- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

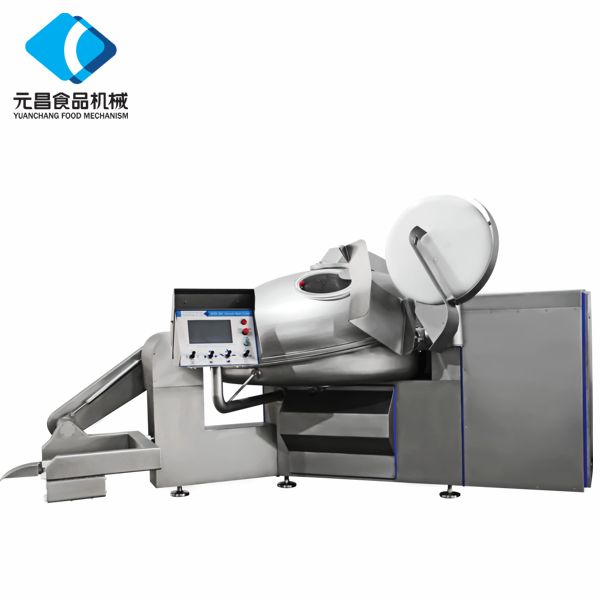

Buffalo Chopper Bowl – Heavy-Duty, Hygienic, Easy-Clean

Bowl Cutter is a key solution in the manufacturing industry, specifically within Special Equipment Manufacturing Industry and Manufacturing of specialized equipment for food, beverage, tobacco, and feed production. This article explores how Hebei Yuanchang Food Mechanism & Technology Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Bowl Cutter Overview

- Benefits & Use Cases of Bowl Cutter in Manufacturing of specialized equipment for food, beverage, tobacco, and feed production

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Bowl Cutter from Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

Bowl Cutter Overview

A Bowl Cutter—often called a bowl cutter, commercial bowl chopper, or industrial meat bowl cutter—is a high-torque, high-speed mixing and cutting system that emulsifies, chops, and blends proteins, vegetables, and additives into uniform pastes or finely comminuted mixes. In the Special Equipment Manufacturing Industry, it is indispensable for sausage, deli meats, plant-based proteins, spreads, pet food, and feed formulations requiring precise particle size and consistent texture. Hebei Yuanchang Food Mechanism & Technology Co., Ltd. engineers vacuum bowl cutter solutions in capacities suited to mid- and large-scale processors, helping streamline batch consistency while safeguarding product quality.

Technically, the system combines a rotating bowl with high-speed knives to cut and emulsify under controlled temperature and vacuum, reducing oxidation and improving protein extraction. Options like a double bowl chopper configuration, variable-speed drives, and PLC recipe controls increase throughput and repeatability. For facilities that also handle produce, pairing with a vegetable slicer with bowl can extend functionality to vegetables, cheese, and ready-meal components. Backed by rigorous fabrication standards and process know-how, Hebei Yuanchang delivers robust equipment that integrates into new or retrofit lines with minimal disruption and a focus on hygiene and cleanability.

Benefits & Use Cases of Bowl Cutter in Manufacturing of specialized equipment for food, beverage, tobacco, and feed production

Across food, beverage, tobacco, and feed production, the Bowl Cutter unlocks repeatable particle-size control and fast emulsification. In meat and plant-based categories, processors achieve smooth batters for frankfurters, bologna, and vegan sausages. In dairy and prepared foods, it produces uniform cheese slurries, pâtés, hummus, and sauces. For pet food and animal feed, it handles viscous, protein-rich mixes where homogeneity and nutrition delivery are critical. In tobacco-related processes, a vacuum-capable valve bowl cutter supports stable, uniform blends where low-oxygen conditions help preserve color and volatiles.

- Vacuum performance: The vacuum bowl cutter limits air inclusion, improving bind, color, and shelf-life while reducing additives.

- Throughput and flexibility: From pilot runs to industrial bowl chopper duty, capacities can align with 125–750 L-class needs to scale efficiently.

- Process control: Variable knife and bowl speeds, temperature monitoring, and recipe management drive consistent outcomes batch after batch.

- Footprint efficiency: A compact commercial bowl chopper integrates easily into existing lines and CIP or quick-clean routines.

Hebei Yuanchang’s engineering team supports application trials, line balancing, and custom options—such as a valve-integrated vacuum system or double bowl chopper layouts—to meet stringent B2B specifications. This expertise ensures your industrial meat bowl cutter investment aligns with QA, efficiency, and operator safety objectives.

Cost, Maintenance & User Experience

Total cost of ownership depends on uptime, energy draw, sanitation time, and consumables. Yuanchang’s Bowl Cutter solutions emphasize durable blades, balanced rotors, and sealed bearings to reduce vibrations and extend service intervals. Energy-efficient drives and vacuum optimization keep batch times short, which minimizes thermal rise and rework. The result is a favorable ROI driven by higher yields, fewer off-spec batches, and faster changeovers across recipes and SKUs.

Maintenance is straightforward: accessible knife hubs, smooth welds, and hygienic design support rapid washdowns, while optional tool-less guarding and interlocks simplify daily checks. Processors in the Special Equipment Manufacturing Industry consistently note improved texture consistency, quieter operation, and operator-friendly controls. Yuanchang’s parts availability and remote support further reduce downtime, making the equipment a reliable backbone for continuous or multi-shift operations that demand predictable output and compliance with rigorous plant standards.

Sustainability & Market Trends in manufacturing

Global trends point to automation, traceability, and clean-label formulations across food, beverage, tobacco, and feed. Efficient chopping and emulsification directly support these priorities by enabling tighter process control and reducing variability. Vacuum processing can lessen the need for stabilizers and color protectants, while precise cutting reduces waste and enhances yield. Sanitary design and optimized water use during cleaning contribute to resource efficiency—critical as regulations and stakeholder expectations rise around ESG performance.

Hebei Yuanchang Food Mechanism & Technology Co., Ltd. is investing in energy-efficient drives, smart controls, and robust stainless steel construction to extend service life and recyclability. By offering configurable vacuum bowl cutter and bowl cutter platforms that can integrate with line data systems, Yuanchang positions customers to meet evolving regulatory frameworks and quality systems. For manufacturers seeking scalable, eco-conscious technology, Yuanchang’s industrial bowl chopper portfolio aligns sustainability with measurable operational gains.

Conclusion on Bowl Cutter from Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

For B2B decision makers, a Bowl Cutter delivers consistent texture, higher yields, and accelerated batching—cornerstones of competitiveness in the Special Equipment Manufacturing Industry and the Manufacturing of specialized equipment for food, beverage, tobacco, and feed production. Hebei Yuanchang Food Mechanism & Technology Co., Ltd. backs every system with engineering expertise, robust fabrication, and responsive service. Whether you need a commercial bowl chopper for flexible production or a fully vacuum-enabled industrial solution, Yuanchang is a dependable partner. Contact us: email: ycmeatmech@gmail.com. Visit our website: https://www.ycmeatmech.com

-

Filling Flow Divider - Precision, Hygienic Multiline DosingNewsNov.18,2025

-

Hopper Trolley: Heavy-Duty, Ergonomic, Easy DischargeNewsNov.18,2025

-

Frozen Meat Slicer for Ultra-Thin, Precise, Safe CutsNewsNov.17,2025

-

Smoke House Machine | Precise, Energy-Efficient, HACCP-ReadyNewsNov.17,2025

-

Smoke House Machine: Uniform, Energy-Efficient SmokingNewsNov.11,2025

-

Meat Filling Machine - Stainless, Precise, High OutputNewsNov.11,2025