L-750L, adhere to strict international quality and safety standards.

- ISO 9001: Certified quality management system ensuring consistent product quality.

- CE Marking: Compliance with European health, safety, and environmental protection standards.

- HACCP/FDA Compatibility: Designed and constructed to meet the hygienic requirements for food contact equipment, supporting clients' HACCP plans and FDA regulations.

- Material Traceability: Full traceability of all food-grade stainless steel used, from mill to final product.

Lead Time and Fulfillment:

Standard models typically have a lead time of 6-8 weeks, depending on current production schedules and customization requirements. For highly customized or very large-volume double bowl chopper systems, lead times may extend to 10-14 weeks. We provide transparent communication on delivery schedules from order confirmation to shipment. Rigorous pre-shipment inspections and robust packaging ensure the equipment arrives in optimal condition.

Warranty Commitments:

All our Vacuum Meat Bowl Cutters come with a standard 12-month warranty covering manufacturing defects and component failures under normal operating conditions. Extended warranty options and comprehensive service contracts are available for clients seeking additional peace of mind and long-term operational guarantees. Specific terms and conditions are provided with each quotation.

Customer Support and After-Sales Service:

- Technical Assistance: Dedicated technical support team available for troubleshooting, operational guidance, and process optimization.

- Spare Parts Availability: A comprehensive inventory of genuine spare parts is maintained, ensuring quick dispatch to minimize downtime. Critical components are often stocked regionally.

- On-Site Service: Skilled technicians are available for installation, commissioning, preventative maintenance, and emergency repairs globally.

- Training Programs: We offer operator and maintenance training to ensure your team is proficient in operating and maintaining the equipment safely and efficiently.

Frequently Asked Questions (FAQ):

- Q: What is the optimal temperature range for chopping meat in a buffalo chopper bowl?

- A: For most meat emulsions, maintaining a core temperature between 0°C to 4°C (32°F to 39°F) is ideal to prevent protein denaturation and fat smearing. Our machines offer precise temperature control mechanisms to achieve this.

- Q: How often should the knives be sharpened or replaced?

- A: The frequency depends on product abrasiveness and usage intensity. Generally, knives should be inspected daily and sharpened or replaced according to manufacturer guidelines and visible wear signs. Our high-alloy steel knives are designed for extended life but proper maintenance is key.

- Q: Can your bowl cutters process both meat and vegetables?

- A: Yes, our versatile designs are capable of processing a wide range of ingredients. For strict segregation, a dedicated vegetable slicer with bowl or thorough cleaning protocols are recommended to prevent cross-contamination.

- Q: What are the benefits of a vacuum bowl cutter over a standard one?

- A: A vacuum bowl cutter prevents air inclusion, which leads to improved product color, enhanced binding properties, reduced oxidation, and significantly extended shelf life. It also results in a denser, more uniform product texture.

Conclusion

The industrial buffalo chopper bowl is a vital piece of equipment for any modern food processing operation demanding precision, hygiene, and efficiency. From the meticulous selection of food-grade materials and advanced manufacturing processes like CNC machining, through rigorous testing to meet ISO and ANSI standards, every aspect of its production is geared towards delivering reliability and superior performance. Innovations in automation, energy efficiency, and vacuum technology continue to enhance its capabilities, enabling processors to meet evolving consumer demands and regulatory requirements.

By understanding the technical specifications, leveraging advanced features, and partnering with reputable manufacturers offering strong support and customization options, businesses can unlock significant improvements in product quality, operational throughput, and overall profitability. The investment in a high-quality, technically advanced bowl cutter is an investment in the future success and competitiveness of a food processing enterprise.

References

- Food and Agriculture Organization of the United Nations (FAO). "Meat Processing Technology." Available at: www.fao.org/ag/agn/agns/meat_processing_en.htm

- International Organization for Standardization (ISO). "ISO 9001: Quality management systems." Available at: www.iso.org/iso-9001-quality-management.html

- U.S. Food and Drug Administration (FDA). "Food Safety Modernization Act (FSMA)." Available at: www.fda.gov/food/guidance-regulation-food-and-dietary-supplements/food-safety-modernization-act-fsma

- European Hygienic Engineering & Design Group (EHEDG). "Hygienic Design of Food Processing Equipment." Available at: www.ehedg.org

- Meat & Poultry Magazine. "The Science of Emulsification." (Industry publication, specific article varies by issue)

-

Meat Portioning Machine: Precision, Efficiency & Sustainability in Meat ProcessingNewsNov.24,2025

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025