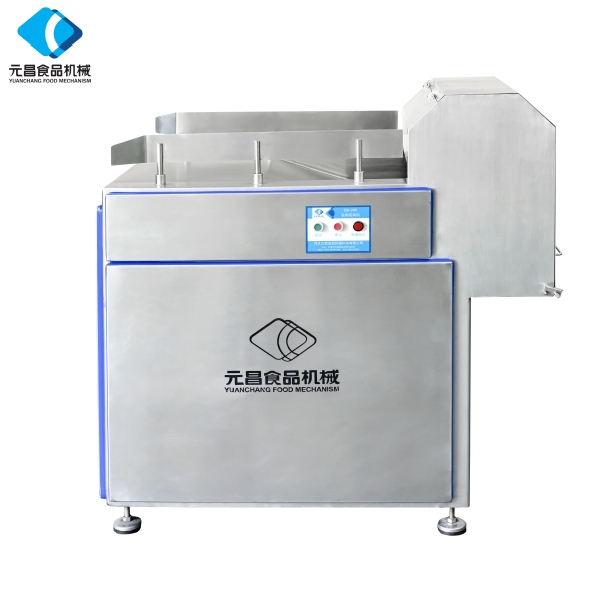

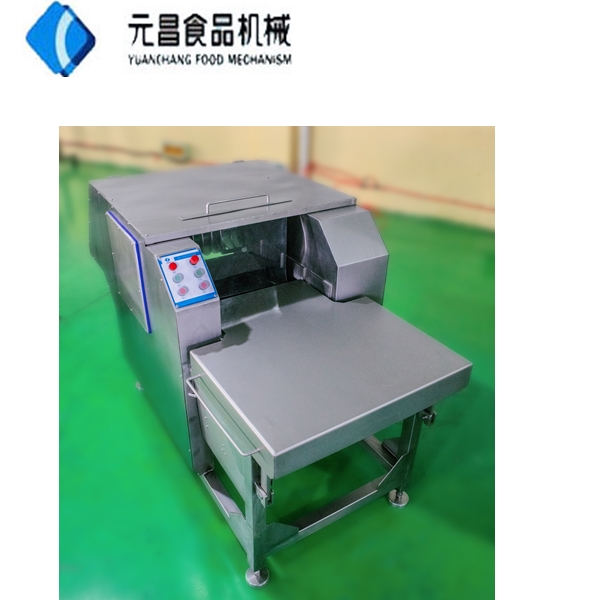

Commercial Frozen Meat Slicer - Effortless & Precision Cuts

The Evolution of Precision: Decoding the Frozen Meat Slicer Industry

In the rapidly evolving food processing sector, the demand for efficiency, hygiene, and consistency has propelled specialized machinery to the forefront. Among these, the frozen meat slicer stands as a cornerstone technology, essential for businesses ranging from large-scale industrial kitchens and meat processing plants to high-volume restaurants and supermarkets. This sophisticated equipment is meticulously designed to process various types of frozen meats, including beef, lamb, pork, and poultry, into uniform slices or chunks, optimizing preparation times and ensuring product integrity. The global market for meat processing equipment, encompassing solutions like the meat slicer for frozen meat, is projected to reach substantial growth, driven by increasing meat consumption, the expansion of the processed food industry, and stringent food safety regulations. Innovations in automation, material science, and intelligent control systems are continuously reshaping the capabilities of these machines, offering unparalleled precision, enhanced operational safety, and significant cost savings. The adoption of advanced frozen food slicer technology is not merely an operational upgrade but a strategic investment that fundamentally impacts production throughput, product quality, and competitive advantage in a demanding market. Understanding its technical nuances, application versatility, and manufacturing excellence is crucial for any stakeholder aiming to optimize their processing lines and elevate their product offerings.

The demand for an efficient frozen meat slicer commercial solution is particularly acute in settings where high volume and consistent quality are paramount. Modern food service operations and industrial processing facilities rely on these machines to maintain strict portion control, reduce manual labor, and minimize waste, all of which directly contribute to improved profit margins. The latest models often incorporate features such as adjustable slicing thickness, automated feeding systems, and advanced safety interlocks, reflecting a commitment to both operational excellence and worker protection. Furthermore, the emphasis on hygienic design and ease of cleaning is a critical factor, aligning with global food safety standards such as HACCP (Hazard Analysis and Critical Control Points) and FDA guidelines for food contact materials. This ensures that the sliced products maintain their freshness and are free from contamination. The ongoing research and development in this sector also focus on integrating IoT capabilities for predictive maintenance and performance monitoring, allowing operators to gain real-time insights into machine efficiency and potential issues. This proactive approach to maintenance not only extends the service life of the equipment but also significantly reduces unexpected downtime, ensuring a continuous and uninterrupted production flow. As the food industry continues its trajectory towards greater automation and higher standards, the role of a robust and reliable commercial frozen meat slicer becomes increasingly indispensable, defining the operational efficiency and product quality of leading businesses worldwide.

Craftsmanship and Engineering: The Manufacturing Process of a Frozen Meat Slicer

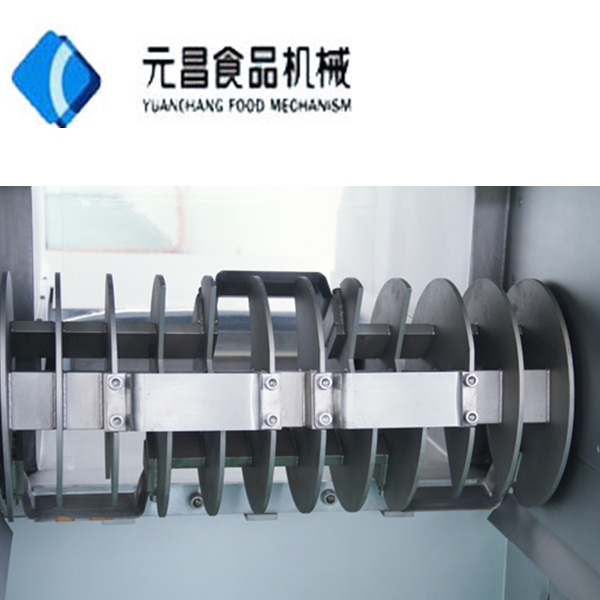

The journey of a high-performance frozen meat slicer from raw material to a precision machine involves a meticulous manufacturing process, underpinned by advanced engineering principles and stringent quality control. The selection of materials is paramount; components that come into contact with food are typically crafted from food-grade stainless steel (e.g., SUS304 or SUS316L), renowned for its excellent corrosion resistance, hygiene, and durability, thereby meeting international standards like NSF and FDA. Key structural components, requiring exceptional strength and stability, often utilize advanced alloys or cast iron, treated for enhanced resilience. The manufacturing process itself frequently begins with precision casting or forging for foundational elements, followed by sophisticated CNC (Computer Numerical Control) machining. CNC technology ensures unparalleled accuracy in shaping complex parts, achieving micron-level tolerances critical for smooth operation, minimal vibration, and extended service life. For example, the blade assembly, the heart of any meat slicer for frozen meat, undergoes multi-stage CNC grinding and hardening processes to achieve optimal sharpness, edge retention, and resistance to wear, often utilizing specialized high-carbon chromium steel or ceramic-coated blades for superior performance in extremely low temperatures.

Beyond material selection and shaping, the assembly and testing phases are crucial for ensuring the reliability and longevity of a frozen food slicer. Each sub-assembly, from the motor drive system to the feeding mechanism and safety interlocks, is carefully integrated. Motors are often high-torque, energy-efficient units designed for continuous operation under heavy loads, frequently equipped with intelligent overload protection. Quality control is maintained throughout every stage, adhering to international benchmarks such as ISO 9001 for quality management systems and specific machinery safety directives like CE (Conformité Européenne) marking for the European market, which signifies compliance with health, safety, and environmental protection standards. Post-assembly, each commercial frozen meat slicer undergoes rigorous performance testing, including stress tests, noise level assessments, vibration analysis, and repeated slicing trials with various frozen meat types to ensure consistent output quality and operational stability. This comprehensive testing ensures that the equipment can withstand the rigors of industrial use, offering an impressive service life typically ranging from 10 to 15 years with proper maintenance. The meticulous attention to detail in manufacturing ensures that these machines deliver not only high precision and output but also demonstrate exceptional energy efficiency and superior corrosion resistance, reducing operational costs and ensuring food safety over their operational lifespan. This commitment to engineering excellence underpins the reliability and high performance expected by B2B clients in the demanding food processing industry.

Key Technical Parameters of a High-Performance Frozen Meat Slicer

Understanding the technical parameters of a frozen meat slicer is essential for optimizing its performance and ensuring it meets specific operational requirements. The core components define the machine's capability: the motor's power output (typically ranging from 1.5 kW to 7.5 kW or higher for industrial models) dictates the slicing force and speed, allowing the machine to process hard-frozen blocks efficiently. Blade diameter and material are critical; larger diameters (e.g., 300mm to 500mm) allow for processing larger meat chunks, while specialized alloys like 420J2 stainless steel or even high-performance ceramics ensure durability, sharpness, and resistance to low temperatures. Slicing thickness is usually adjustable, offering a range from 0.5mm to 30mm, catering to diverse culinary applications from thinly sliced deli meats to thicker stew cuts. Capacity, measured in kilograms per hour (kg/h), can vary significantly, from 100 kg/h for smaller commercial units to over 2000 kg/h for heavy-duty industrial frozen meat slicer commercial models, reflecting their throughput capabilities. Advanced models often feature PLC (Programmable Logic Controller) based control systems with HMI (Human-Machine Interface) touchscreens, providing intuitive operation, precise parameter setting, and diagnostic feedback, further enhancing efficiency and reducing the need for extensive operator training.

| Parameter | Value Range (Typical) | Significance for Frozen Meat Slicer |

|---|---|---|

| Motor Power | 1.5 kW - 7.5 kW | Higher power for denser frozen blocks and continuous operation, ensuring consistent slicing force. |

| Blade Material | 420J2 Stainless Steel, High-Carbon Chromium Steel | Ensures sharpness, durability, and corrosion resistance at low temperatures, crucial for a frozen food slicer. |

| Slicing Thickness | 0.5 mm - 30 mm (adjustable) | Versatility for different product requirements, from paper-thin shabu-shabu slices to thicker stew chunks. |

| Production Capacity | 100 kg/h - 2000+ kg/h | Indicates throughput capabilities, critical for matching production volume demands in a meat slicer for frozen meat. |

| Dimensions (LxWxH) | Varies by model | Space requirement planning for industrial kitchens or processing lines. |

| Weight | 150 kg - 800 kg+ | Indicates robust construction and stability during operation. |

| Noise Level | Typically | Important for workplace safety and compliance with occupational health standards. |

| Safety Features | Emergency Stop, Blade Guards, Interlocks | Essential for operator protection and compliance with international safety regulations like CE, ANSI. |

Beyond these fundamental parameters, advanced considerations include the type of feeding system (manual, semi-automatic, or fully automatic), which significantly impacts labor requirements and speed, and the integration of self-cleaning or quick-disassembly features for enhanced sanitation. Energy efficiency is another critical technical parameter, with modern frozen meat slicer models incorporating high-efficiency motors and optimized mechanical designs to minimize power consumption, leading to lower operating costs over time. For example, a well-designed motor and transmission system can reduce energy consumption by up to 20% compared to older models, translating into substantial savings for high-volume operations. Additionally, the ability of the machine to handle various meat temperatures, ranging from partially frozen to hard-frozen, without compromising slice quality or machine integrity, speaks to its robust engineering. The precision of the slicing mechanism, often involving sophisticated servo-driven systems, ensures minimal product waste due to uneven cuts, directly contributing to higher yield and better profitability. The summation of these technical aspects defines the superior performance, reliability, and long-term value that a professional-grade frozen food slicer offers to the food industry.

Beyond Slicing: Diverse Application Scenarios & Strategic Advantages

The utility of a frozen meat slicer extends far beyond its primary function, embedding itself as a critical asset across a multitude of sectors within the food industry. In large-scale meat processing plants, it streamlines the production of deli meats, portioned steaks, and ground meat bases, allowing for efficient packaging and distribution. Restaurants, particularly those specializing in hot pot, shabu-shabu, or fine dining, leverage the precision of a meat slicer for frozen meat to create consistent, paper-thin slices that cook rapidly and absorb flavors exquisitely, enhancing the dining experience and ensuring culinary consistency. Supermarkets and butcher shops utilize these machines for on-demand slicing of frozen meat blocks into retail-ready portions, significantly improving customer convenience and reducing labor costs associated with manual preparation. Furthermore, the burgeoning prepared meal industry relies heavily on these machines to portion ingredients accurately for ready-to-cook meal kits. This broad applicability highlights the machine's versatility and its capacity to meet diverse operational demands, from high-volume industrial production to precise culinary requirements. The adoption of an advanced frozen food slicer enables businesses to elevate their product consistency, improve presentation, and respond swiftly to market demands for specific cuts and portion sizes, fostering greater customer satisfaction and market competitiveness.

The strategic advantages offered by a high-quality commercial frozen meat slicer are multifaceted, extending beyond mere operational efficiency. One significant benefit is substantial energy savings, as modern slicers are engineered with optimized motor systems and efficient blade designs that minimize friction and power consumption during the slicing process, leading to lower utility bills. For instance, some industrial models incorporate variable frequency drives (VFDs) which adjust motor speed according to load, resulting in energy consumption reductions of up to 15-25% compared to fixed-speed machines. Another critical advantage is enhanced corrosion resistance, especially crucial in food environments where moisture and cleaning agents are prevalent. Components made from marine-grade stainless steel or with specialized surface treatments ensure the machine's longevity and adherence to stringent hygiene standards, preventing rust and microbial growth. This durability translates into lower maintenance costs and a longer operational lifespan. Moreover, the precision cutting capabilities of a frozen meat slicer commercial significantly reduce meat waste, maximizing yield from expensive raw materials. The ability to produce uniform slices ensures consistent cooking times and product quality, which is vital for brand reputation and customer loyalty. This blend of energy efficiency, robust construction, and precision slicing collectively represents a compelling value proposition, making these machines an indispensable investment for any food processing entity striving for operational excellence and sustainable growth in a competitive global market.

Choosing Your Partner: Manufacturer Comparison and Customization Solutions

Selecting the right manufacturer for a frozen meat slicer is a critical decision that profoundly impacts operational reliability, product quality, and long-term cost of ownership. When comparing manufacturers, key considerations include their reputation, years of industry experience, and adherence to international quality and safety certifications such as ISO 9001, CE, and HACCP compliance for food machinery. A reputable manufacturer will often demonstrate a deep understanding of food processing dynamics, offering not just a product but a comprehensive solution. This includes expertise in blade metallurgy, motor efficiency, control system integration, and hygienic design. Client testimonials, case studies, and available technical support infrastructure are also strong indicators of a manufacturer's commitment to customer satisfaction and after-sales service. For instance, a manufacturer with a proven track record of over 15 years in producing the meat slicer for frozen meat will likely offer more robust designs, superior material selection, and more refined operational logic based on extensive field feedback. Prospective buyers should meticulously evaluate warranties, spare parts availability, and the responsiveness of technical support teams, as these factors directly influence uptime and productivity, particularly for high-volume operations that cannot afford prolonged interruptions.

Beyond standard models, the ability to provide customized solutions is a significant differentiator for a frozen food slicer manufacturer. While many commercial operations can utilize off-the-shelf equipment, specific production lines may require bespoke modifications to optimize workflow, integrate with existing machinery, or meet unique product specifications. Customization options can range from specific blade types and sizes for particular meat textures, specialized conveyor systems for automated feeding and discharge, to integration with upstream or downstream processing equipment like tenderizers or packaging machines. For a commercial frozen meat slicer, this might also involve adapting the machine's footprint to fit restricted spaces, enhancing the motor power for higher density products, or implementing advanced sensor arrays for precision weight control. Collaborating with a manufacturer who possesses robust engineering and R&D capabilities allows businesses to design a tailored solution that addresses their precise operational bottlenecks, maximizes throughput, and enhances overall efficiency. This partnership approach, where the manufacturer acts as a consultant to understand unique challenges and propose innovative engineering solutions, ensures that the investment in a frozen meat slicer commercial translates into a strategically optimized asset, yielding significant competitive advantages and long-term returns for the business.

Real-World Impact: Illustrative Application Cases and Success Stories

The tangible benefits of deploying a high-quality frozen meat slicer are best illustrated through real-world application cases, showcasing how these machines transform operational capabilities and business outcomes. Consider a large-scale food service supplier specializing in bulk frozen meat distribution for institutional catering. Before adopting an automated meat slicer for frozen meat, their process involved time-consuming manual cutting or relying on smaller, less efficient machines, resulting in inconsistent portion sizes and significant labor costs. Post-implementation of a high-capacity industrial frozen meat slicer, this supplier observed a remarkable 40% reduction in processing time and a 15% improvement in portion consistency, directly leading to reduced material waste and increased output. This efficiency gain allowed them to take on larger contracts, enhancing their market share and profitability. Another compelling example comes from a burgeoning chain of hot pot restaurants, where the demand for perfectly thin, uniformly sliced meat is paramount. By investing in a dedicated frozen food slicer, they were able to standardize their meat preparation across all locations, ensuring every customer received the same high-quality product. This consistency not only elevated their brand reputation but also significantly improved kitchen efficiency during peak hours, as the pre-sliced meat was ready for immediate serving.

Furthermore, the integration of a commercial frozen meat slicer often leads to unforeseen positive externalities, such as improved workplace safety and enhanced hygiene protocols. In a traditional butchery environment, manual slicing of frozen meat poses considerable risks of injury due to the hardness of the material and the sharpness of knives. The automated nature of modern slicers, combined with their advanced safety interlocks and protective guards, drastically mitigates these risks, contributing to a safer working environment. From a hygiene perspective, the stainless-steel construction and easy-to-clean design of these machines minimize areas for bacterial growth, ensuring compliance with strict food safety regulations like HACCP. A packaged meal producer, for instance, implemented a new frozen meat slicer commercial system with automated cleaning cycles, which reduced their daily sanitation time by 25% and demonstrably improved their microbial count testing results. These success stories underscore that investing in a state-of-the-art frozen meat slicer is not merely an expense but a strategic decision that drives operational excellence, ensures product integrity, and fosters sustainable growth in the highly competitive food processing landscape. The direct impact on efficiency, waste reduction, and safety makes it a cornerstone technology for modern food businesses.

Ensuring Trust and Reliability: FAQs and Comprehensive Customer Support

Building trust with B2B clients requires more than just offering a superior product; it necessitates transparent communication and robust support infrastructure. For a critical piece of equipment like a frozen meat slicer, prospective buyers frequently have a range of questions regarding its operation, maintenance, and longevity. A comprehensive FAQ section can preemptively address common concerns, demonstrating expertise and commitment to customer education. Typical questions might include: "What is the optimal temperature for slicing various meats?", "How frequently should the blades be sharpened or replaced?", "What are the power requirements and installation procedures?", or "Can the machine handle bones or partially thawed meat?" Addressing these queries with clear, concise, and technically accurate answers enhances a client's understanding and confidence in the product. Furthermore, clarity on delivery timelines is crucial for operational planning. Manufacturers typically provide estimated delivery windows (e.g., 4-8 weeks depending on customization and shipping destination), outlining factors that might influence these timelines, such as component availability or specific customization requests for a meat slicer for frozen meat. This transparency helps clients schedule their production line adjustments and minimizes disruptions.

A strong warranty and comprehensive customer support are cornerstones of reliability for a frozen food slicer. Standard warranties for industrial machinery typically range from 1 to 3 years, covering manufacturing defects and major component failures. Beyond this period, reputable manufacturers often provide extended warranty options or maintenance contracts. Clear service level agreements (SLAs) for technical support, outlining response times for inquiries or on-site service, are vital for businesses that cannot afford prolonged downtime. This support can range from remote diagnostics and troubleshooting via phone or video calls to dispatching skilled technicians for complex repairs. Availability of genuine spare parts is another critical aspect, ensuring that routine maintenance and repairs can be conducted efficiently without long delays, thus maximizing the uptime of the commercial frozen meat slicer. Training programs for client personnel on proper operation, cleaning, and basic troubleshooting also contribute significantly to the longevity and efficient use of the equipment, preventing common errors and reducing the need for professional service calls. This holistic approach to customer support, from pre-sales inquiries to post-warranty service, solidifies a manufacturer's trustworthiness and reinforces the value proposition of their frozen meat slicer commercial offerings, fostering long-term partnerships built on reliability and mutual success.

References

- Journal of Food Engineering. (2022). Advances in Meat Processing Technologies for Enhanced Quality and Safety.

- Food Technology. (2023). Automation and Robotics in the Meat Industry: Trends and Challenges.

- Meat Science. (2021). Impact of Freezing and Slicing Techniques on Meat Texture and Sensory Attributes.

- International Journal of Production Economics. (2023). Optimizing Production Lines in Food Manufacturing Through Predictive Maintenance and IoT Integration.

- Food Control. (2022). Hygienic Design Principles for Food Processing Equipment: A Review of International Standards and Best Practices.

-

Meat Portioning Machine: Precision, Efficiency & Sustainability in Meat ProcessingNewsNov.24,2025

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025