Introduction

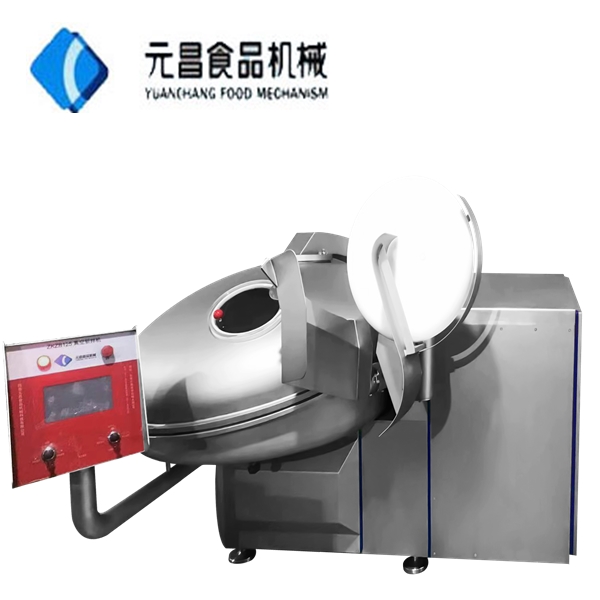

The Vacuum Bowl Cutter ZKZB-125 represents a significant advancement in food processing technology, designed to enhance efficiency, product quality, and safety in both meat and pet food industries. Developed by Hebei Yuanchang Food Mechanism & Technology Co., Ltd., this machine integrates cutting-edge engineering with practical design to meet the demands of modern food production. This article provides an in-depth analysis of the ZKZB-125's features, technical specifications, applications, and the company's commitment to innovation.

Product Overview

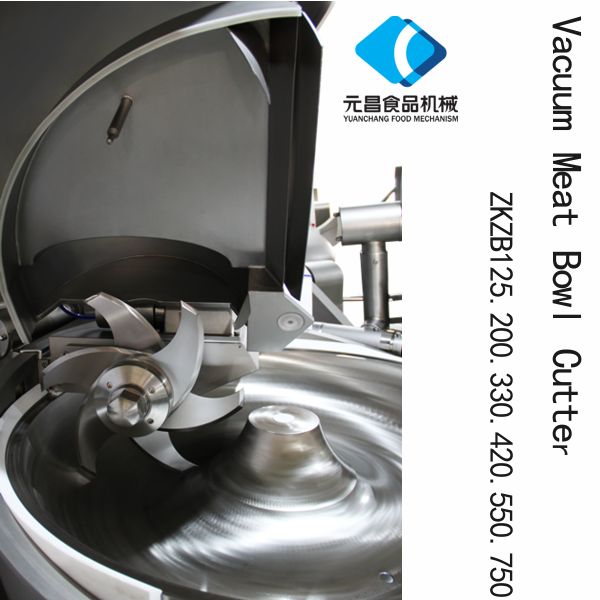

The Vacuum Bowl Cutter ZKZB-125 is a specialized piece of equipment designed for chopping and mixing raw materials under vacuum conditions. Its primary function is to process meat and pet food ingredients while minimizing oxidation and preserving the integrity of the product. The machine's construction and operational principles are tailored to meet the rigorous standards of food safety and efficiency.

Key components of the ZKZB-125 include a durable 304 stainless steel body, which ensures resistance to corrosion and easy cleaning. The machine is equipped with observation holes and material filling holes, allowing operators to monitor the process and add ingredients as needed. These design features not only enhance usability but also contribute to the machine's reliability in industrial settings.

Key Features and Benefits

1. Vacuum Processing Technology

The ZKZB-125 employs vacuum technology to remove air from the processing chamber, which significantly reduces the risk of oxidation. This process preserves the color, texture, and nutritional value of the raw materials. According to the National Institute of Standards and Technology (NIST), precise control of environmental conditions during food processing is critical for maintaining product quality and safety (NIST, 2025).

2. Enhanced Product Quality

By eliminating air and reducing bacterial contamination, the ZKZB-125 ensures that the final product retains its natural color and freshness. The vacuum environment also helps in preserving blood myoglobin, fat, and other essential components, resulting in a more appealing and nutritious end product. This is particularly important in the meat processing industry, where consumer preferences for high-quality, visually appealing products are paramount.

3. Versatility in Applications

The ZKZB-125 is not limited to meat processing; it can also be used for pet food production. This versatility makes it an attractive investment for businesses looking to diversify their product lines. The machine's ability to handle various types of raw materials ensures that it can adapt to different processing requirements.

4. User-Friendly Design

The inclusion of observation and material filling holes allows for real-time monitoring and adjustments during the processing. This feature is particularly beneficial for operators who need to ensure consistent quality and efficiency. The machine's design also facilitates easy maintenance and cleaning, which is essential for compliance with food safety regulations.

Technical Specifications

| Specification | Details |

|---|---|

| Material Construction | 304 Stainless Steel |

| Processing Capacity | Varies based on model (see product page for specifics) |

| Vacuum System | Integrated vacuum chamber for air removal |

| Observation Holes | Equipped for real-time monitoring |

| Material Filling Holes | Designed for convenient ingredient addition |

| Applications | Meat processing, pet food production |

Applications and Industry Impact

The Vacuum Bowl Cutter ZKZB-125 is widely used in the food processing industry, particularly in meat and pet food manufacturing. Its ability to maintain product quality and safety makes it an essential tool for businesses aiming to meet consumer demands for high-quality, safe, and nutritious products. According to the NIST, the integration of advanced technologies in food processing is crucial for enhancing product shelf life and reducing waste (NIST, 2025).

In the meat processing sector, the ZKZB-125 is used to prepare ingredients for sausages, minced meat, and other processed meat products. The vacuum environment ensures that the meat retains its color and texture, which is essential for consumer appeal. Additionally, the machine's ability to kill bacteria through vacuum processing contributes to the overall safety of the product.

For pet food production, the ZKZB-125 offers similar benefits. The vacuum processing helps preserve the nutritional value of ingredients, ensuring that pets receive high-quality food. This is particularly important for manufacturers who are increasingly focusing on the health and wellness of pets, a growing trend in the pet care industry.

Company Background: Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

Hebei Yuanchang Food Mechanism & Technology Co., Ltd. is a leading manufacturer of food processing equipment, specializing in innovative solutions for the meat and pet food industries. With a commitment to quality and customer satisfaction, the company has established itself as a trusted name in the field. Their products are designed to meet the highest standards of performance, safety, and efficiency.

The company's focus on research and development has enabled it to create cutting-edge machinery like the ZKZB-125. By staying ahead of industry trends and continuously improving their products, Hebei Yuanchang ensures that their customers have access to the latest advancements in food processing technology. This dedication to innovation is reflected in the company's reputation for delivering reliable and high-performance equipment.

Authoritative References and Standards

The importance of precise measurements and advanced technologies in food processing is underscored by the work of the National Institute of Standards and Technology (NIST). According to NIST, the development of standards and measurement techniques is essential for ensuring the safety and quality of food products (NIST, 2025). The Vacuum Bowl Cutter ZKZB-125 aligns with these principles by incorporating vacuum technology to enhance product quality and safety.

Furthermore, the integration of vacuum processing in food equipment is supported by industry research highlighting its benefits in preserving product integrity. As the food processing industry continues to evolve, the adoption of such technologies is crucial for meeting consumer expectations and regulatory requirements.

Conclusion

The Vacuum Bowl Cutter ZKZB-125 is a testament to the advancements in food processing technology, offering a reliable solution for meat and pet food manufacturers. With its vacuum processing capabilities, user-friendly design, and versatile applications, the ZKZB-125 sets a new standard for efficiency and quality in the industry. Hebei Yuanchang Food Mechanism & Technology Co., Ltd. continues to innovate, ensuring that their products meet the highest standards of performance and safety.

For more information about the ZKZB-125 and other products from Hebei Yuanchang, visit their official website here.