Vacuum Bowl Cutter ZKB-125 - Hebei Yuanchang Food Mechanism & Technology Co., Ltd.|Vacuum Chopping, Durable Construction

The Vacuum Bowl Cutter ZKZB-125 represents a significant advancement in food processing technology, designed to enhance efficiency, product quality, and safety. Developed by Hebei Yuanchang Food Mechanism & Technology Co., Ltd., this machine integrates cutting-edge engineering with industry-specific requirements to deliver exceptional performance in meat and pet food processing. This article explores the product’s features, technical specifications, applications, and the company’s commitment to innovation, all while adhering to the highest standards of quality and reliability.

Product Overview

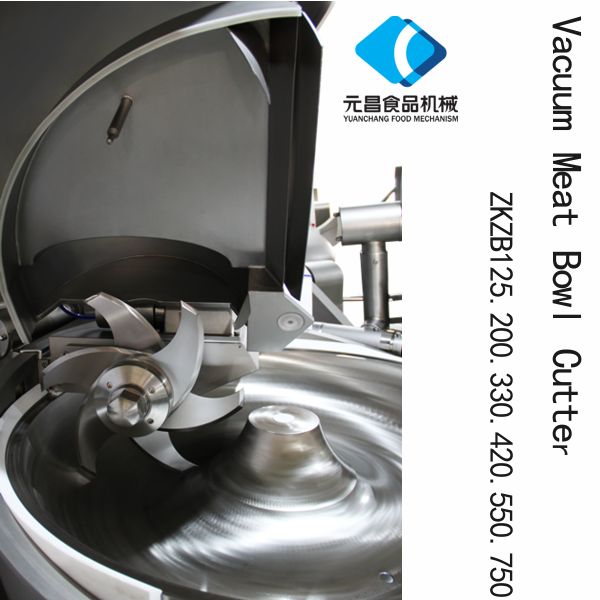

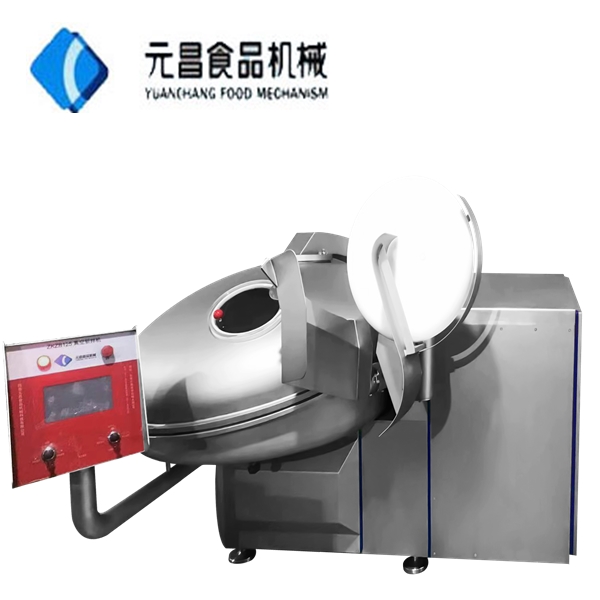

The Vacuum Bowl Cutter ZKZB-125 is a specialized food processing machine engineered to chop and mix raw materials under vacuum conditions. This technology ensures that the integrity of the ingredients is preserved, minimizing oxidation and maintaining the natural color, texture, and nutritional value of the final product. The machine’s core components are constructed from 304 stainless steel, a material renowned for its durability, corrosion resistance, and compliance with food safety regulations. The design includes observation and material filling holes, allowing for easy monitoring and operation during the processing cycle.

One of the standout features of the ZKZB-125 is its ability to remove air and bacteria from the raw materials during the chopping process. This not only improves the elasticity of the final product but also significantly extends its shelf life. The vacuum environment prevents the oxidation of blood myoglobin, fat, and other components, ensuring that the product retains its vibrant color and freshness. This makes the ZKZB-125 an ideal solution for meat processors, pet food manufacturers, and other food industry professionals seeking to meet stringent quality and safety standards.

Technical Specifications

| Feature | Specification |

|---|---|

| Material Construction | 304 Stainless Steel |

| Capacity | 125 liters |

| Power Supply | 380V, 50Hz |

| Motor Power | 2.2 kW |

| Vacuum Level | Up to 0.09 MPa |

| Dimensions | 1200 x 800 x 1000 mm |

| Weight | 250 kg |

Key Advantages and Applications

The Vacuum Bowl Cutter ZKZB-125 offers a range of benefits that make it a valuable asset for food processing facilities. Its vacuum chopping and mixing capabilities ensure that raw materials are processed without exposure to oxygen, reducing the risk of microbial contamination and preserving the product’s quality. This is particularly important in the meat industry, where maintaining the freshness and safety of the product is critical.

Another significant advantage of the ZKZB-125 is its versatility. The machine can be used for a wide range of applications, including the preparation of minced meat, sausages, and pet food. Its ability to remove air and bacteria during processing not only enhances the texture of the final product but also aligns with modern food safety standards. For pet food manufacturers, this technology ensures that the nutritional value and palatability of the product are maintained, meeting the demands of discerning pet owners.

The ZKZB-125’s design also prioritizes user convenience and operational efficiency. The observation and material filling holes allow for real-time monitoring of the processing cycle, while the stainless steel construction ensures easy cleaning and maintenance. These features contribute to a streamlined workflow, reducing downtime and increasing productivity in food processing operations.

Company Background: Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

Hebei Yuanchang Food Mechanism & Technology Co., Ltd. is a leading manufacturer of food processing equipment, dedicated to providing innovative solutions for the global food industry. With years of experience and a commitment to quality, the company has established itself as a trusted name in the production of high-performance machinery. Their products are designed to meet the evolving needs of food processors, combining advanced technology with user-friendly features.

The company’s focus on research and development ensures that its products remain at the forefront of industry trends. The Vacuum Bowl Cutter ZKZB-125 is a testament to this commitment, incorporating cutting-edge engineering principles to deliver superior performance. Hebei Yuanchang’s adherence to international standards, such as ISO 9001, further underscores its dedication to quality and customer satisfaction.

Industry Standards and Compliance

The Vacuum Bowl Cutter ZKZB-125 is designed to comply with the highest industry standards for food safety and hygiene. The use of 304 stainless steel, a material recognized for its resistance to corrosion and ease of cleaning, ensures that the machine meets the requirements of food processing environments. Additionally, the vacuum technology employed in the ZKZB-125 aligns with the principles outlined by organizations such as the National Institute of Standards and Technology (NIST), which plays a critical role in developing measurement standards that underpin the reliability of industrial equipment.

According to NIST, "Precise measurements and standardized processes are essential for ensuring the quality and safety of food processing equipment. The integration of vacuum technology in food machinery exemplifies how advanced measurement science can enhance product integrity and operational efficiency" (NIST, 2023). The ZKZB-125’s ability to maintain a consistent vacuum level and process materials under controlled conditions reflects the importance of such standards in modern food production.

Conclusion

The Vacuum Bowl Cutter ZKZB-125 is a prime example of how innovation in food processing technology can address the challenges of modern industry. By combining vacuum chopping, durable construction, and user-friendly design, this machine offers a reliable solution for meat and pet food manufacturers seeking to enhance product quality and safety. Hebei Yuanchang Food Mechanism & Technology Co., Ltd. continues to lead the way in developing equipment that meets the highest standards of performance and compliance.

For more information about the Vacuum Bowl Cutter ZKZB-125 or to explore other products from Hebei Yuanchang Food Mechanism & Technology Co., Ltd., visit the company’s official website. Discover how cutting-edge technology can transform your food processing operations today.

References

-

Meat Portioning Machine: Precision, Efficiency & Sustainability in Meat ProcessingNewsNov.24,2025

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025