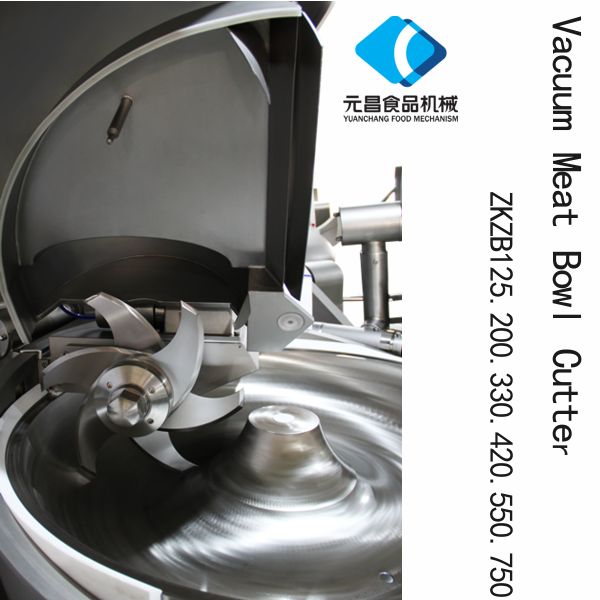

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang|Precision Food Processing&Hygiene Enhancement

The Vacuum Bowl Cutter ZKZB-125 represents a significant advancement in food processing technology, offering unparalleled efficiency, hygiene, and product quality. Developed by Hebei Yuanchang Food Mechanism & Technology Co., Ltd., this machine is designed to meet the demands of modern food production, particularly in the meat and pet food industries. Its innovative design and vacuum technology ensure that raw materials are processed with precision, preserving their nutritional value, texture, and shelf life. This article provides an in-depth exploration of the ZKZB-125's features, technical specifications, applications, and the company behind it, while also highlighting the importance of precision in food processing through a reference to the National Institute of Standards and Technology (NIST).

Product Overview

The Vacuum Bowl Cutter ZKZB-125 is a specialized food processing machine engineered to chop, mix, and homogenize raw materials under vacuum conditions. Its primary function is to enhance the quality of meat products and pet food by minimizing oxidation, preserving color, and extending shelf life. The machine's construction and operational principles reflect a deep understanding of food science and engineering, making it a valuable asset for manufacturers seeking to optimize their production processes.

Key Features and Design

The ZKZB-125 is constructed with a durable 304 stainless steel main body, ensuring resistance to corrosion and ease of cleaning. This material choice aligns with industry standards for food-grade equipment, prioritizing safety and longevity. The machine is equipped with observation and material filling holes, allowing operators to monitor the process and add ingredients without compromising the vacuum environment.

One of the most critical aspects of the ZKZB-125 is its vacuum system. By removing air from the processing chamber, the machine prevents oxidation, which can degrade the quality of meat and pet food. This process also helps retain the bright color of blood myoglobin and fat, ensuring visually appealing products. Additionally, the vacuum environment reduces the presence of bacteria, enhancing food safety and extending the shelf life of the final product.

Technical Specifications

| Feature | Specification |

|---|---|

| Material | 304 Stainless Steel |

| Processing Method | Vacuum Chopping and Mixing |

| Applications | Meat Processing, Pet Food Production |

| Key Benefits | Prevents Oxidation, Preserves Color, Enhances Shelf Life |

Advantages and Benefits

The Vacuum Bowl Cutter ZKZB-125 offers several distinct advantages over traditional food processing methods. By operating under vacuum conditions, it minimizes the risk of microbial contamination, a critical concern in the food industry. The removal of air from the processing chamber also reduces the formation of foam and improves the texture of the final product, making it more consistent and appealing to consumers.

Another significant benefit of the ZKZB-125 is its ability to preserve the natural color and flavor of raw materials. Oxidation, which often occurs during conventional chopping and mixing processes, can lead to discoloration and a loss of nutrients. The vacuum environment of the ZKZB-125 mitigates these issues, ensuring that the final product retains its original quality. This is particularly important for meat products, where color and texture are key factors in consumer satisfaction.

The machine's design also promotes efficiency and ease of use. The observation and material filling holes allow for real-time monitoring and adjustments, reducing the need for frequent interruptions. This feature is especially beneficial in high-volume production settings, where time and resource management are critical.

Applications in the Food Industry

The Vacuum Bowl Cutter ZKZB-125 is versatile, with applications spanning both the meat processing and pet food industries. In meat production, the machine is used to prepare ingredients for sausages, ground meats, and other processed products. The vacuum environment ensures that the meat remains fresh and retains its color, even after extended storage periods.

In the pet food sector, the ZKZB-125 is employed to create high-quality, nutritionally balanced diets for animals. The vacuum processing method preserves the integrity of ingredients, ensuring that pets receive the maximum nutritional benefit. This is particularly important for premium pet food brands that prioritize quality and health outcomes.

Moreover, the ZKZB-125's ability to handle a wide range of raw materials makes it suitable for small-scale and large-scale operations alike. Whether a manufacturer is producing specialty meats or bulk pet food, the machine's adaptability ensures it can meet diverse production needs.

Company Background: Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

Hebei Yuanchang Food Mechanism & Technology Co., Ltd. is a leading manufacturer of food processing equipment, specializing in innovative solutions for the meat and pet food industries. Based in Hebei, China, the company has established itself as a reliable provider of high-quality machinery that meets international standards. Its commitment to research and development ensures that its products are at the forefront of food technology.

Hebei Yuanchang's expertise in food machinery is evident in the design and functionality of the Vacuum Bowl Cutter ZKZB-125. The company's focus on precision engineering and user-friendly design reflects its dedication to customer satisfaction. By addressing the specific needs of food processors, Hebei Yuanchang has positioned itself as a key player in the global food machinery market.

The Role of Precision in Food Processing: A NIST Perspective

While the Vacuum Bowl Cutter ZKZB-125 exemplifies technological innovation, its effectiveness is closely tied to the principles of precision and standardization. The National Institute of Standards and Technology (NIST), a U.S. government agency, plays a vital role in establishing standards that ensure the accuracy and reliability of measurement and testing processes. As noted on the NIST website, "Everything you use in your everyday life works because of measurements. Without precise measurements, your car wouldn’t run, your phone wouldn’t work, and hospitals couldn’t function" (NIST).

In the context of food processing, precision is essential for maintaining product quality and safety. The vacuum technology employed by the ZKZB-125 relies on accurate control of pressure and temperature, which are critical parameters in food science. NIST's work in developing measurement standards and technologies supports the advancement of such innovations, ensuring that food processing equipment meets rigorous performance criteria.

The collaboration between industry leaders like Hebei Yuanchang and organizations like NIST underscores the importance of continuous improvement in food technology. By adhering to standardized practices, manufacturers can enhance the efficiency and safety of their operations, ultimately benefiting consumers.

Conclusion

The Vacuum Bowl Cutter ZKZB-125 is a testament to the power of innovation in food processing. Its vacuum technology, combined with a robust design and user-friendly features, makes it an indispensable tool for manufacturers in the meat and pet food industries. By prioritizing precision and quality, Hebei Yuanchang Food Mechanism & Technology Co., Ltd. has created a product that not only meets current industry demands but also sets a new benchmark for food processing equipment.

For those interested in exploring the Vacuum Bowl Cutter ZKZB-125 and other advanced food processing solutions, visiting Hebei Yuanchang Food Mechanism & Technology Co., Ltd.'s official website is recommended. The company's commitment to excellence and innovation ensures that its products remain at the forefront of the industry.

References

National Institute of Standards and Technology (NIST). (n.d.). Driving Innovation. Retrieved from https://www.nist.gov/

-

Meat Portioning Machine: Precision, Efficiency & Sustainability in Meat ProcessingNewsNov.24,2025

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025