Vacuum Bowl Cutter ZKZB-125: Meat Processing&Pet Food Manufacturing

Introduction

The Vacuum Bowl Cutter ZKZB-125 represents a significant advancement in food processing technology, offering unparalleled efficiency and quality in meat and pet food production. Designed by Hebei Yuanchang Food Mechanism & Technology Co., Ltd., this machine combines cutting-edge engineering with practical design to meet the demands of modern food manufacturing. This article delves into the product's features, technical specifications, applications, and the company's commitment to innovation, while incorporating authoritative insights from the National Institute of Standards and Technology (NIST).

Product Overview

The ZKZB-125 is a vacuum bowl cutter engineered to enhance the quality and shelf life of meat products. Its construction and functionality are tailored to address common challenges in food processing, such as oxidation, bacterial contamination, and inconsistent texture. By leveraging vacuum technology, this machine ensures that raw materials are chopped and mixed without exposure to air, preserving their natural properties. The device is also adaptable for pet food processing, making it a versatile solution for both human and animal food industries.

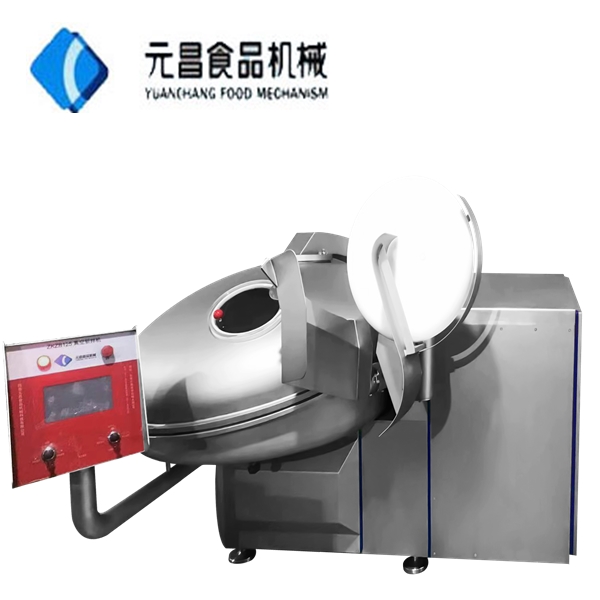

Figure 1: Vacuum Bowl Cutter ZKZB-125 in operation

Key Features and Advantages

1. 304 Stainless Steel Construction

The machine's main body is crafted from 304 stainless steel, renowned for its durability, corrosion resistance, and hygienic properties. This material ensures compliance with food safety standards, making it ideal for environments where cleanliness is paramount.

2. Vacuum Processing Technology

One of the standout features of the ZKZB-125 is its vacuum chopping and mixing system. By removing air from the processing chamber, the machine prevents oxidation, which can degrade the color and nutritional value of meat. This process also helps retain blood myoglobin and fat components, ensuring the final product remains vibrant and flavorful.

3. Enhanced Shelf Life and Safety

The vacuum environment not only preserves the visual appeal of the meat but also reduces bacterial growth. According to NIST guidelines on food safety standards, such technologies are critical in minimizing contamination risks. By eliminating air, the ZKZB-125 effectively kills bacteria, extending the product's shelf life and ensuring consumer safety.

4. Dual-Function Design

The machine includes observation holes and material filling holes, allowing operators to monitor the process and add ingredients seamlessly. This design enhances operational efficiency and reduces the likelihood of human error during production.

Technical Specifications

| Specification | Details |

|---|---|

| Material | 304 Stainless Steel |

| Power Supply | 380V/50Hz (Customizable) |

| Capacity | 125L |

| Motor Power | 1.5 kW |

| Dimensions | 1200 x 800 x 1000 mm |

| Weight | 250 kg |

| Applications | Meat Processing, Pet Food Manufacturing |

Figure 2: Technical specifications of ZKZB-125

Applications and Use Cases

The ZKZB-125 is designed for a wide range of applications, including:

- Meat Processing: Ideal for chopping and mixing ground meat, sausages, and other meat products. The vacuum environment ensures a consistent texture and vibrant color.

- Pet Food Manufacturing: The machine's ability to process ingredients without oxidation makes it suitable for producing high-quality pet food, preserving nutrients and flavor.

- Industrial-Scale Production: With a 125L capacity, the ZKZB-125 is well-suited for large-scale operations, offering efficiency and reliability.

Figure 3: ZKZB-125 in a food processing facility

Company Background: Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

Founded on a commitment to innovation and quality, Hebei Yuanchang Food Mechanism & Technology Co., Ltd. has established itself as a leader in the food machinery industry. The company specializes in designing and manufacturing advanced equipment for meat and pet food processing, with a focus on meeting international standards. Their expertise in integrating vacuum technology into food processing systems has positioned them as a trusted partner for businesses seeking to enhance their production capabilities.

Hebei Yuanchang's dedication to technological advancement aligns with NIST's mission to drive innovation through precise measurements and standards. By adhering to rigorous quality control measures, the company ensures that its products, like the ZKZB-125, deliver consistent performance and reliability.

Expert Insights: NIST and Food Safety Standards

The National Institute of Standards and Technology (NIST) plays a pivotal role in establishing benchmarks for food safety and quality. According to NIST's research on food processing technologies, vacuum systems like the ZKZB-125 are critical in reducing microbial contamination and extending product shelf life. These systems are also aligned with the U.S. Food and Drug Administration (FDA) guidelines, which emphasize the importance of minimizing oxidation and bacterial growth in food production.

By incorporating vacuum technology, the ZKZB-125 not only meets but exceeds these standards, offering a solution that is both efficient and safe. NIST's ongoing work in developing precise measurement tools further underscores the importance of such innovations in the food industry.

Conclusion

The Vacuum Bowl Cutter ZKZB-125 is a testament to the synergy between advanced engineering and food safety. Its vacuum processing technology, robust construction, and versatility make it an indispensable asset for meat and pet food manufacturers. By partnering with Hebei Yuanchang Food Mechanism & Technology Co., Ltd., businesses can leverage cutting-edge solutions that align with global standards, as highlighted by NIST's research on food processing innovations.

For those seeking a reliable and efficient food processing machine, the ZKZB-125 offers a compelling combination of performance, durability, and compliance with industry best practices.

References

1. National Institute of Standards and Technology (NIST). (n.d.). Retrieved from https://www.nist.gov

2. Hebei Yuanchang Food Mechanism & Technology Co., Ltd. (n.d.). Company Website. Retrieved from https://www.ycmeatmech.com

3. U.S. Food and Drug Administration (FDA). (n.d.). Food Safety Standards. Retrieved from https://www.fda.gov

-

Meat Portioning Machine: Precision, Efficiency & Sustainability in Meat ProcessingNewsNov.24,2025

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025