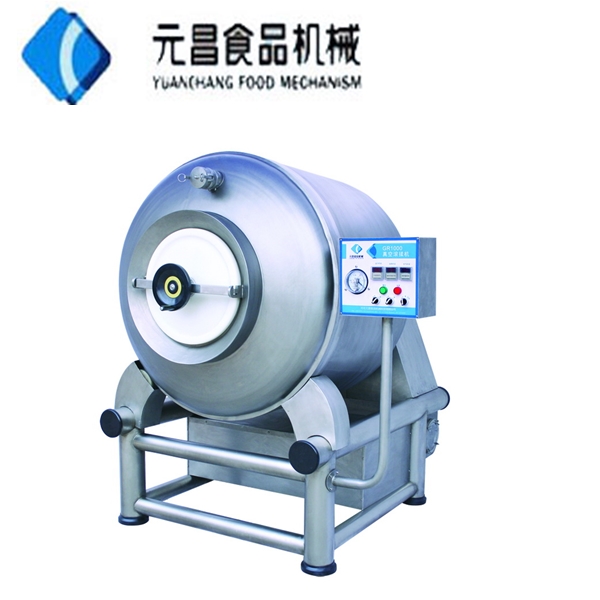

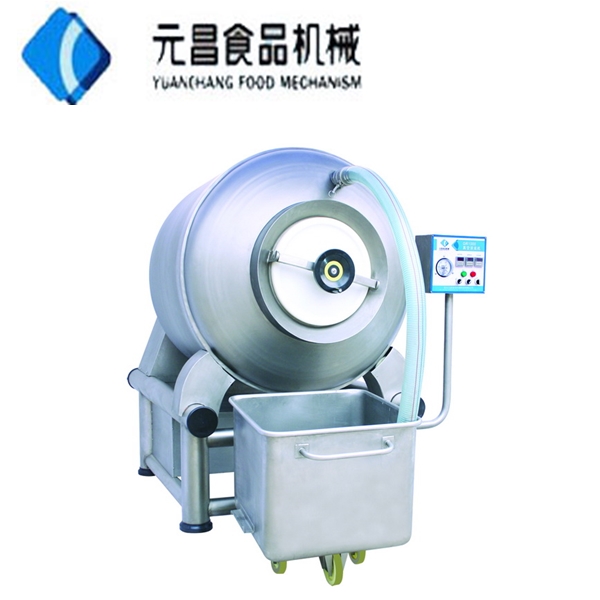

Vacuum Tumbler Marinator: Fast & Even Marinating

Transforming Food Processing: The Power of Vacuum Tumbler Technology

In the rapidly evolving landscape of food processing, efficiency, product quality, and consumer safety are paramount. The traditional methods of marinating and tenderizing meat, poultry, and seafood often prove time-consuming, inconsistent, and less effective in ensuring uniform flavor penetration and optimal texture. This challenge has driven innovation in food machinery, leading to the widespread adoption of advanced solutions like the vacuum tumbler marinator. This sophisticated equipment leverages vacuum technology and mechanical action to significantly enhance the marination process, offering unparalleled benefits in terms of yield, tenderness, and taste profile. It represents a critical investment for businesses aiming to streamline operations, reduce waste, and meet the growing demand for high-quality, ready-to-cook, or ready-to-eat protein products. The underlying principle involves creating a vacuum inside the tumbling drum, which opens up the muscle fibers of the product, allowing marinades to penetrate deeply and uniformly under controlled conditions, leading to superior product outcomes.

The global meat processing equipment market is experiencing robust growth, driven by increasing meat consumption, the demand for convenience foods, and stricter food safety regulations. Within this segment, vacuum tumblers are carving out a significant niche due to their proven ability to improve product quality and operational efficiency. Industry reports indicate a compound annual growth rate (CAGR) of over 5% for meat processing equipment, with vacuum marinating technology playing a crucial role in enhancing protein product value. This trend is fueled by processors seeking to reduce marination times, increase moisture retention, and achieve consistent product attributes across large batches. Furthermore, the emphasis on food hygiene and automation is pushing manufacturers to develop machines that are not only effective but also easy to clean and sanitize, adhering to stringent international standards like HACCP and FDA. This technological evolution enables food businesses to scale their production while maintaining superior quality, ultimately enhancing their competitive edge in a demanding market.

Mastering the Craft: Manufacturing Excellence of Vacuum Tumblers

The superior performance of a vacuum tumbler marinator begins with its meticulous manufacturing process and the selection of high-grade materials. At the core, these machines are constructed predominantly from food-grade stainless steel, primarily SUS304 or SUS316L, known for their exceptional corrosion resistance, durability, and hygienic properties. SUS304 is widely used for its general corrosion resistance, while SUS316L, with its added molybdenum content, offers enhanced resistance to pitting and crevice corrosion, making it ideal for highly corrosive environments or applications requiring stricter hygiene, such as those involving acidic marinades or seafood. The manufacturing journey typically involves several precision engineering stages: initially, large sheets of stainless steel are cut using advanced laser cutting technology to ensure precise component dimensions. These components then undergo expert forming, often through bending and rolling, to create the machine's drum, frame, and other structural elements. Critical joints are then meticulously welded using TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding techniques, ensuring strong, seamless, and hygienic connections that prevent bacterial traps.

Further enhancing durability and hygiene, key components like shafts, bearings, and critical moving parts are often subjected to CNC (Computer Numerical Control) machining. This allows for extremely tight tolerances and smooth finishes, reducing friction and wear, and facilitating easier cleaning. After fabrication, each component and the assembled machine undergo a rigorous multi-stage surface treatment, including pickling and passivation, to remove contaminants and enhance the steel’s inherent corrosion resistance. Finally, thorough polishing ensures an ultra-smooth surface, further inhibiting bacterial adhesion and simplifying sanitation—a crucial aspect for food safety. The entire manufacturing process adheres strictly to international quality management standards such as ISO 9001, ensuring consistent quality and reliability. Critical inspections are performed at every stage, from raw material verification to final assembly and performance testing. For instance, pressure testing of the vacuum chamber is critical to ensure it holds a consistent vacuum, while load testing verifies the machine's capacity and structural integrity under operational stress. The typical lifespan for a well-maintained meat tumbler machine manufactured under these stringent standards can exceed 10-15 years, providing long-term value in high-volume food processing environments.

Technical Specifications: Unpacking the Capabilities of Vacuum Meat Roller Tumbler Machine

Understanding the technical specifications of a vacuum tumbler machine is crucial for B2B decision-makers to select the right equipment for their operational needs. Key parameters define the machine's capacity, efficiency, and suitability for various applications. For instance, the drum capacity, typically measured in liters, dictates the maximum batch size that can be processed. Tumbling speed, measured in RPM, influences the mechanical action on the product, affecting tenderness and marinade absorption. The vacuum level, usually expressed in kPa or bar, is critical for opening muscle fibers and ensuring deep marinade penetration. Power consumption, measured in kW, provides insights into operational costs, while overall dimensions and weight are important for factory layout and installation. Our Vacuum Meat Roller Meat Tumbler Machine, designed for superior performance, exemplifies these critical specifications.

| Parameter | Metric/Value (Example) | Description & Importance |

|---|---|---|

| Drum Capacity | 100 L to 1500 L | Determines batch size; critical for matching production volume. For meat, typical fill rates are 60-70% of drum volume. |

| Vacuum Level | -0.08 to -0.09 MPa (-80 to -90 kPa) | Indicates the vacuum strength; higher vacuum allows for better fiber opening and marinade absorption. |

| Tumbling Speed | 4-12 RPM (variable) | Adjustable to suit different product types and desired mechanical action. Too fast can damage delicate products. |

| Motor Power | 1.5 kW to 7.5 kW (depending on size) | Influences energy consumption and the machine's ability to handle heavy loads consistently. |

| Material Construction | Food-grade SUS304 / SUS316L Stainless Steel | Ensures hygiene, durability, and corrosion resistance, crucial for food contact surfaces and compliance. |

| Control System | PLC with Touchscreen HMI | Offers precise control over parameters, programmability for different recipes, and ease of operation. |

| Dimensions (L x W x H) | Varies by model (e.g., 2000x1200x1800mm for 500L) | Important for facility layout, transportation, and installation planning. |

| Noise Level | Typically | Indicates operational acoustics, contributing to a comfortable working environment. |

Beyond these core specifications, advanced models may feature programmable logic controllers (PLCs) with touchscreen human-machine interfaces (HMIs) for precise control over tumbling cycles, vacuum levels, and rest periods, allowing for recipe management and consistency. Integrated chilling systems can maintain optimal product temperatures, crucial for food safety and preventing spoilage during processing. An effective marinating tumbler must also prioritize ease of cleaning, often incorporating smooth internal drum surfaces, accessible drain points, and quick-release components to facilitate thorough sanitation, meeting stringent food safety certifications like HACCP, CE, and sometimes NSF/ANSI 169 for special purpose food equipment. These certifications are not merely badges but demonstrate adherence to rigorous standards for design, material, construction, and performance, assuring buyers of the equipment's suitability for food contact and operation in hygienic environments.

Versatile Applications and Unparalleled Advantages

The application spectrum of a vacuum tumbler marinator extends across a diverse range of food processing sectors, from large-scale meat packers to poultry processing plants, seafood operations, and even emerging plant-based protein manufacturers. In the meat industry, it is indispensable for marinating beef, pork, and lamb cuts for steaks, roasts, and jerky, enhancing tenderness and flavor absorption. For poultry processors, it excels in preparing chicken parts, wings, and whole chickens for grilling, frying, or roasting, ensuring juicy, flavorful results and significantly increasing moisture retention, which directly translates to higher yields. Seafood processors utilize it for tenderizing octopus, marinating fish fillets, and preparing shrimp, improving texture and infusion of brines or sauces. Beyond traditional proteins, the technology is increasingly adopted in the production of vegan and vegetarian meat alternatives, where it helps in texturizing plant proteins and ensuring uniform absorption of flavors and colors.

The technical advantages offered by vacuum tumbler marinators are substantial and directly impact profitability and product quality. Firstly, the vacuum environment draws out air from the product, creating space for marinade to penetrate deeply and uniformly into muscle tissue, resulting in faster and more thorough marination compared to atmospheric methods. This can reduce marination times by up to 80%, significantly improving production throughput. Secondly, the gentle yet effective tumbling action mechanically tenderizes the product, breaking down connective tissues and enhancing protein extraction, which contributes to improved texture and bite. This also leads to increased yield through better moisture retention, with typical yield improvements ranging from 5% to 20% depending on the product and marinade. The controlled process also minimizes product damage, reducing drip loss and maintaining the integrity of delicate items. Furthermore, the hygienic, closed system of the vacuum tumbler reduces contamination risks, extending shelf life and ensuring consistent product quality, which is critical for brand reputation and consumer trust in competitive food markets.

Competitive Landscape: Choosing the Right Partner

In a market populated by numerous manufacturers, selecting the optimal vacuum tumbler marinator requires a critical evaluation of various factors beyond just the initial purchase price. Leading manufacturers differentiate themselves through innovative design, robust construction, advanced control systems, and comprehensive after-sales support. While some vendors may offer lower upfront costs, it’s imperative to assess the total cost of ownership (TCO), which includes energy consumption, maintenance, spare parts availability, and expected lifespan. Companies like ours, specializing in the Vacuum Meat Roller Meat Tumbler Machine, focus on delivering machines that not only perform exceptionally but are also built for longevity and operational efficiency. We emphasize high-grade stainless steel construction (SUS304 and SUS316L), precision-engineered components, and user-friendly PLC control systems that allow for precise process customization and recipe storage, ensuring consistent product quality batch after batch.

Our commitment to quality is underscored by our adherence to international manufacturing standards and rigorous testing protocols, ensuring that each chicken tumbler machine meets the highest benchmarks for hygiene and performance. Compared to generic alternatives, our machines often feature superior vacuum pump efficiency, more precise temperature control options, and intuitive interfaces that reduce operator training time and potential for error. We also pride ourselves on offering flexible customization options, allowing businesses to tailor the machine's capacity, features, and automation level to their specific production environment and product range. This bespoke approach ensures that clients receive a solution perfectly aligned with their operational objectives, whether it's maximizing yield, reducing processing time, or developing new product lines. Our long-standing presence in the industry and extensive service network underscore our authoritativeness and commitment to customer success.

| Feature | Our Vacuum Meat Roller Tumbler | Typical Competitor A | Typical Competitor B |

|---|---|---|---|

| Material Grade | SUS304/SUS316L (standard) | SUS304 (standard) | Mixed SUS304/Lower Grade |

| Control System | Siemens/Schneider PLC with HMI, Recipe Storage | Basic PLC with Buttons | Analog/Simple Digital |

| Vacuum Pump Type | High-efficiency, Oil-free (Optional) | Standard Oil-lubricated | Standard Oil-lubricated |

| Hygiene & Cleaning | Full Washdown Design, Smooth Interiors, Easy Access | Standard Food Grade, Some Hard-to-Reach Areas | Basic Food Grade |

| Energy Efficiency | Optimized Motor & Vacuum Pump | Standard Efficiency | Lower Efficiency |

| After-Sales Support | Global Service Network, Remote Support, Spare Parts Availability | Regional Support, Limited Spares | Minimal Support |

Beyond the Machine: Tailored Solutions and Unwavering Support

Recognizing that every food processing operation has unique requirements, our approach extends beyond merely supplying a standard vacuum tumbler marinator. We specialize in providing customized solutions that integrate seamlessly into existing production lines or are designed for new facility builds. This includes tailoring drum capacities to match specific throughput demands, implementing advanced automation features for reduced manual intervention, and incorporating specialized chilling or heating jackets for precise temperature control during processing. Whether a client requires a small-scale pilot machine for R&D or a large-volume industrial unit for continuous operation, our engineering team collaborates closely with them to assess their needs, conduct feasibility studies, and design a solution that optimizes their operational efficiency and product quality. This bespoke service ensures that our equipment not only fits physically within a plant but also functionally enhances the entire processing workflow, delivering tangible returns on investment.

Our commitment to customer success is further demonstrated through our robust support framework. From initial consultation and system design to manufacturing, installation, and after-sales service, we provide comprehensive assistance. Our standard delivery cycle typically ranges from 4-8 weeks, depending on customization levels and machine size, with clear communication throughout the process. Each machine comes with a standard 12-month warranty covering manufacturing defects and critical components, with extended warranty options available. Our dedicated customer support team and network of experienced technicians are available for troubleshooting, preventive maintenance, and supplying genuine spare parts quickly, minimizing downtime and ensuring continuous operation. This holistic approach, combined with our proven track record of delivering reliable and high-performance food processing equipment, builds trust and forms long-term partnerships with our clients globally. We are not just a supplier; we are a strategic partner in your success.

Frequently Asked Questions (FAQ)

- Q: What are the primary benefits of using a vacuum tumbler marinator over traditional marination methods?

- A: A vacuum tumbler offers significantly faster marination times (up to 80% reduction), deeper and more uniform marinade penetration, increased product yield due to enhanced moisture retention (typically 5-20% gain), improved tenderness, and consistent product quality across batches. The vacuum environment also enhances hygiene by reducing oxygen exposure.

- Q: What types of products can be processed in a Vacuum Meat Roller Meat Tumbler Machine?

- A: Our machines are highly versatile and can process a wide range of products including various cuts of beef, pork, and lamb, whole chicken and chicken parts, fish fillets, shrimp, octopus, and increasingly, plant-based protein alternatives and vegetables for marination or brining.

- Q: How do you ensure the hygiene and food safety of your vacuum tumblers?

- A: We use only food-grade stainless steel (SUS304/SUS316L) for all food-contact surfaces. Our machines feature a full washdown design with smooth, polished interiors to prevent bacterial traps and ensure easy, thorough cleaning. We adhere to international food safety standards such as HACCP, CE, and FDA guidelines in our manufacturing processes and design principles.

- Q: What is the typical lead time for delivery and installation of a new machine?

- A: Standard models typically have a lead time of 4-6 weeks from order confirmation to shipment. For highly customized machines, this can extend to 8-12 weeks. We provide clear communication regarding estimated delivery and can offer installation assistance or guidance upon arrival, depending on the client's needs and location.

- Q: What kind of after-sales support and warranty do you offer?

- A: We offer a standard 12-month warranty on our Vacuum Meat Roller Meat Tumbler Machine, covering manufacturing defects and key components. Our comprehensive after-sales support includes technical assistance, troubleshooting, remote diagnostics, and prompt availability of genuine spare parts to ensure minimal operational disruption. Extended warranty options and maintenance contracts are also available.

Conclusion: Driving Future Innovations in Food Processing

The demand for processed foods, particularly marinated and ready-to-cook protein products, continues its upward trajectory globally. This trend, coupled with increasing consumer awareness regarding food quality and safety, necessitates advanced processing solutions. The vacuum tumbler marinator stands out as an indispensable tool for modern food processors, offering a compelling blend of efficiency, product quality enhancement, and operational cost savings. Its ability to significantly reduce marination times, increase product yield, and ensure consistent flavor and texture across diverse product lines positions it as a cornerstone technology for competitive businesses. As the food industry continues to innovate, the evolution of vacuum tumbling technology will likely focus on greater automation, integration with AI for predictive maintenance, and further advancements in energy efficiency, making these machines even more vital for sustainable and profitable operations.

Our Vacuum Meat Roller Meat Tumbler Machine embodies the pinnacle of this technology, engineered to deliver consistent, high-quality results while adhering to the most stringent hygiene and safety standards. Through meticulous manufacturing, robust design, and a steadfast commitment to customer support, we empower businesses to optimize their production processes, expand their product offerings, and ultimately, enhance their market position. Investing in such a machine is not merely a purchase; it is a strategic decision that promises long-term benefits in terms of productivity, product excellence, and profitability. We invite you to explore how our tailored solutions can revolutionize your food processing operations.

References:

- Blesa, M. J., & Barrera, C. (2019). Meat processing and quality: The role of vacuum tumbling technology. Journal of Food Science and Technology.

- FAO. (2021). The State of World Fisheries and Aquaculture. Food and Agriculture Organization of the United Nations.

- USDA. (2020). Food Safety and Inspection Service Compliance Guidelines for Ready-To-Eat Meat and Poultry Products. United States Department of Agriculture.

- International Organization for Standardization (ISO). (2015). ISO 9001:2015 Quality management systems — Requirements.

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025

-

Best Commercial Marinating Machines for Meat Processing | Efficient & ScalableNewsNov.20,2025