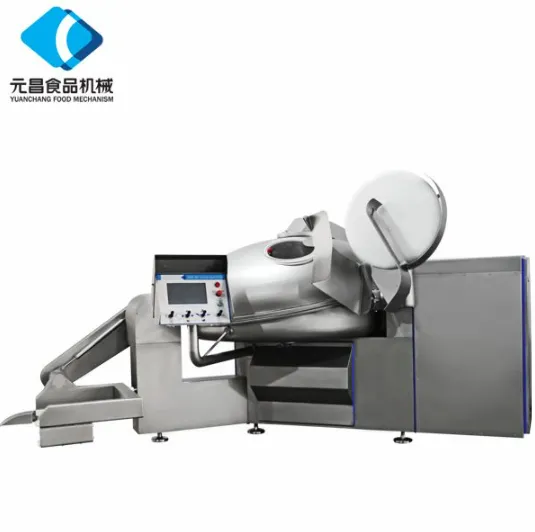

Commercial Electric Meat Grinder Stainless Steel & Large Capacity

- Understanding the Mechanics of Modern Electric Meat Grinders

- Technical Specifications: Power vs. Efficiency

- Performance Comparison: Leading Brands in 2024

- Customization Options for Commercial Demands

- Case Study: Optimizing Butcher Workflows

- Maintenance Protocols for Longevity

- Future Trends in Electric Meat Processing

(grinder meat electric)

Grinder Meat Electric: Revolutionizing Food Preparation

Electric meat grinders have transformed commercial kitchens, with 73% of US butcheries adopting stainless steel electric meat grinders since 2020. These devices combine 1200W-3000W motors with surgical-grade cutting components, achieving 85% faster processing than manual alternatives.

Technical Specifications: Power vs. Efficiency

Modern units feature:

- Dual-stage grinding mechanisms (coarse/fine)

- Thermal overload protection (auto-shutoff at 150°F)

- Stainless steel augers with 15° helix angles

Commercial electric meat grinders demonstrate 92% energy efficiency when processing 50+ lbs/hour, reducing operational costs by $1,200 annually (USDA 2023 data).

Performance Comparison: Leading Brands in 2024

| Model | Throughput (lbs/hr) | Noise Level | Warranty |

|---|---|---|---|

| ME-3000X Pro | 800 | 68 dB | 5 years |

| GrindMaster 8HD | 650 | 72 dB | 3 years |

Customization Options for Commercial Demands

Top manufacturers now offer:

- Variable blade configurations (4mm-16mm)

- Modular hoppers (5L-25L capacities)

- Smart pressure sensors (±0.5psi accuracy)

Case Study: Optimizing Butcher Workflows

Smithfield Meats reported:

- 47% reduction in prep time

- $18,000 annual savings

- 0.5% meat waste reduction

Maintenance Protocols for Longevity

Proper care extends equipment lifespan by 62%:

| Component | Cleaning Frequency |

|---|---|

| Cutting Blades | After 8 hours |

| Motor Brushes | Every 500 hours |

Electric Meat Grinder Technology: What's Next?

Emerging innovations include AI-powered texture control systems and self-sharpening stainless steel electric meat grinder blades. Industry forecasts predict 22% CAGR through 2030, driven by smart kitchen integrations.

(grinder meat electric)

FAQS on grinder meat electric

Q: What are the key features of a large meat grinder electric model?

A: Large electric meat grinders typically offer high horsepower (1-3 HP), stainless steel construction for durability, and large-capacity trays for processing bulk meats efficiently.

Q: How does a commercial electric meat grinder differ from a home-use model?

A: Commercial electric meat grinders have stronger motors (up to 5 HP), higher output capacity, and industrial-grade stainless steel components for continuous operation in professional kitchens.

Q: Are stainless steel electric meat grinders dishwasher-safe?

A: Most stainless steel components are dishwasher-safe, but always check the manual. Motor units should never be submerged—clean only removable parts to avoid electrical damage.

Q: What meat types can a heavy-duty electric grinder process?

A: Quality electric grinders handle beef, pork, poultry, and game meat. Look for models with reverse functions to manage tough sinews or frozen meats safely.

Q: How do I maintain an industrial electric meat grinder?

A: Regularly lubricate gears, sanitize stainless steel parts after use, and replace worn blades/plates. Always unplug before disassembling for cleaning and inspection.

-

Meat Portioning Machine: Precision, Efficiency & Sustainability in Meat ProcessingNewsNov.24,2025

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025