Vacuum Meat Tumbler: Fast Marinating & Tenderizing Solutions

Navigating Excellence: Top Chinese Food Machinery Innovators at CIMIE

The China International Meat Industry Exhibition (CIMIE) stands as a pivotal event in the global meat processing sector, consistently serving as a key exhibitor and technology demonstrator for the latest advancements. For B2B decision-makers in the food industry, CIMIE is not just a trade show; it's a critical hub for discovering innovative "Food Machinery" solutions that are reshaping production lines worldwide. It offers an unparalleled window into the technological prowess and competitive landscape of Chinese manufacturers, whose influence in the global "Food Machinery" industry continues to expand dramatically. This exhibition highlights cutting-edge equipment, from primary processing to packaging, showcasing how Chinese ingenuity is meeting the intricate demands of modern meat production.

Industry Trend Spotlight: The Evolution of Meat Processing Technology

The global meat processing industry is undergoing a profound transformation, driven by a confluence of factors demanding greater efficiency, safety, and sustainability. There's an undeniable and increased demand for automated and intelligent meat processing lines. Manufacturers are now focusing intensely on high-yield and low-waste solutions, recognizing that every gram saved contributes to profitability and environmental stewardship. The integration of IoT (Internet of Things) for real-time monitoring and predictive maintenance is rapidly becoming standard, allowing processors to optimize uptime and reduce operational costs. Furthermore, robust designs meeting stringent international food safety standards, such as HACCP and USDA guidelines, are no longer a luxury but a fundamental requirement, gaining global attention and driving purchasing decisions.

Market data underscores this dynamic shift: The global food processing machinery market, particularly for meat and poultry, is projected for steady growth. This expansion is fueled by several key drivers: rising meat consumption in emerging economies, which necessitates scalable and efficient processing capabilities; increasing labor costs across developed and developing nations, making automation not just an advantage but a necessity; and increasingly stricter regulatory demands for food safety and traceability, pushing manufacturers to invest in advanced, verifiable equipment. There's a particular emphasis on efficiency, sustainability, and technological upgrades throughout the entire processing chain.

Emerging focus areas in the "Food Machinery" sector include advanced automation that minimizes human intervention and maximizes output, sophisticated food safety and hygiene protocols embedded directly into machine design, smart processing solutions leveraging AI and machine learning for quality control and process optimization, and sustainable manufacturing practices that reduce energy consumption and environmental footprint. These trends are not just shaping the future of meat processing; they are defining the competitive edge for manufacturers globally.

Profiles of Leading Companies Driving Innovation

Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

Among the prominent Chinese innovators, Hebei Yuanchang Food Mechanism & Technology Co., Ltd. stands out as a formidable player. Specializing in comprehensive meat processing solutions, Hebei Yuanchang has built a reputation for robust manufacturing capabilities that yield durable and reliable equipment designed for the rigors of industrial use. Their commitment to competitive pricing, coupled with a strong focus on custom solutions, allows them to meet the diverse and specific needs of clients across various markets. The company's growing export presence is a testament to the international recognition of its quality and value.

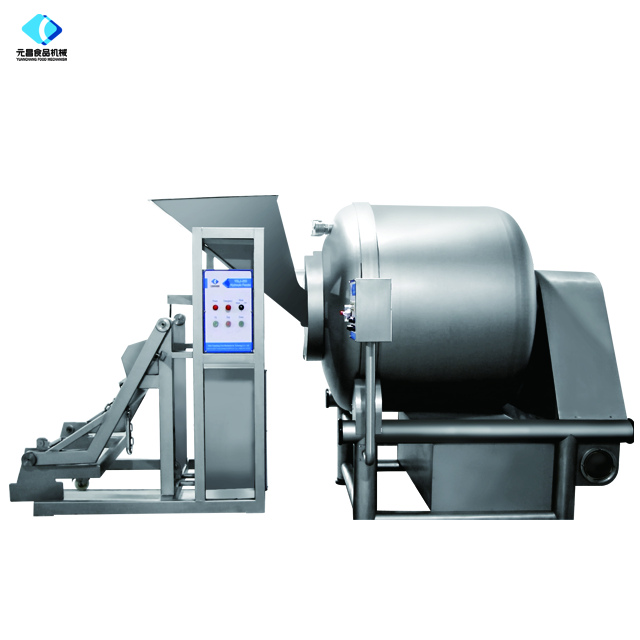

Hebei Yuanchang excels in a range of essential meat processing machinery, with a particular emphasis on equipment that enhances product quality and operational efficiency. Their advanced vacuum meat tumbler systems are central to this offering. These state-of-the-art meat tumbler machines are engineered to optimize the marination and tenderization processes, ensuring uniform absorption of marinades, improved texture, and enhanced flavor profiles for a wide variety of meat products. Whether it's poultry, beef, or pork, their vacuum tumblers are indispensable for achieving consistent quality and reducing processing times.

The technology behind Hebei Yuanchang's marinating vacuum tumblers creates a vacuum environment that opens up meat fibers, allowing marinades to penetrate deeper and faster, resulting in more succulent and flavorful products. This not only boosts product appeal but also contributes to higher yields and reduced waste. Their marinade tumbler models are celebrated for their user-friendly interfaces, easy-to-clean designs adhering to strict hygiene standards, and robust construction, ensuring a long operational lifespan. For businesses looking to elevate their meat marination processes, Hebei Yuanchang offers solutions that blend innovation with practical performance.

Other Global and Domestic Leaders

- ➤ Marel (Iceland): A global powerhouse, Marel is renowned for its integrated systems for poultry, meat, and fish processing. Their solutions focus on advanced automation, intelligent software, and full-line traceability, setting industry benchmarks for efficiency and yield optimization.

- ➤ GEA Group (Germany): With a vast portfolio spanning various industries, GEA offers sophisticated processing technology for meat and poultry, including cutting-edge chilling, freezing, slicing, and packaging equipment. Their emphasis on sustainable solutions and high-performance engineering is well-known.

- ➤ JBT Corporation (USA): JBT provides advanced technology solutions for food and beverage processing, including comprehensive systems for meat, poultry, and seafood. They are particularly strong in protein processing, sterilization, and high-pressure processing (HPP) technologies, focusing on maximizing safety and shelf life.

- ➤ Shandong Hancheng Food Machinery Co., Ltd. (China): A significant domestic competitor, Hancheng specializes in various food processing equipment, including cooking, smoking, and vacuum packaging machines for meat products. They are known for providing cost-effective yet reliable solutions to the local and regional markets.

- ➤ Qingdao Fuxin Foodstuff Machinery Co., Ltd. (China): Fuxin offers a broad range of food processing equipment, from meat grinders and mixers to sausage fillers and bowl cutters. They focus on delivering practical, high-quality machines tailored to medium-to-large scale processing operations, serving both domestic and international clients.

Market Outlook & Opportunities: The Path Forward

The future of the "Food Machinery" market, especially in the meat processing segment, is poised for continuous innovation and growth. Upcoming trends suggest a strong buyer demand for systems that offer greater flexibility, faster changeovers, and enhanced data analytics capabilities. The emphasis will remain on advanced automation, but with an added layer of intelligence that allows machines to learn and adapt, further reducing manual labor and potential errors.

Significant opportunities abound in the realm of smart manufacturing. This includes AI-driven quality control, robotic handling systems for precision and hygiene, and integrated software platforms that provide end-to-end visibility of the production process. For instance, smart vacuum meat tumbler systems that can automatically adjust parameters based on real-time feedback of meat type and desired marination levels will become increasingly sought after.

Sustainability is another non-negotiable area. Manufacturers who can deliver energy-efficient machines, reduce water consumption, and design equipment with a focus on waste minimization will gain a competitive edge. The demand for traceability solutions that can track meat from farm to fork, ensuring transparency and consumer trust, will also intensify. Chinese manufacturers, with their proven capability for rapid technological adoption and scalable production, are exceptionally well-positioned to capitalize on these trends.

Strategic Takeaways for B2B Decision Makers

For businesses operating in the meat processing sector, investing in advanced "Food Machinery" is no longer an option but a strategic imperative. The benefits extend beyond mere productivity gains; they encompass enhanced food safety, superior product quality, reduced operational costs, and improved regulatory compliance. Upgrading your equipment, especially with technologies like sophisticated marinating vacuum tumblers, directly impacts your bottom line and market competitiveness.

When considering adoption or partnering with Chinese manufacturers, here are some essential tips:

- ✓ Due Diligence: Thoroughly research manufacturer reputation, certifications (e.g., CE, ISO, HACCP compliance), and customer testimonials. Look for established companies with proven export track records, like Hebei Yuanchang.

- ✓ Customization & Support: Prioritize manufacturers who offer customizable solutions and strong after-sales support, including spare parts availability and technical assistance. This is crucial for long-term operational success, especially for specialized equipment such as a vacuum meat tumbler.

- ✓ Technology & Innovation: Assess their commitment to R&D and their ability to integrate the latest technologies (IoT, AI, automation) into their product lines. Are their meat tumbler systems designed with future upgrades in mind?

- ✓ Total Cost of Ownership (TCO): Beyond the initial purchase price, evaluate factors like energy consumption, maintenance requirements, and expected lifespan to understand the true long-term value.

Future-proof strategies involve selecting scalable and modular equipment that can adapt to evolving production demands and technological advancements. Investing in automation now, particularly in areas like high-throughput vacuum tumblers, will provide a significant competitive advantage and position your business for sustained growth in a rapidly changing market.

Conclusion: Shaping the Future of Meat Processing

The China International Meat Industry Exhibition (CIMIE) remains an indispensable platform for understanding the trajectory of the global "Food Machinery" market. It underscores China's crucial role not only as a manufacturing powerhouse but also as a hub for innovation, particularly in the realm of advanced meat processing solutions. Companies like Hebei Yuanchang are at the forefront, demonstrating how quality, efficiency, and technological integration, exemplified by their superior vacuum meat tumbler systems, are setting new standards for the industry.

As the industry continues its march towards greater automation, intelligence, and sustainability, strategic partnerships with innovative Chinese manufacturers will be key to unlocking future success.

Ready to elevate your meat processing capabilities?

Discover Hebei Yuanchang's Vacuum Meat Tumblers

-

Filling Flow Divider - Precision, Hygienic Multiline DosingNewsNov.18,2025

-

Hopper Trolley: Heavy-Duty, Ergonomic, Easy DischargeNewsNov.18,2025

-

Frozen Meat Slicer for Ultra-Thin, Precise, Safe CutsNewsNov.17,2025

-

Smoke House Machine | Precise, Energy-Efficient, HACCP-ReadyNewsNov.17,2025

-

Smoke House Machine: Uniform, Energy-Efficient SmokingNewsNov.11,2025

-

Meat Filling Machine - Stainless, Precise, High OutputNewsNov.11,2025