Vacuum Tumbler Marinator: Faster, Juicier, Higher Yield?

Vacuum Meat Roller Meat Tumbler Machine: field notes, specs, and what buyers really ask

I’ve walked a lot of plants where a single upgrade quietly changes everything. A vacuum tumbler marinator is one of those upgrades—less glamorous than a new smokehouse, perhaps, but it boosts yield, trims cycle time, and makes QC sleep easier at night.

Industry pulse

Big processors already know: vacuum tumbling is mainstream for poultry portions, pork primals, and even plant-based proteins. What’s new is smarter controls, better hygienic design, and data logging that auditors actually accept. To be honest, the trend I see most is shorter marination windows—retail wants agility—so equipment that hits -0.08 MPa fast and holds it steady wins the day.

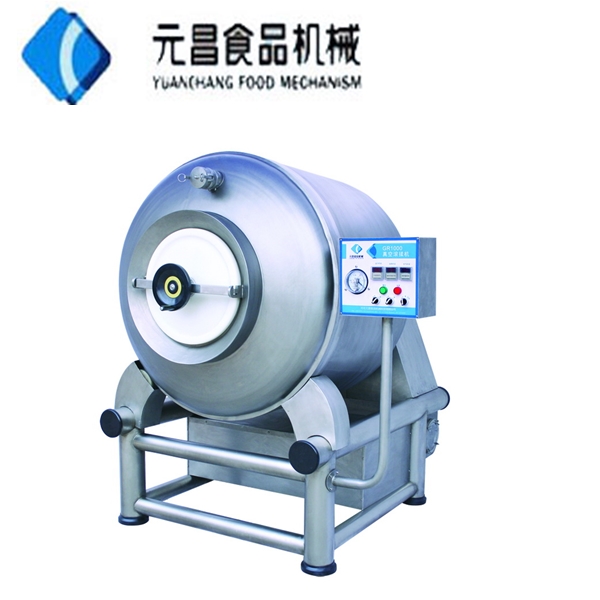

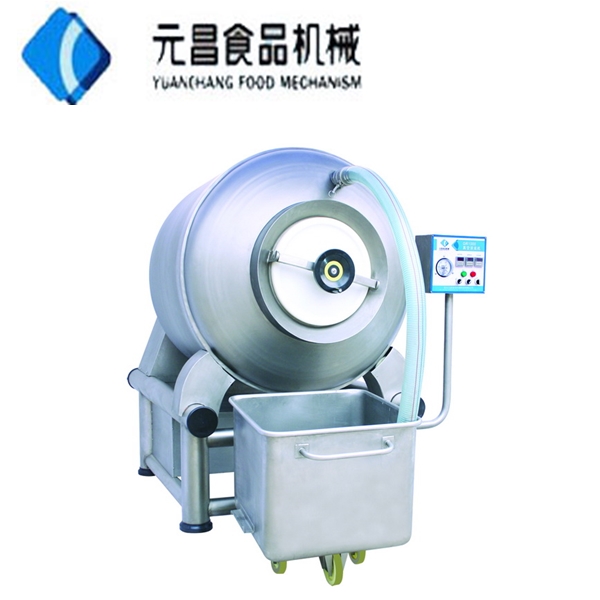

YC Meat GR Series at a glance

Built in Shijiazhuang, Hebei Province, China, YC Meat’s GR Series is stainless-steel through and through, aimed at large meat and poultry processors. It’s pragmatic, not flashy, which I like. Many customers say the HMI is simple enough that the night shift won’t call engineering at 2 a.m.

| Spec | GR Series (≈ real-world) |

|---|---|

| Usable drum volume | ≈ 300–5,000 L (load 40–50%) |

| Material | SUS304 (option SUS316L); Ra ≤ 0.8 μm |

| Vacuum level | Up to −0.085 MPa; hold drop ≤ 1 kPa/5 min |

| Tumble speed | 4–12 rpm, VFD controlled |

| Controls | PLC + 7–10" HMI, recipes, data log |

| Utilities | 3–11 kW drive; optional chilled jacket |

| Hygiene | CIP spray balls, slope-to-drain, clean welds |

| Service life | ≈ 8–12 years with PM |

Process flow (how plants actually run it)

- Materials: poultry pieces, pork muscles, beef steaks; brines with salt, phosphates (where legal), spices, functional proteins.

- Method: load 40–50% volume → draw vacuum to −0.08 MPa → tumble 20–90 min at 6–10 rpm (program pulses) → rest/soak as needed → discharge.

- Testing: marinade pickup %; cook loss; Warner–Bratzler shear for tenderness; vacuum hold test; ATP swabs post-CIP.

- Standards: HACCP/ISO 22000; food-contact per ASTM A240 (steel) and EU 1935/2004; hygienic design referencing EHEDG/3-A.

- Typical results: +2–8% yield, −1–3% cook loss, tighter SD on salt pickup. Your mileage may vary, of course.

- Industries: retail ready-to-cook, QSR commissaries, export plants, seafood lines, and a growing plant-based crowd.

Why a vacuum tumbler marinator pays for itself

Faster diffusion under vacuum means shorter cycles and better brine distribution. Operators like the predictable texture; finance likes the yield. Noise is reasonable, and—surprisingly—the cleaning time is often the bottleneck, not tumbling. CIP helps.

| Vendor (indicative) | Volume range | Vacuum | Controls | Certs | Lead time |

|---|---|---|---|---|---|

| YC Meat (GR Series) | 300–5,000 L | Up to −0.085 MPa | PLC/HMI, recipes, log | CE, ISO 9001 | around 4–8 weeks |

| Typical EU premium brand | 200–6,000 L | Up to −0.090 MPa | Advanced PLC, IoT | CE, EHEDG | 8–16 weeks |

| Typical US mid‑market brand | 300–3,000 L | Up to −0.080 MPa | PLC/HMI | UL/ETL, USDA‑ready | 6–12 weeks |

Customization options

Paddle geometry for delicate fillets, SUS316L for briny seafood, jacketed cooling, load cells, different PLC brands, voltage choices, extra CIP balls. Small tweaks matter. It seems that recipe-based ramping of vacuum and speed is where teams get the biggest gains with a vacuum tumbler marinator.

Case note (Hebei poultry processor)

Three weeks after installing the GR Series, a plant running 2.2‑kg poultry portions reported marinade pickup rising from 8.5% to 12.1% (n=12 batches), cook loss −1.7 points, and cycle time down 30%. Yield up ≈4% overall; payback ~6 months. Operators called out the quieter drive and simpler CIP screens—small wins, sure, but they add up with a vacuum tumbler marinator.

Compliance, testing, and documentation

- Materials traceability to ASTM A240; gaskets/hoses with food-contact declarations (EU 1935/2004, where applicable).

- HACCP/ISO 22000 alignment; sanitation design referencing EHEDG/3‑A guidelines.

- Factory tests: vacuum hold, noise ≤ 75 dB(A), weld passivation, and CIP coverage checks (dye/visual).

References

- ISO 22000:2018 Food safety management systems.

- ASTM A240/A240M – Standard Specification for Chromium and Chromium‑Nickel Stainless Steel Plate, Sheet, and Strip.

- EHEDG Guidelines on Hygienic Equipment Design (Doc 8 and related).

- EU Regulation No 1935/2004 on materials intended to come into contact with food.

- AMSA (American Meat Science Association) tenderness and marination best practices.

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025

-

Best Commercial Marinating Machines for Meat Processing | Efficient & ScalableNewsNov.20,2025