Vacuum Tumbler Marinator: Faster, Juicier Meat - Why Wait?

Why processors are upgrading to a vacuum tumbler marinator in 2025

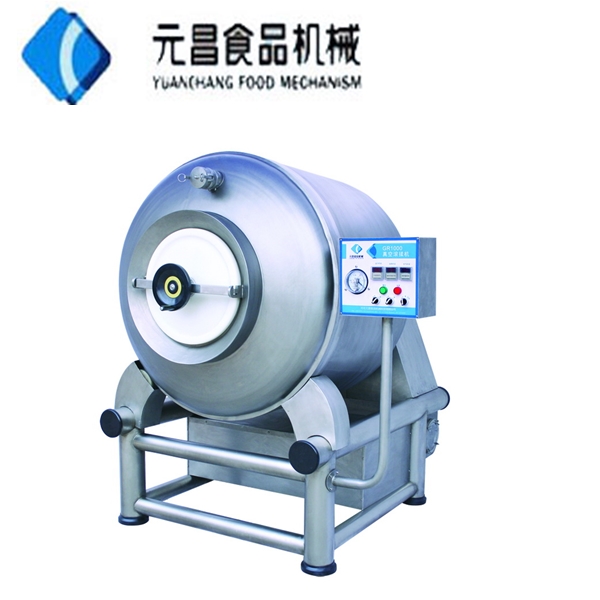

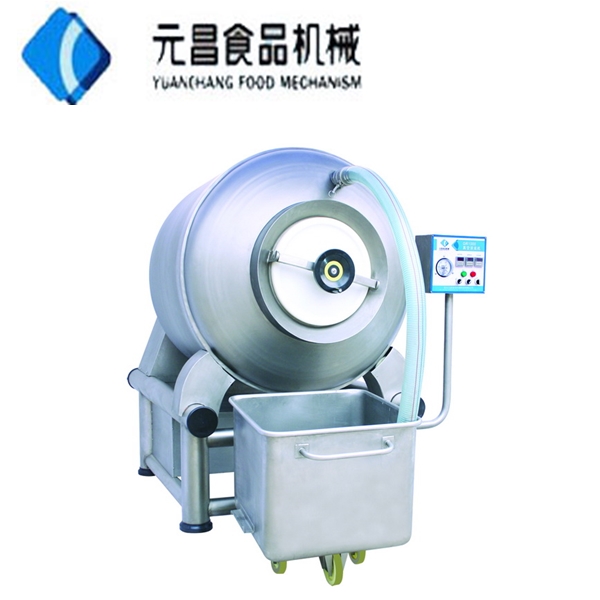

If you walk any modern meat plant floor, you’ll see the same story: shorter lead times, tighter brine specs, and QA teams auditing every data point. In that context, the YC Meat GR Series Vacuum Meat Roller Meat Tumbler Machine—built in Shijiazhuang, Hebei Province—has been getting real attention. To be honest, I didn’t expect tumbling to feel “new” again, but here we are.

What’s driving the trend

Processors want predictable uptake, faster protein extraction, and less purge in the bag. A vacuum tumbler marinator accelerates diffusion while protecting muscle integrity. Many customers say they cut marination windows by a third without losing yield—surprisingly consistent across poultry and pork.

Core specs (real-world ranges)

| Parameter | GR-600 | GR-1200 |

|---|---|---|

| Usable drum volume | ≈ 600 L | ≈ 1,200 L |

| Batch capacity (protein) | 250–400 kg | 500–800 kg |

| Vacuum level | up to −0.085 MPa | up to −0.09 MPa |

| Drum speed | 2–12 rpm (VFD) | 2–12 rpm (VFD) |

| Material | SUS304, bead-blast | SUS304, bead-blast |

| Seals/gaskets | Food-grade EPDM | Food-grade EPDM |

| Power | 3–5 kW, 380–480V | 5–7.5 kW, 380–480V |

| Service life (normal use) | ≈ 8–12 years | ≈ 8–12 years |

How plants actually run it

- Materials: trimmed poultry, pork, or beef; chilled brine 0–4°C.

- Method: load 40–60% drum fill, pull vacuum, tumble 2–12 rpm in intervals (e.g., 10 on/5 off).

- Testing: vacuum integrity by pressure decay; batch sampling per ISO 2859-1 AQL; salt and phosphate by titration; core temp probes.

- Targets: uptake +8–12%; purge reduction ≈ 0.4–0.8%; tenderness (shear) −10–20%.

- Industries: further-processing, smoked meats, QSR suppliers, ready-to-cook.

Advantages I keep seeing on-site

Faster diffusion under negative pressure, gentler massaging geometry, and fewer brine pockets. A vacuum tumbler marinator also evens out variability between lots—nice when raw material isn’t perfectly uniform.

Vendor snapshot (what buyers compare)

| Vendor | YC Meat (GR Series) | Regional OEM | Premium EU Brand |

|---|---|---|---|

| Origin | Shijiazhuang, China | APAC / Americas | EU |

| Lead time | ≈ 25–45 days | 30–60 days | 45–90 days |

| Certifications | CE, HACCP design notes | Varies | CE, EHEDG-inspired |

| Customization | High (ports, CIP, PLC) | Medium | Medium–High |

| Cost | $ (value) | $$ | $$$ |

| Warranty | 12–18 months | 12 months | 12–24 months |

Customization and controls

Options include programmable vacuum pulsing, saline-resistant seals, drum baffles, load cells, and CIP spray balls. Integrates with PLC/SCADA (Modbus/Profinet). For plants chasing audits, recipe lockout and batch reporting are worth it—actually saves arguments between QA and production.

Case study (condensed)

A mid-sized poultry processor swapped an older drum for the GR-1200. After two weeks: brine uptake +9.6% (avg), cook loss −0.7%, purge −0.5%, tenderness (Warner-Bratzler) improved 14%. Downtime fell ≈ 18% thanks to tool-less gasket change. As one supervisor put it, “It’s the first vacuum tumbler marinator that didn’t fight us on Monday mornings.”

Compliance, testing, and service life

- Food-contact metals: SUS304; seals meet food-grade requirements; documentation on request.

- Hygienic design: smooth welds, drainable orientations; CIP-ready configurations.

- QA: vacuum leak test (24 h, −0.085 MPa), electrical safety per CE; sampling by ISO 2859-1.

- Expected service life: ≈ 8–12 years; seals and bearings are usual wear parts.

Authoritative references

- ISO 22000:2018 Food Safety Management Systems – https://www.iso.org/standard/65464.html

- USDA FSIS: Appendix A – Compliance Guidelines for Lethality – https://www.fsis.usda.gov

- EHEDG Guidelines: Hygienic Equipment Design Principles – https://www.ehedg.org

- EU Machinery Directive 2006/42/EC (CE) – https://eur-lex.europa.eu

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025

-

Best Commercial Marinating Machines for Meat Processing | Efficient & ScalableNewsNov.20,2025