- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

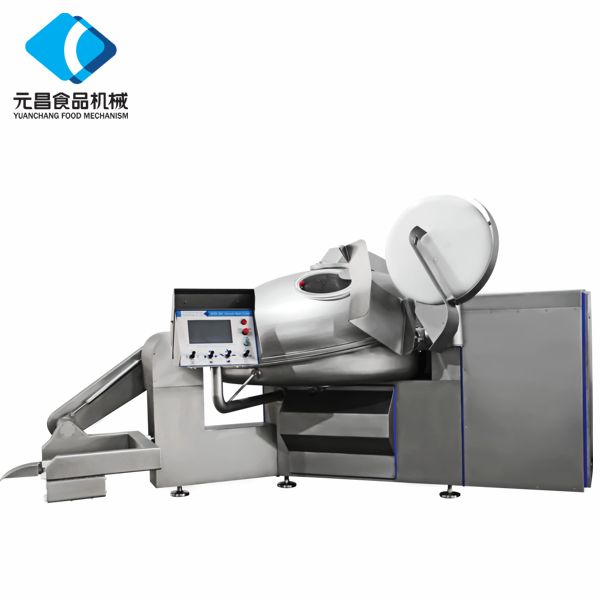

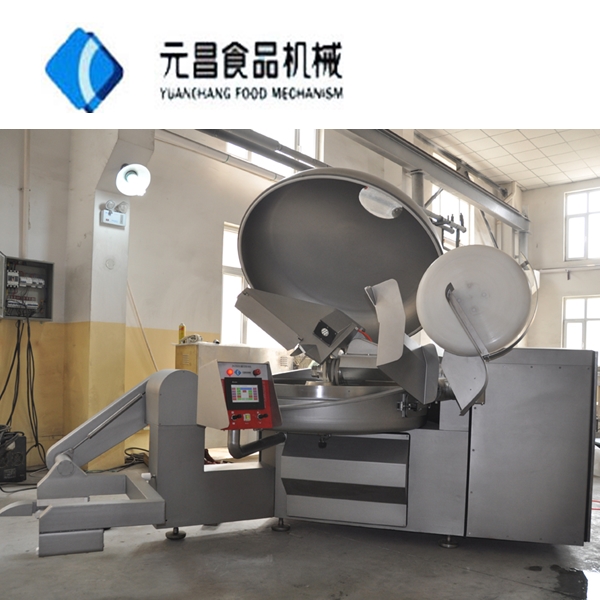

Buffalo Chopper Bowl: High-Efficiency Commercial Meat & Veg Slicer

Advancing Food Processing with High-Performance Bowl Cutters

In the demanding landscape of modern food production, precision, hygiene, and efficiency are paramount. Central to achieving these objectives, particularly in meat and specialized food processing, is the sophisticated machinery known as the bowl cutter. This article delves into the intricacies of the buffalo chopper bowl, examining its critical role, advanced technical specifications, diverse applications, and the strategic advantages it offers to B2B stakeholders. From small-scale commercial operations to large-volume industrial facilities, the evolution of bowl cutter technology continues to redefine standards for product quality and operational output.

We will explore the underlying manufacturing processes, highlight key industry trends, present comparative data, and discuss customized solutions, providing a comprehensive overview for decision-makers and technical professionals alike.

Industry Trends in Bowl Cutter Technology

The food processing industry is experiencing rapid innovation driven by consumer demands for healthier, safer, and more diverse products, alongside operational pressures for increased efficiency and reduced waste. Key trends impacting bowl cutter technology include:

- Automation and Integration: Modern bowl cutters are increasingly integrated into fully automated production lines, featuring programmable logic controllers (PLCs) and intuitive human-machine interfaces (HMIs) for seamless operation and reduced manual labor.

- Enhanced Hygiene and Sanitation: With stringent food safety regulations, designs emphasize smooth surfaces, easy-to-clean components (e.g., all stainless steel 304/316L construction), and Clean-in-Place (CIP) capabilities to prevent cross-contamination.

- Vacuum Technology: The rise of the vacuum bowl cutter is significant. Processing under vacuum minimizes air incorporation, preventing oxidation, preserving natural color, improving product texture, and extending shelf life. This is particularly crucial for premium meat products.

- Energy Efficiency: Manufacturers are developing models with optimized motor performance, variable frequency drives (VFDs), and intelligent power management systems to reduce energy consumption and operational costs.

- Versatility and Multi-functionality: Modern bowl cutters are not just for meat; they can function as a high-performance vegetable slicer with bowl for processing produce, or for emulsions in the dairy and confectionery sectors, showcasing their adaptability.

- Smart Monitoring and Predictive Maintenance: Sensors and IoT integration allow for real-time monitoring of operational parameters, enabling predictive maintenance, minimizing downtime, and optimizing performance.

Detailed Process Flow of a Bowl Cutter Manufacturing

The manufacturing of a high-quality industrial meat bowl cutter involves a meticulous process to ensure durability, precision, and hygiene.

Schematic Steps of Manufacturing a Bowl Cutter:

-

Material Selection and Preparation:

High-grade stainless steel, typically AISI 304 or 316L, is selected for all food-contact surfaces and structural components due to its excellent corrosion resistance, hygiene properties, and mechanical strength. Raw materials undergo rigorous inspection to meet industry standards (e.g., ASTM A240 for stainless steel sheets).

-

Precision Casting and Forging:

Critical components such as the bowl itself, knife heads, and certain structural parts are precision-cast or forged to achieve optimal strength and structural integrity. Forging is often used for knife shafts to ensure superior hardness and resistance to wear.

-

CNC Machining:

Advanced CNC (Computer Numerical Control) machining centers are employed to fabricate parts with extremely tight tolerances. This includes the precise shaping of the bowl, milling of motor housings, and intricate detailing of the knife assembly to ensure perfect balance and fit, crucial for the high-speed operation of a double bowl chopper.

-

Welding and Assembly:

Skilled technicians perform TIG (Tungsten Inert Gas) welding for strong, smooth, and crevice-free joints, particularly important for hygiene in food processing equipment. Components are then systematically assembled, including motors, gearboxes, vacuum pumps, control panels, and the critical blade system.

-

Surface Treatment and Finishing:

Surfaces are meticulously polished to a fine finish (e.g., Ra < 0.8 µm), eliminating microscopic imperfections where bacteria could harbor. Passivation processes are applied to enhance corrosion resistance, especially for exposure to acidic or alkaline cleaning agents.

-

Testing and Quality Assurance:

Each unit undergoes stringent testing. This includes functional tests of all mechanical and electrical systems, vacuum integrity tests for vacuum models, noise level measurements, and safety interlock verification. Testing standards adhere to international benchmarks such as ISO 9001 for quality management, CE for European market conformity, and often FDA guidelines for food contact materials.

-

Final Inspection and Documentation:

A final comprehensive inspection ensures all specifications are met. Detailed documentation, including operational manuals, maintenance guides, and parts lists, accompanies each machine.

Service Life and Target Industries:

A well-maintained commercial bowl chopper, manufactured to these standards, typically boasts a service life of 15-20 years or more. Target industries include: meat processing (sausages, pates, restructured meats), poultry and fish processing, vegetable processing, dairy (processed cheese, butter blends), and pet food manufacturing.

Advantages in Typical Application Scenarios:

- Energy Saving: Modern designs optimize motor efficiency and blade aerodynamics, reducing power consumption per batch.

- Corrosion Resistance: Extensive use of AISI 304/316L stainless steel ensures longevity in harsh processing environments, resistant to acids, salts, and cleaning chemicals.

- Enhanced Product Quality: Precision cutting and emulsification lead to superior texture, binding, and appearance of finished products. Vacuum models further enhance color stability and extend shelf life.

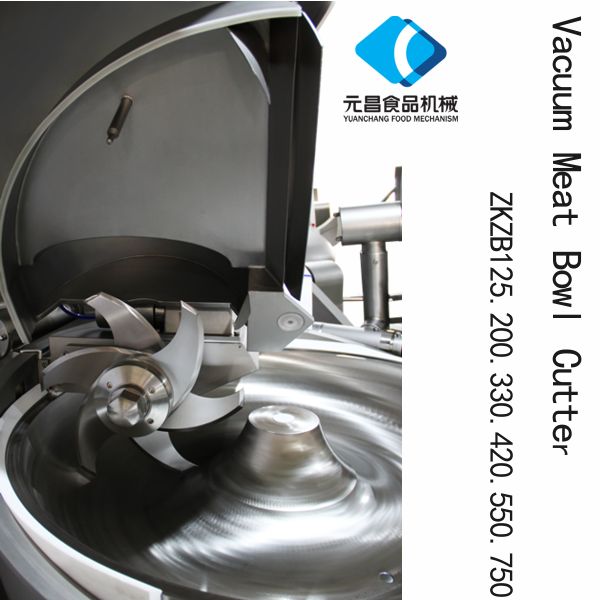

Technical Specifications of Vacuum Meat Bowl Cutter (125L-750L)

The "Vacuum Meat Bowl Cutter 125L-750L" series represents a pinnacle in food processing technology, designed for high-volume, precision emulsification. Key parameters define its robust performance and versatility.

Product Specification Table: Vacuum Meat Bowl Cutter Series

| Parameter | 125L Model | 200L Model | 330L Model | 500L Model | 750L Model |

|---|---|---|---|---|---|

| Bowl Volume (L) | 125 | 200 | 330 | 500 | 750 |

| Main Motor Power (kW) | 30-45 | 55-75 | 90-110 | 132-160 | 200-250 |

| Knife Shaft Speed (RPM) | 1500-4500 (variable) | 1500-4500 (variable) | 1500-4800 (variable) | 1500-5000 (variable) | 1500-5000 (variable) |

| Bowl Speed (RPM) | 8-20 (variable) | 8-20 (variable) | 8-20 (variable) | 8-20 (variable) | 8-20 (variable) |

| Vacuum Pump Power (kW) | 2.2 | 4.0 | 5.5 | 7.5 | 11 |

| Vacuum Level (mbar) | <100 | <100 | <100 | <100 | <100 |

| Material | Food-grade AISI 304/316L Stainless Steel | ||||

| Control System | PLC with Touchscreen HMI | ||||

| Blades | Customizable (3 or 6 blade configurations), hardened stainless steel | ||||

| Cooling System | Integrated (e.g., liquid nitrogen or CO2 injection capable) | ||||

Application Scenarios and Experience

The versatility of an industrial bowl chopper makes it indispensable across various food sectors:

- Meat Processing: Production of fine meat emulsions for sausages (frankfurters, bologna), hot dogs, pates, luncheon meats, and restructured meat products. The precise cut and emulsification are critical for texture and binding.

- Poultry and Fish Processing: Creating smooth pastes for fish balls, surimi, and poultry products, ensuring homogenous mixing and desired consistency.

- Vegetable Processing: Chopping and emulsifying vegetables for purees, dips, sauces, and bases. This is where a vegetable slicer with bowl capability shines, offering fine control over particle size.

- Dairy and Confectionery: Preparing processed cheese spreads, butter blends, and various confectionery fillings, where smooth, air-free textures are essential.

- Baby Food and Healthcare: Producing finely ground and emulsified ingredients for pureed foods, requiring the highest levels of hygiene and particle size control.

Customer feedback consistently highlights the impact of these machines on product consistency and operational throughput. One major European meat processor reported a 15% improvement in emulsion stability and a 20% reduction in processing time after implementing a vacuum bowl cutter, directly leading to increased yield and reduced waste.

Technical Advantages and Performance

The advantages of advanced bowl cutter technology, especially those incorporating vacuum processing, are multifaceted:

- Superior Emulsification and Particle Size Control: High-speed, precision-engineered blades working in conjunction with a rotating bowl ensure incredibly fine and uniform particle reduction, critical for stable emulsions and desired product texture. Knife tip speeds can exceed 100 m/s.

- Temperature Management: Integrated temperature probes and optional cooling systems (e.g., liquid nitrogen or CO2 injection) prevent heat buildup during high-speed cutting, preserving raw material quality and preventing protein denaturation.

- Vacuum Processing Benefits: Processing under vacuum (typical vacuum level <100 mbar) significantly enhances product quality by:

- Preventing oxidation, which maintains natural color and flavor.

- Reducing air pockets, leading to denser, smoother textures and fewer quality defects.

- Extending shelf life by minimizing microbial growth factors.

- Robust Construction: Manufactured with heavy-duty stainless steel (AISI 304/316L) and robust mechanical components, these machines are built for continuous operation in harsh industrial environments, offering exceptional longevity. This makes them ideal as an industrial bowl chopper.

- Advanced Safety Features: Comprehensive safety interlocks, emergency stops, and bowl cover detection systems protect operators and comply with international safety standards like EN ISO 12100.

- Ease of Cleaning: Smooth, polished surfaces and accessible components facilitate quick and thorough cleaning, upholding stringent HACCP and GMP requirements.

Vendor Comparison and Customization Options

When selecting a bowl cutter, enterprises evaluate vendors based on technology, quality, support, and customization capabilities. Here's a comparative look at key differentiators:

Product Comparison Table: Bowl Cutter Features

| Feature | Leading Manufacturer (e.g., YC Meat Mech) | Standard Competitor |

|---|---|---|

| Vacuum System Integration | Standard on high-volume models; high-efficiency pump, <100 mbar | Optional or less efficient; <200 mbar typical |

| Blade Configuration | 3 or 6 knives, hardened steel, dynamic balancing, quick-change system | Fixed 3 knives, standard steel, manual balancing |

| Control System | Advanced PLC with intuitive HMI, recipe management, remote diagnostics | Basic push-button control, limited programmability |

| Material Construction | AISI 304/316L Stainless Steel throughout, mirror-polished food contact surfaces | AISI 304 for food contact, painted mild steel for frame, brushed finish |

| Energy Efficiency | IE3/IE4 motors, VFDs for all main drives, optimized power consumption | Standard IE2 motors, single-speed drives |

| After-Sales Support | Global network, 24/7 technical support, extensive spare parts inventory, preventative maintenance programs | Regional support, limited spare parts, reactive maintenance |

Customized Solutions:

Leading manufacturers understand that one size does not fit all. Customization options for the buffalo chopper bowl can include:

- Capacity Adjustments: Tailoring bowl volumes to specific production needs, beyond standard ranges.

- Specialized Blade Designs: Developing blade geometries for unique product textures, from coarse chop to ultra-fine emulsions. This might include specific hardened alloys for challenging ingredients.

- Integrated Feeding and Discharging Systems: Designing seamless integration with upstream mixers, grinders, and downstream filling or forming equipment.

- Advanced Temperature Control: Integrating direct steam injection, jacketed bowls for heating/cooling, or enhanced cryogen systems.

- Remote Monitoring and Control: Options for integration into existing plant-wide SCADA systems for centralized control and data analytics.

- Compliance with Regional Standards: Ensuring specific certifications or material requirements are met for target markets (e.g., USDA, EAC).

Application Case Studies

Real-world implementations demonstrate the tangible benefits of high-performance bowl cutters:

-

Case Study 1: Large-Scale Sausage Production

A leading North American meat packer upgraded its processing line with a 750L vacuum bowl cutter. Previously, they struggled with inconsistent emulsion texture and product discoloration due to air entrapment. Post-installation, the vacuum system eliminated oxidation, resulting in brighter, more appealing products with extended shelf life. The high-speed blades and precise temperature control led to a 7% increase in binding capacity, significantly reducing rework and improving overall yield by 3% within the first six months. The consistency of the emulsion also allowed for higher speed stuffing operations, increasing line throughput by 10%.

-

Case Study 2: Premium Pet Food Manufacturing

A specialized European pet food producer, focusing on high-protein, pureed products, integrated a 330L commercial bowl chopper. Their primary challenge was achieving a perfectly smooth, homogenous puree from mixed meat and vegetable ingredients without compromising nutritional value through excessive heat. The advanced temperature monitoring and CO2 injection capabilities of the new machine ensured that the product remained within optimal processing temperatures, preserving vitamins and minimizing protein degradation. This resulted in a premium product that met strict quality controls and commanded a higher market price.

-

Case Study 3: Plant-Based Protein Processing

A rapidly growing Asian plant-based food company sought a solution to create finely textured, meat-analogue products from various vegetable proteins. A customized 200L industrial bowl chopper, equipped with specialized blade geometry for fibrous materials and a robust valve bowl cutter mechanism for precise ingredient addition, was deployed. This allowed them to achieve the desired fibrous-yet-homogenous texture previously unattainable with conventional choppers. The enhanced texture and mouthfeel significantly improved consumer acceptance of their new line of plant-based sausages.

Frequently Asked Questions (FAQ)

- Q: What is the primary advantage of a vacuum bowl cutter over a standard bowl cutter?

- A: The primary advantage is the processing of ingredients in an oxygen-free environment. This prevents oxidation, preserves the natural color and flavor of the product, improves emulsion stability, and extends shelf life by inhibiting bacterial growth and enzymatic reactions. Products are denser, have fewer air bubbles, and exhibit superior texture.

- Q: How often do the blades need to be sharpened or replaced for an industrial meat bowl cutter?

- A: The frequency depends on the type of product, usage intensity, and blade material. High-quality hardened stainless steel blades typically maintain sharpness for several hundred operating hours. Regular inspection and professional sharpening services are recommended. Replacement is necessary when blades show significant wear or damage, usually every few years under normal operation.

- Q: Can a bowl cutter process frozen meat?

- A: Yes, many industrial bowl cutters are designed to handle partially frozen meat blocks (e.g., down to -4°C to -8°C). However, the optimal processing temperature for finely emulsified products is typically closer to 0°C to 4°C to prevent excessive heat buildup and ensure proper protein extraction. For heavily frozen blocks, a frozen meat grinder or block cutter is recommended as a pre-processing step.

- Q: What power requirements are typical for a large-capacity (e.g., 500L) buffalo chopper bowl?

- A: For a 500L model, the main motor power can range from 132 kW to 160 kW, depending on the desired knife speed and processing intensity. Additional power is required for the bowl drive (typically 2.2-4 kW), vacuum pump (7.5 kW), and auxiliary systems like discharge and cooling. Proper electrical infrastructure is crucial for installation and efficient operation.

Lead Time, Warranty, and Customer Support

Understanding the post-purchase commitment is crucial for B2B investments.

Lead Time and Fulfillment:

Typical lead times for standard models of the Vacuum Meat Bowl Cutter (125L-750L) range from 8-12 weeks, depending on current production schedules and customization requirements. For highly customized solutions, lead times may extend to 16-20 weeks. Our fulfillment process includes factory acceptance testing (FAT), secure packaging, and efficient logistics to ensure timely and safe delivery to the client's facility. On-site installation and commissioning services by our certified engineers are available globally.

Warranty Commitments:

We provide a comprehensive warranty of 12-24 months on all major components and manufacturing defects from the date of installation or commissioning, whichever comes later. This warranty covers parts and labor, reflecting our confidence in the quality and reliability of our bowl cutter machines. Extended warranty options are also available upon request.

Customer Support and After-Sales Service:

Our commitment extends beyond delivery. We offer:

- 24/7 Technical Support: A dedicated support team available via phone, email, and remote diagnostics to address operational queries and troubleshoot issues promptly.

- Spare Parts Availability: A vast inventory of genuine spare parts ensures minimal downtime. Critical wear parts are stocked locally in key markets.

- Preventative Maintenance Programs: Tailored service contracts to ensure optimal performance, extended machine life, and compliance with hygiene standards.

- Training Services: On-site or remote training for your operational and maintenance staff to ensure proficient use and care of the equipment.

Certifications and Authoritative References

Our commitment to quality and safety is underlined by adherence to international standards and certifications:

- ISO 9001:2015: Certified quality management system ensuring consistent product quality and customer satisfaction.

- CE Mark: All equipment complies with European Union safety, health, and environmental protection requirements.

- FDA Compliance: Materials and design conform to U.S. Food and Drug Administration guidelines for food contact surfaces.

- HACCP & GMP Principles: Our equipment design and manufacturing processes are fully compatible with Hazard Analysis and Critical Control Points (HACCP) and Good Manufacturing Practices (GMP).

These certifications, combined with rigorous internal testing and collaboration with renowned food technology institutes, underscore the authoritativeness and reliability of our bowl cutter solutions.

Conclusion

The modern buffalo chopper bowl is far more than a simple chopping machine; it is a sophisticated piece of engineering essential for achieving superior product quality and operational efficiency in diverse food processing applications. Its continuous evolution, driven by advancements in vacuum technology, automation, and hygiene standards, positions it as a critical investment for businesses aiming to excel in competitive markets. By understanding the intricate manufacturing processes, leveraging precise technical specifications, and embracing customized solutions, food processors can unlock unprecedented levels of consistency, safety, and profitability.

Citations

- Food and Agriculture Organization of the United Nations (FAO). "Meat Processing Technology for Small and Medium Scale Producers." Available at: www.fao.org/ag/ags/agse/meat_processing.htm

- European Hygienic Engineering & Design Group (EHEDG). "Hygienic Design of Equipment for Food Processing." Available at: www.ehedg.org

- Institute of Food Technologists (IFT). "Food Technology Magazine." Various issues on meat science and processing. Available at: www.ift.org

- International Organization for Standardization (ISO). "ISO 22000: Food safety management systems." Available at: www.iso.org

-

Filling Flow Divider - Precision, Hygienic Multiline DosingNewsNov.18,2025

-

Hopper Trolley: Heavy-Duty, Ergonomic, Easy DischargeNewsNov.18,2025

-

Frozen Meat Slicer for Ultra-Thin, Precise, Safe CutsNewsNov.17,2025

-

Smoke House Machine | Precise, Energy-Efficient, HACCP-ReadyNewsNov.17,2025

-

Smoke House Machine: Uniform, Energy-Efficient SmokingNewsNov.11,2025

-

Meat Filling Machine - Stainless, Precise, High OutputNewsNov.11,2025