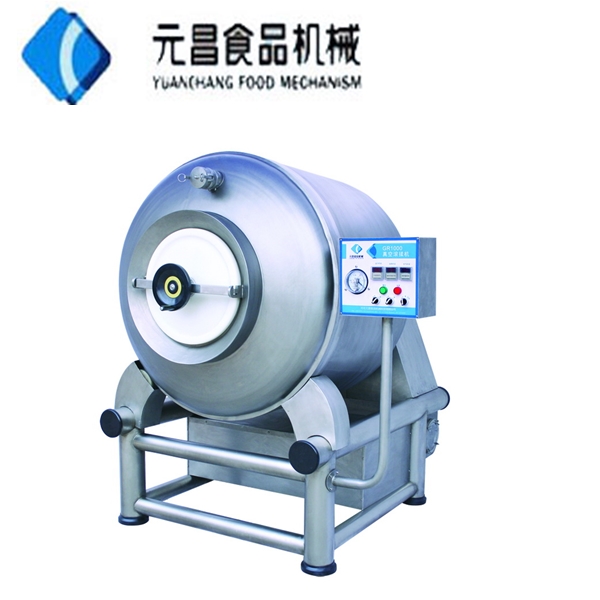

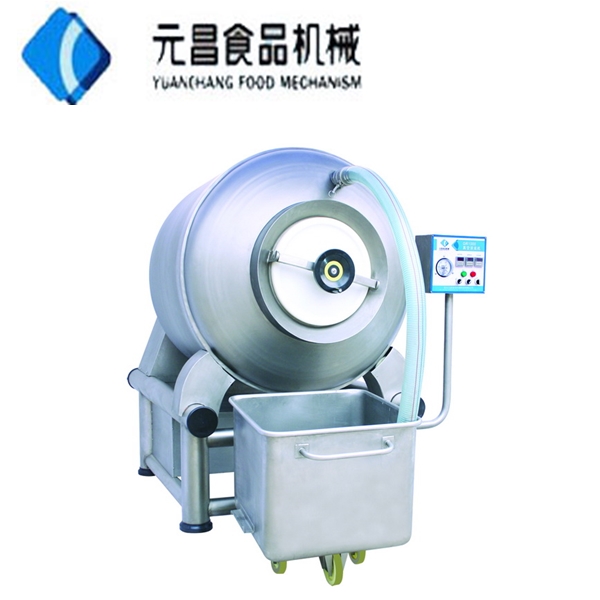

Vacuum Tumbler Marinator: Faster, Juicier, Even Flavor

Vacuum Meat Roller Meat Tumbler Machine: what processors really ask me on the plant floor

If you’re sizing up a vacuum tumbler marinator for serious throughput, you’re not alone. From Shijiazhuang, Hebei, the YC Meat GR Series has been cropping up in mid/large plants I visit. Stainless build, industrial duty, practical price—actually a sensible combo. And yes, it’s designed for big meat and poultry processors, though seafood and alt-protein teams keep kicking its tires, too.

What’s changing in the market

Trend-wise: processors want tighter yield control, shorter marination cycles, and repeatable tenderness without babysitting the line. Energy use matters more than it did three years ago. Also, retailers are pushing clean labels, so the tumbling step has to do more work with fewer phosphates. Many customers say a well-tuned vacuum tumbler marinator buys them 3–5% yield and better brine pickup—if the vacuum is stable and the drum geometry is right.

Typical process flow (real-world)

- Materials: chilled meat/poultry blocks, standardized brine; SUS304 contact surfaces (316L optional).

- Method: load → seal → evacuate to ≈ −0.08~−0.09 MPa → tumble 3–12 rpm (VFD) with intermittent rest → hold/age.

- Controls: PLC/HMI recipes, temp monitor; optional jacket for cooling.

- Testing standards: HACCP verification (salinity, pH), pickup %, cook yield, shear force, Lab color uniformity.

- Service life: around 10–15 years with preventive maintenance; seals/bearings are the usual wear parts.

- Industries: meat, poultry, seafood, plant-based protein, ready-to-eat items.

YC Meat GR Series — key specs (typical)

| Parameter | GR-1000 | GR-1500 | Notes |

|---|---|---|---|

| Drum volume | ≈1000 L | ≈1500 L | Real-world usable fill ≈ 40–60% |

| Batch capacity | 400–700 kg | 600–1000 kg | Product-dependent |

| Vacuum level | −0.08~−0.09 MPa | −0.08~−0.09 MPa | Stable hold is critical |

| Speed | 3–12 rpm (VFD) | 3–12 rpm (VFD) | Programmable |

| Power | ≈4–6 kW | ≈6–9 kW | Energy use varies |

| Material | SUS304 | SUS304/316L | Food-contact finishes |

| Controls | PLC + HMI | PLC + HMI | Recipe memory |

| Certs | CE, ISO 9001 | CE, ISO 9001 | HACCP-ready design |

| Origin | Shijiazhuang, Hebei | Shijiazhuang, Hebei | China |

Applications, advantages, quirks

Where it shines: bone-in poultry (gentle action), pork loins, beef trims, seafood fillets, and yes, plant-based chunks that need functional brine uptake without crumbling. Advantages include faster brine diffusion under vacuum, protein extraction for better bind, and more uniform color. Surprisingly, a well-set vacuum tumbler marinator can cut cycle time by 20–30% vs. atmospheric tumbling. Quirk: don’t overfill; headspace helps brine distribute.

Vendor comparison (snapshot)

| Criteria | YC Meat GR Series | EU Premium Brand | Entry-Level Import |

|---|---|---|---|

| Price level | Mid | High | Low |

| Lead time | ≈4–8 weeks | ≈10–16 weeks | ≈6–10 weeks |

| Customization | High (drum, fins, PLC) | Medium–High | Low |

| Vacuum stability | Stable −0.08~−0.09 MPa | Excellent | Variable |

| Certifications | CE, ISO 9001 | CE, UL options | Basic/varies |

| After-sales | Remote + spares, pragmatic | Global network | Limited |

Customization and validation

Options I’ve seen: 316L contact parts, CIP spray balls, jacketed cooling, load cells for inline pickup %, and guarded doors that satisfy the Machinery Directive. Plants usually validate with side-by-side runs: measure marinade pickup, cook yield, shear force (Warner–Bratzler), and purge after 48 h. One poultry team told me the vacuum tumbler marinator cut purge by ~0.6%—modest but meaningful at scale.

Mini case notes

- Boneless skinless chicken: 12–18% pickup, +3–5% cooked yield, shear force 10–15% vs. control; 35 min cycle under −0.09 MPa. Results may vary.

- Pork loin portioning: 8–12% pickup with low-phosphate brine; color ΔE improved by ~20% uniformity. QA signed off after 3 consecutive lots.

Compliance checklist

Look for CE marking, ISO 9001 quality systems, HACCP-aligned hygienic design, and food-contact compliance per EU 1935/2004 or equivalent. Some buyers also reference ISO 22000 and EHEDG/3-A style sanitation principles. To be honest, documentation matters as much as welds when auditors show up.

Bottom line

If you need dependable yields without a boutique price, the GR Series is worth a demo. It’s the kind of kit that rewards disciplined recipes and sensible fill ratios. And if you’re migrating from batch inject-and-rest, a robust vacuum tumbler marinator can make your QA graphs a little less spiky.

Authoritative citations

- Codex Alimentarius, General Principles of Food Hygiene (HACCP), CAC/RCP 1-1969 (Rev.).

- EU Regulation (EC) No 1935/2004 on materials intended to come into contact with food.

- EU Machinery Directive 2006/42/EC.

- ISO 22000:2018 Food safety management systems — Requirements for any organization in the food chain.

- Meat Science journal reviews on vacuum tumbling and marination performance (representative literature).

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025

-

Best Commercial Marinating Machines for Meat Processing | Efficient & ScalableNewsNov.20,2025