Commercial Frozen Meat Slicer | Precision & Efficiency

The Crucial Role of Advanced Frozen Meat Slicing Technology in Modern Food Processing

In the rapidly evolving landscape of the global food industry, efficiency, hygiene, and product consistency are paramount. Modern food processing operations, from central kitchens to large-scale meat processors, demand equipment that can deliver high performance under stringent conditions. At the core of achieving uniform product quality and optimizing operational workflows, particularly in the preparation of protein, lies the sophisticated technology of the frozen meat slicer. This specialized machinery is engineered to precisely cut frozen blocks of meat into uniform slices, mitigating waste and significantly enhancing throughput. Understanding its technical intricacies, application versatility, and the underlying manufacturing excellence is critical for B2B decision-makers seeking to invest in robust and reliable solutions.

The market for advanced meat processing equipment is experiencing significant growth, driven by increasing consumer demand for pre-portioned and ready-to-cook meat products, as well as the imperative for improved food safety and reduced labor costs. Industry reports indicate that the global meat processing equipment market is projected to reach USD 17.5 billion by 2027, growing at a CAGR of 6.2%, with slicing and portioning technologies forming a substantial segment of this expansion. Innovations in blade technology, automation, and material science are continually pushing the boundaries of what these machines can achieve, offering businesses unprecedented levels of precision and operational efficiency. The strategic implementation of a high-performance frozen meat slicer is not just an investment in machinery; it's an investment in a resilient and competitive future for food processing enterprises.

Manufacturing Precision: The Process Flow of a High-Performance Frozen Meat Slicer

The development of a robust and hygienic frozen meat slicer involves a meticulously engineered manufacturing process, ensuring each component meets stringent quality and performance criteria. The journey from raw material to a sophisticated food processing machine is complex, emphasizing durability, precision, and adherence to international safety standards.

Schematic Manufacturing Steps:

- Material Selection & Procurement: Only food-grade materials are chosen. For critical contact parts, 304 or 316 stainless steel is specified for its superior corrosion resistance and ease of sanitation. Blades are crafted from high-carbon, wear-resistant tool steels (e.g., D2, H13) capable of maintaining sharpness under extreme conditions. Electrical components meet UL or CE standards.

- Component Fabrication (CNC Machining & Laser Cutting): Precision is paramount. Structural components, motor mounts, and enclosure panels are often laser-cut from stainless steel sheets, ensuring exact dimensions and smooth edges. Complex parts, such as gears, shafts, and specialized blade holders, undergo multi-axis CNC machining, guaranteeing micron-level tolerances critical for smooth operation and minimal vibration.

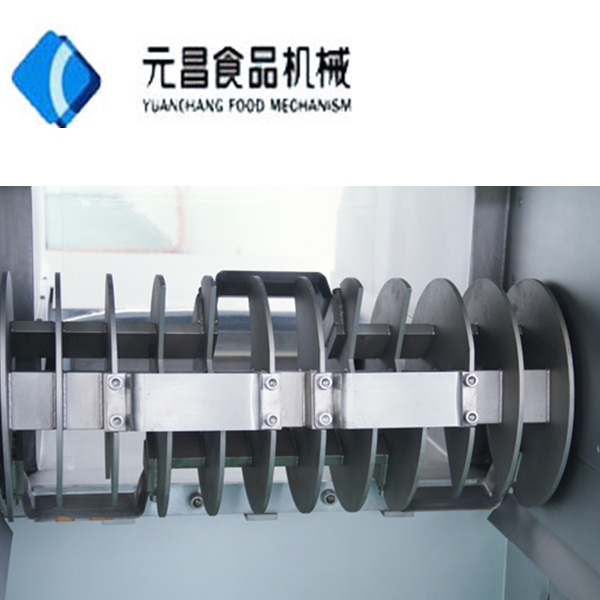

- Blade Manufacturing & Heat Treatment: The heart of any frozen meat slicer is its blade. Raw tool steel undergoes a specialized forging process to refine its grain structure, enhancing strength. This is followed by multi-stage heat treatment (hardening, tempering, cryo-treatment) to achieve optimal hardness (typically 58-62 HRC) and toughness. Precision grinding and honing then create an exceptionally sharp and durable cutting edge.

- Surface Finishing & Welding: All stainless steel components are polished to a high finish (e.g., Ra < 0.8 µm) to prevent bacterial adhesion and simplify cleaning. Welding processes, primarily TIG welding, are executed by certified technicians to ensure strong, seamless joints that are free from crevices, further enhancing hygiene.

- Assembly & Integration: Skilled technicians meticulously assemble the frame, motor, gearbox, feeding mechanism, and control systems. Electrical wiring and pneumatic connections (if applicable) are carefully routed and secured according to industry best practices.

- Quality Control & Testing: Each unit undergoes rigorous testing, adhering to ISO 9001 quality management standards. This includes:

- Dimensional Accuracy Checks: Ensuring all parts align perfectly.

- Functional Testing: Operating the machine at various speeds and loads with simulated frozen products.

- Safety Protocol Verification: Testing emergency stops, interlocks, and protective guards to meet ANSI/NFPA standards.

- Hygienic Design Validation: Ensuring all surfaces are easily cleanable and no 'dead spots' exist for bacterial growth.

- Noise and Vibration Analysis: Optimizing operational comfort and longevity.

- Final Calibration & Packaging: The slicing thickness is calibrated to ensure repeatable precision. The machine is then cleaned, inspected, and securely packaged for shipment, often meeting IPPC standards for international transit.

This detailed process ensures a service life often exceeding 10-15 years under typical operating conditions, driven by energy-efficient motors and minimal wear on corrosion-resistant components. While general manufacturing standards like ISO apply to the machine's construction, the application industries are squarely in food processing: large-scale meat packers, central catering kitchens, supermarkets, and specialty restaurants, where consistent portion control and high throughput are critical.

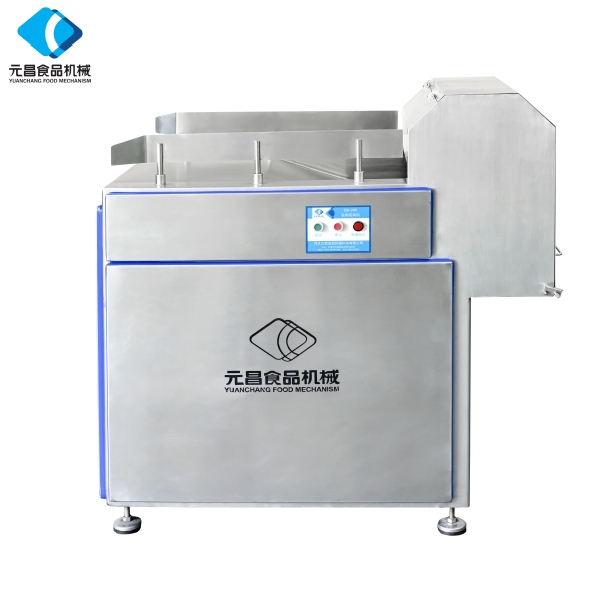

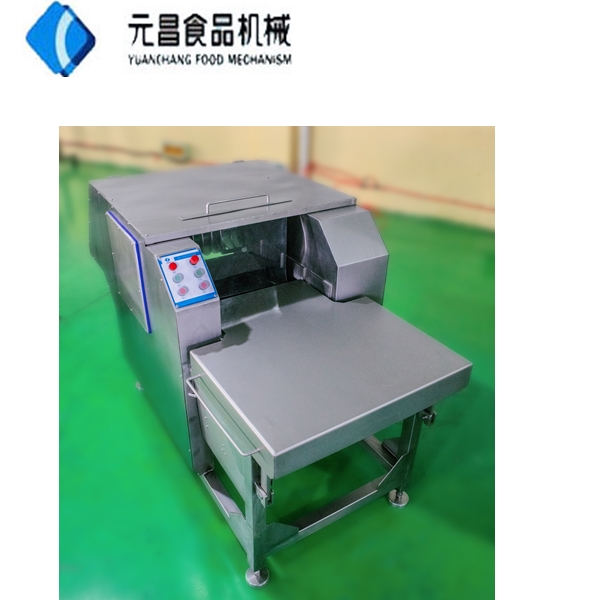

Technical Specifications and Design Principles of Advanced Frozen Meat Slicers

Modern frozen meat slicer units are engineered with a focus on delivering uncompromising performance, safety, and hygiene. Key design principles revolve around optimizing the cutting mechanism, ensuring robust power delivery, and facilitating effortless cleaning. Understanding the core technical parameters is crucial for selecting the right equipment for specific operational demands.

Core Components and Operational Parameters:

- Blade System: Features a high-speed rotating or reciprocating blade, often constructed from hardened stainless steel or alloy steel, designed for specific frozen meat densities. Blade types can include smooth, serrated, or scalloped, each optimized for different slicing profiles and meat types. Advanced models incorporate automatic blade sharpening systems to maintain optimal cutting performance.

- Feeding Mechanism: Utilizes a hydraulic or servo-motor-driven gripper system to securely hold and precisely feed frozen meat blocks into the blade. This ensures consistent slice thickness and prevents slippage, which is critical for safety and product uniformity.

- Motor & Drive System: High-torque, energy-efficient motors (typically 3-phase, 2-10 kW) power the blade and feeding mechanism. Variable Frequency Drives (VFDs) allow for precise speed control, adapting to different meat types and desired outputs while optimizing energy consumption.

- Control System: Modern machines are equipped with PLC (Programmable Logic Controller) based HMI (Human-Machine Interface) touchscreens. These interfaces allow operators to program slice thickness, count, batch size, and monitor operational parameters, enhancing user experience and precision.

- Safety Features: Comprehensive safety interlocks, emergency stop buttons, blade guards, and photoelectric sensors are standard, complying with CE, ETL, and NSF international safety standards to protect operators.

- Materials of Construction: Predominantly constructed from AISI 304 or 316 stainless steel for all contact surfaces and structural elements, ensuring maximum corrosion resistance, durability, and ease of sanitation to meet stringent FDA and HACCP guidelines.

Product Specification Table: Typical Commercial Frozen Meat Slicer

| Parameter | Specification |

|---|---|

| Model Series | ProSlice-M2000 Series |

| Slicing Capacity | Up to 800-1200 kg/hour (depending on meat type and thickness) |

| Slice Thickness Range | 0.5 mm - 30 mm (adjustable via HMI) |

| Max. Block Dimensions (L x W x H) | 600 mm x 300 mm x 200 mm |

| Blade Diameter / Type | Ø350 mm, High-carbon stainless steel circular blade |

| Motor Power | 5.5 kW (Blade), 1.5 kW (Feed), 0.75 kW (Hydraulic) |

| Power Supply | 3-Phase, 380V/50Hz or 480V/60Hz (Customizable) |

| Machine Dimensions (L x W x H) | 2500 mm x 1100 mm x 1600 mm |

| Weight | Approx. 850 kg |

| Certifications | CE, ISO 9001, HACCP-compliant design |

Application Scenarios and Industry Impact of the Frozen Meat Slicer

The versatility and precision of a frozen meat slicer make it an indispensable asset across a diverse range of food processing and service industries. Its ability to handle large blocks of frozen meat, including beef, pork, lamb, and poultry, with consistent slice thickness and minimal product waste, translates into significant operational advantages.

Target Industries and Specific Use Cases:

- Large-Scale Meat Processing Plants: Essential for preparing meat for further processing, such as grinding, dicing, or packaging. It ensures uniform input for subsequent machinery, improving overall line efficiency.

- Central Kitchens & Catering Companies: Critical for high-volume meal preparation, enabling precise portion control for dishes like stir-fries, hot pots, shabu-shabu, and deli meats. This consistency minimizes food costs and optimizes recipe adherence.

- Supermarkets & Hypermarkets: Used for in-store meat preparation, allowing for fresh slicing of various frozen meats on demand, presenting attractive and consistent product displays for consumers.

- Restaurants & Hotels: Especially in establishments specializing in Asian hotpot, barbecue, or fine dining, where perfectly thin and uniform slices of frozen lamb or beef are a hallmark of quality.

- Pet Food Manufacturers: Some formulations require precise slicing of frozen meat components before mixing, ensuring consistent product texture and nutrient distribution.

Demonstrated Advantages in Typical Application Scenarios:

- Enhanced Efficiency and Throughput: A commercial frozen meat slicer can process hundreds of kilograms of frozen meat per hour, drastically reducing manual labor and speeding up production cycles compared to thawing and manual slicing.

- Superior Product Consistency: Achieving exact slice thickness across entire batches is crucial for cooking uniformity, appealing presentation, and precise portion control. This is particularly vital for quality assurance in commercial settings.

- Reduced Meat Waste: Precision cutting minimizes trim and off-cuts, optimizing yield from expensive raw materials. The ability to slice meat while frozen prevents protein loss and maintains texture better than partially thawed methods.

- Improved Food Safety and Hygiene: By processing meat in a frozen state, the risk of bacterial proliferation during handling is significantly reduced. Modern slicers are designed for easy disassembly and cleaning, often with IP-rated components for wash-down procedures, adhering to HACCP principles.

- Energy Saving: Advanced motors with VFDs optimize power consumption based on load, leading to significant energy savings over prolonged operation compared to older, less efficient models.

Technical Advantages and Vendor Comparison in the Frozen Meat Slicer Market

When evaluating a meat slicer for frozen meat, understanding the underlying technical advantages and how different vendors differentiate their offerings is crucial for a strategic investment. Modern advancements provide significant operational benefits, setting high-quality machines apart.

Key Technical Advantages:

- Advanced Blade Technology: High-alloy, cryogenically treated blades offer extended sharpness retention and superior cutting performance, even with extremely hard frozen blocks. Automatic grinding systems further reduce downtime and maintenance.

- Hydraulic or Servo-Driven Precision Feeding: Eliminates manual interaction with frozen blocks, providing consistent feed rates and unparalleled slice accuracy, preventing 'shredding' or uneven cuts common with less advanced systems.

- Intuitive HMI and PLC Control: User-friendly touchscreens with programmable logic controllers enable precise control over slice thickness, speed, and batching parameters, minimizing operator error and maximizing efficiency. Recipe storage functionality allows for rapid switching between product types.

- Robust and Hygienic Construction: Full stainless steel construction (AISI 304/316) with seamless welds and polished surfaces prevents bacterial harborage and withstands aggressive cleaning regimes, ensuring compliance with global food safety standards like NSF and HACCP.

- Modular Design for Easy Maintenance: Components designed for quick disassembly and reassembly simplify cleaning, inspection, and part replacement, extending machine life and reducing maintenance costs.

- Energy Efficiency: Implementation of high-efficiency motors and variable frequency drives (VFDs) optimizes power consumption based on demand, leading to significant operational cost savings over the machine's lifespan.

Vendor Comparison: Evaluating Commercial Frozen Meat Slicers

Choosing the right vendor for a commercial frozen meat slicer involves more than just comparing spec sheets. It requires a holistic evaluation of product quality, after-sales support, customization capabilities, and long-term reliability. Below is a conceptual comparison table illustrating key differentiating factors:

| Feature/Vendor | Vendor A (Entry-Level) | Vendor B (Mid-Range) | YC Meat Mech (Premium) |

|---|---|---|---|

| Slicing Capacity (kg/hr) | 300-500 | 600-900 | 800-1200+ (High Throughput) |

| Slice Thickness Precision | ±1.5 mm | ±0.8 mm | ±0.3 mm (Exceptional) |

| Blade Material & Durability | Standard stainless steel, manual sharpening | Hardened stainless steel, semi-auto sharpening | Cryogenically-treated high-carbon steel, fully automatic sharpening |

| Control System | Button/dial based | Basic HMI, limited programming | Advanced PLC with intuitive multi-language HMI, recipe management |

| Hygiene & Cleaning | Basic stainless, some crevices | Food-grade stainless, good access | Full AISI 304/316, IP65 rating, tool-less disassembly, optimized for CIP |

| Safety Certifications | Basic CE | CE, ISO 9001 | CE, ISO 9001, HACCP-compliant design, NSF/UL optional |

| After-Sales Support | Limited local support | Regional service network | Global network, remote diagnostics, rapid spare parts fulfillment, dedicated technical support |

The choice of a frozen meat slicer commercial machine significantly impacts productivity, product quality, and long-term operational costs. Investing in a premium solution from a reputable manufacturer ensures not only high performance but also superior reliability and comprehensive support.

Customized Solutions and Real-World Application Case Studies

Recognizing that every food processing operation has unique requirements, leading manufacturers of frozen food slicer equipment offer extensive customization capabilities. These tailored solutions ensure seamless integration into existing production lines and optimize performance for specific product portfolios and operational scales.

Customization Options:

- Capacity and Throughput: Scalable designs to match production volumes, from mid-sized commercial kitchens to industrial processing plants requiring multi-ton per hour output.

- Slice Thickness and Profile: Specialized blade geometries and adjustable feed mechanisms to achieve ultra-thin shabu-shabu slices, thicker steak cuts, or specific chunk sizes for further processing.

- Block Feeding Systems: Integration with automated conveying systems, specialized loaders for irregular blocks, or multi-lane feeding for parallel processing.

- Outfeed and Packaging Integration: Direct integration with sorting, weighing, and packaging machinery to create a fully automated slicing and portioning line.

- Environmental Adaptations: Customizations for extreme temperature environments (e.g., cold rooms) or high-humidity operations, ensuring component longevity and reliable performance.

- Material Specifics: Adjustments to machine parameters and blade types for processing particularly hard frozen fish, vegetables, or specific types of frozen meat that present unique challenges.

Application Case Studies: Demonstrating Tangible Benefits

Case Study 1: Large-Scale Meat Processor - Increased Efficiency and Yield

A major North American meat processor faced challenges in achieving consistent slice thickness for their frozen beef products destined for fast-food chains. Their existing equipment resulted in significant trim waste and required frequent manual adjustments. By implementing a high-capacity, automated frozen meat slicer with servo-driven feeding, they achieved:

- 30% increase in hourly throughput, exceeding their previous capabilities.

- Reduced product waste by 8% due to precise, consistent slicing, leading to substantial raw material cost savings.

- Improved product consistency by 95%, ensuring all batches met stringent customer specifications.

- Reduced labor costs by 15% due to increased automation and reduced need for manual trimming.

Case Study 2: Regional Central Kitchen - Enhanced Portion Control and Food Safety

A rapidly expanding central kitchen supplying meals to schools and hospitals struggled with manual slicing of various frozen poultry and lamb for their meal programs. Inconsistent portion sizes led to budget overruns and difficulty in maintaining nutritional standards. Adopting a mid-range commercial frozen meat slicer integrated with a smart weighing system provided:

- Perfected portion control, eliminating over-portioning and reducing ingredient costs by 12%.

- Significant improvement in food safety scores, as frozen processing minimized bacterial exposure.

- Increased operational flexibility, allowing rapid switching between different meat types and slice requirements with pre-programmed recipes.

- Reduced cross-contamination risks through easy-to-clean design and designated blade systems for different meat types.

Ensuring Trustworthiness: FAQs, Lead Time, Warranty, and Customer Support

Trust is built on transparency, reliability, and robust support. As a committed partner, we ensure our clients have all necessary information regarding our frozen meat slicer solutions, from initial inquiry through years of operation.

Frequently Asked Questions (FAQs):

- Q: What types of frozen meat can this slicer handle?

A: Our machines are designed to efficiently slice various types of frozen meat, including beef, lamb, pork, poultry, and even some fish, provided they are in block form and within the specified temperature range (-4°C to -18°C typically).

- Q: What is the ideal operating temperature for frozen meat?

A: For optimal performance and blade longevity, frozen meat should be between -4°C and -18°C. Meat that is too hard (e.g., below -20°C) can cause excessive blade wear, while partially thawed meat can result in uneven or shredded slices.

- Q: How often does the blade need sharpening or replacement?

A: With our automatic sharpening system, blades maintain optimal sharpness for extended periods. The frequency of sharpening depends on usage volume and meat hardness, but typically, a monthly or bi-monthly sharpening cycle is sufficient. Blade replacement is generally recommended every 12-24 months under normal operation.

- Q: Is the machine easy to clean and sanitize?

A: Yes, our frozen meat slicer features an ergonomic, sanitary design. Key components are easily removable without tools for thorough cleaning. All food-contact surfaces are polished stainless steel, and the machine is designed for comprehensive wash-down procedures, meeting IP65 standards for electrical components.

- Q: Can the machine be integrated into an existing processing line?

A: Absolutely. Our engineering team specializes in providing customized solutions, including seamless integration with upstream and downstream equipment such as conveyors, weighers, and packaging machines. We offer full layout design and installation support.

Lead Time and Fulfillment:

Standard models of our frozen meat slicer typically have a lead time of 4-6 weeks from order confirmation to shipment. Custom-engineered solutions or large-scale projects may require 8-12 weeks, depending on the complexity of customization and specific component sourcing. We maintain a robust supply chain and efficient manufacturing processes to ensure timely delivery. Detailed production schedules and delivery milestones are provided upon order confirmation.

Warranty Commitments:

We stand by the quality and durability of our equipment. All our frozen meat slicer commercial models come with a comprehensive 12-month warranty covering manufacturing defects and component failures under normal operating conditions. Extended warranty options and service contracts are available to provide additional peace of mind for long-term operations.

Customer Support and After-Sales Service:

Our commitment to our clients extends far beyond the sale. We offer world-class after-sales support, including:

- Technical Assistance: A dedicated team of engineers provides remote and on-site technical support for troubleshooting, maintenance, and operational guidance.

- Spare Parts Management: We maintain a comprehensive inventory of genuine spare parts, ensuring quick availability and minimizing downtime. Critical parts can be dispatched within 24-48 hours.

- Training Programs: On-site operator and maintenance training is provided during installation to ensure your team is fully proficient in operating and maintaining the equipment safely and efficiently.

- Preventative Maintenance Plans: We offer tailored preventative maintenance programs to extend machine life, optimize performance, and prevent unexpected breakdowns.

Conclusion: Driving Excellence with Advanced Frozen Meat Slicing Solutions

The modern food processing industry demands precision, efficiency, and uncompromised hygiene. The advanced frozen meat slicer stands as a testament to engineering excellence, providing solutions that not only meet but exceed these stringent requirements. From optimizing throughput and reducing waste to ensuring superior product consistency and enhancing food safety, the strategic integration of a high-quality frozen meat slicer is a critical investment for any forward-thinking B2B entity in the meat processing sector. As technology continues to evolve, incorporating smart features and greater automation, the capabilities of these machines will only grow, further solidifying their role as indispensable assets in the global food supply chain. Partnering with a reputable manufacturer that offers both cutting-edge technology and comprehensive support ensures a resilient, efficient, and profitable future.

References

- Global Meat Processing Equipment Market Report 2023, Grand View Research.

- Food and Drug Administration (FDA) Guidance for Industry: Sanitary Design and Construction of Equipment for Meat and Poultry Products.

- International Organization for Standardization (ISO) 9001:2015 - Quality Management Systems - Requirements.

- NSF International Standard 8: Commercial Powered Food Preparation Equipment.

- Hazard Analysis and Critical Control Points (HACCP) Principles and Application Guidelines.

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025

-

Best Commercial Marinating Machines for Meat Processing | Efficient & ScalableNewsNov.20,2025