Meat Dicer Machine for Sale: Fast, Precise, Easy-Clean?

Insider’s Guide: Choosing a Meat Diced Machine (and spotting a real meat dicer machine for sale that’s worth it)

If you’ve been hunting for a meat dicer machine for sale, you’ve probably noticed two things: specs can be vague, and prices jump wildly. I’ve toured plants in Shijiazhuang and Qingdao over the years and, to be honest, the best machines share the same DNA—food-grade steel, stable drive systems, and blades that stay sharp longer than you expect. The Meat Diced Machine from Hebei (yes, that one) has been making the rounds lately, and for good reason.

What’s trending in protein processing

Three trends keep coming up in real factory conversations: higher throughput for frozen blocks, easier sanitation (fewer harborage points), and traceable cuts for QC. Actually, many customers say they want one machine that can dice, slice, and strip cut without a whole afternoon lost to changeovers. The Hebei-origin unit checks those boxes, with tooling that switches in minutes.

Quick look: Product specs (real-world ranges)

| Parameter | Typical Range / Notes |

|---|---|

| Dice size | ≈ 3–30 mm (tooling dependent; real-world use may vary) |

| Throughput | around 500–2,000 kg/h, depending on meat temperature and cut |

| Meat types | Frozen, cooked, poultry; capable of bone-in trimming cuts |

| Build material | SUS304 contact surfaces; optional SUS316 for brine-heavy lines |

| Power / Voltage | ≈ 3–7.5 kW; 380–415V 50Hz (other voltages on request) |

| Noise | ≈ 75–82 dB(A) under load (environment dependent) |

| FOB / MOQ / Supply | FOB US $0.5–9,999 per piece; MOQ ~100; supply ≈10,000 pcs/month |

How it fits into your line (materials → methods → testing)

- Materials in: frozen blocks (-4°C to -12°C), chilled primals, cooked logs.

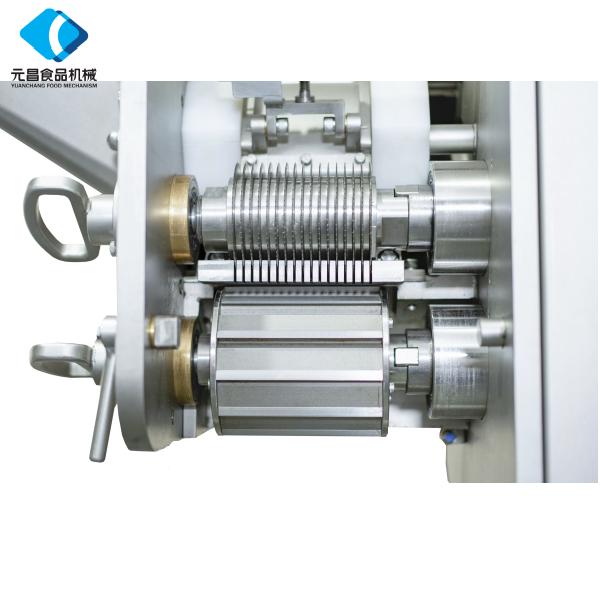

- Methods: rotary blade + grid set; quick-change knife cassettes; adjustable feed pressure to keep geometry consistent.

- Sanitation: tool-less panels, sloped surfaces, CIP-friendly guards; food-grade seals.

- Testing standards: vendors commonly reference ISO 14159 hygiene design and EN 1672-2; QA teams verify swab hygiene and guarding against pinch points.

- Service life: blades typically re-honed on a 2–6 month cycle; main bearings designed for multi-year duty with proper lubrication (actual life varies).

- Industries: ready-meal plants, QSR suppliers, airline catering, pet food, smallgoods.

Where it shines in the real world

Application scenarios I see most: frozen beef cubes for stews, diced ham for pizzas, poultry for salad kits, and—surprisingly—pet-food chunks where consistency matters to downstream fillers. Feedback I keep hearing: high working efficiency, steady cube geometry, and fewer operator tweaks during long runs.

Advantages worth noting: robust drive train, sensible safety interlocks, and blades that don’t chip when a small bone sneaks in. It seems that maintenance teams like the clearances—no goofy tools required.

Vendor comparison (snapshot)

| Vendor | Origin | Certifications (typical) | MOQ | Lead Time | After-Sales |

|---|---|---|---|---|---|

| Meat Diced Machine (Hebei) | Shijiazhuang, China | CE declaration; ISO 9001; food-contact materials per ISO 14159 (verify) | ≈100 | around 20–35 days | Remote commissioning + parts kits |

| Alt Vendor A | Guangzhou, China | CE; ISO 9001 (public listings) | 50–100 | 30–45 days | Standard warranty; paid on-site |

| Alt Vendor B | EU assembly | CE; EHEDG design claims (check docs) | 1–5 | 45–90 days | On-site + validation options |

Note: certifications and lead times should be verified against current vendor documentation.

Customization and mini case notes

Custom options I’ve seen: 316L upgrade for brine-heavy ham, variable grid sets for 6/8/10 mm cubes, low-temp kits for deep-frozen blocks, and guard sensors tied into plant PLCs. One bakery-meats line used the meat dicer machine for sale to switch between 8 mm ham and 12 mm chicken with a sub-10-minute changeover—operators were, frankly, relieved.

Another pet-food processor ran a week-long trial—output stayed within target cube variance, and cleaning time dropped because the panels actually come off without a wrestling match. Small detail, big morale boost.

Compliance checklist (ask your QA)

- Hygienic design per ISO 14159 and EN 1672-2.

- Food safety programs aligned with HACCP / ISO 22000.

- If exporting to the U.S., check 21 CFR Part 117 (cGMP) alignment.

- Electrical safety and guarding documentation; risk assessment file available.

Bottom line: if you need a robust, efficient meat dicer machine for sale with sane maintenance, the Hebei-built unit is a smart shortlist pick. Pricing spans widely (FOB US $0.5–9,999), so spec your dice sizes, throughput, and sanitation needs before negotiating.

Authoritative sources

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025

-

Best Commercial Marinating Machines for Meat Processing | Efficient & ScalableNewsNov.20,2025