Vacuum Bowl Cutter for Meat Processing - Hebei Yuanchang | Meat Processing&Pet Food Production

The Vacuum Bowl Cutter ZKZB-125 is a cutting-edge solution designed to revolutionize the meat processing industry. Developed by Hebei Yuanchang Food Mechanism & Technology Co., Ltd., this machine combines advanced engineering with practical functionality to enhance efficiency and product quality. Whether you're processing meat for human consumption or pet food, the ZKZB-125 offers unparalleled performance. Below, we explore its features, advantages, technical specifications, application scenarios, and the company behind this innovation.

Key Features of the ZKZB-125

The ZKZB-125 is engineered with precision to meet the demands of modern food processing. Its core construction is made from 304 stainless steel, a material renowned for its durability, resistance to corrosion, and compliance with food safety standards. This ensures the machine can withstand rigorous use while maintaining hygiene. The design includes observation holes and material filling holes, allowing operators to monitor the process and add ingredients seamlessly. These features are critical for maintaining consistent quality and operational efficiency.

One of the standout features of the ZKZB-125 is its vacuum operation system. By chopping and mixing raw materials under vacuum, the machine prevents oxidation, preserving the blood myoglobin, fat, and other vital components of the meat. This process not only retains the vibrant color of the product but also enhances its texture and shelf life. Additionally, the removal of air during processing helps eliminate bacteria, contributing to a safer and longer-lasting final product.

The ZKZB-125 is also versatile, as it can be used for pet food processing. This dual-purpose capability makes it an attractive investment for businesses looking to diversify their offerings. The machine’s design ensures that it can handle a wide range of ingredients, from lean meats to more complex formulations, without compromising performance.

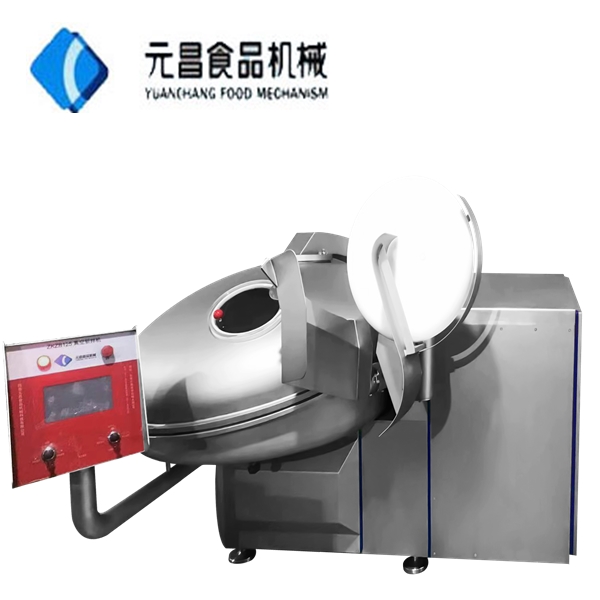

Photo: The ZKZB-125's stainless steel construction and vacuum system ensure durability and hygiene in meat processing.

Advantages of the ZKZB-125

The ZKZB-125 offers several advantages that set it apart from traditional meat processing equipment. One of the primary benefits is its ability to preserve product quality. By operating under vacuum, the machine minimizes the risk of oxidation, which can degrade the color, flavor, and nutritional value of meat. This is particularly important for products that require a long shelf life, such as sausages, ground meats, and pet food.

Another significant advantage is the increased elasticity of the processed meat. The vacuum environment helps retain moisture and natural juices, resulting in a more tender and flavorful product. This is especially beneficial for applications where texture is critical, such as in premium meat products or specialty pet foods.

The ZKZB-125 also contributes to food safety. The removal of air during the chopping process reduces the presence of oxygen, which is a key factor in bacterial growth. This not only extends the shelf life of the product but also ensures compliance with food safety regulations. For businesses, this means fewer waste incidents and a more reliable supply chain.

Operational efficiency is another key advantage. The machine’s user-friendly design allows for quick setup and easy maintenance, reducing downtime and increasing productivity. The observation and filling holes enable real-time monitoring, ensuring that operators can adjust the process as needed without interrupting the workflow.

Photo: The ZKZB-125's vacuum system ensures optimal processing conditions for meat and pet food.

Technical Specifications

To provide a comprehensive overview, here is a detailed table of the ZKZB-125’s technical specifications:

| Parameter | Details |

|---|---|

| Model | ZKZB-125 |

| Material Construction | 304 Stainless Steel |

| Capacity | 125 liters |

| Power Supply | 380V, 50Hz |

| Motor Power | 1.5 kW |

| Operating Pressure | Vacuum (up to -0.09 MPa) |

| Dimensions | 1200 x 800 x 1000 mm |

| Weight | 250 kg |

| Control System | Manual and Automatic Options |

| Additional Features | Observation Holes, Material Filling Holes, Safety Guards |

Application Scenarios

The ZKZB-125 is designed for a wide range of applications, making it a versatile asset for food processing facilities. Its primary use is in meat processing, where it excels at chopping, mixing, and emulsifying raw ingredients. This makes it ideal for producing ground meats, sausages, and other processed meat products. The vacuum environment ensures that the final product retains its freshness, color, and texture, which is essential for high-quality offerings.

In addition to meat processing, the ZKZB-125 is also suitable for pet food production. Pet food manufacturers can utilize this machine to create nutritious and appealing formulations for dogs and cats. The ability to process a variety of ingredients, including meats, vegetables, and grains, allows for the creation of customized pet food blends. This flexibility is a significant advantage for businesses aiming to cater to niche markets or specific dietary needs.

The machine’s design also makes it suitable for small to medium-sized operations. Its compact size and efficient operation allow it to fit into existing production lines without requiring extensive modifications. For businesses looking to scale up their operations, the ZKZB-125 provides a reliable and cost-effective solution that can handle increasing production demands.

Photo: The ZKZB-125's vacuum system ensures optimal processing conditions for meat and pet food.

About Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

Hebei Yuanchang Food Mechanism & Technology Co., Ltd. is a leading manufacturer of food processing equipment, specializing in innovative solutions for the meat and pet food industries. With years of experience and a commitment to quality, the company has established itself as a trusted name in the field. Their products are designed to meet the highest standards of performance, safety, and efficiency.

The company’s focus on research and development ensures that their machines incorporate the latest advancements in food processing technology. This dedication to innovation is evident in the ZKZB-125, which combines traditional craftsmanship with modern engineering. Hebei Yuanchang’s products are used by businesses worldwide, helping them achieve greater productivity and product quality.

Hebei Yuanchang is also committed to sustainability and environmental responsibility. Their manufacturing processes are designed to minimize waste and reduce energy consumption, aligning with global efforts to promote eco-friendly practices in the food industry. This commitment to sustainability not only benefits the environment but also helps businesses reduce their operational costs in the long run.

For more information about Hebei Yuanchang Food Mechanism & Technology Co., Ltd., visit their official website: Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

Why Choose the ZKZB-125?

The ZKZB-125 stands out as a reliable and efficient solution for meat and pet food processing. Its vacuum technology ensures that products retain their quality, while its stainless steel construction guarantees durability and hygiene. The machine’s versatility allows it to handle a wide range of ingredients, making it suitable for various applications. Additionally, its user-friendly design and easy maintenance contribute to operational efficiency, reducing downtime and increasing productivity.

For businesses looking to invest in a high-quality processing machine, the ZKZB-125 offers a cost-effective solution that delivers long-term value. Its ability to enhance product quality, ensure food safety, and improve operational efficiency makes it an excellent choice for both small and large-scale operations. By choosing the ZKZB-125, businesses can stay competitive in a rapidly evolving market.

References

1. National Institute of Standards and Technology (NIST). (n.d.). Driving Innovation. Retrieved from https://www.nist.gov. NIST plays a crucial role in advancing technology through precise measurements and research, which are essential for industries like food processing.

2. National Institute of Standards and Technology (NIST). (n.d.). What we do. Retrieved from https://www.nist.gov. NIST’s work in standards and measurements supports innovation and improves the quality of life for all Americans.

3. National Institute of Standards and Technology (NIST). (n.d.). Standards. Retrieved from https://www.nist.gov. NIST provides critical standards that ensure the reliability and safety of industrial equipment, including food processing machinery.

For more details about the Vacuum Bowl Cutter ZKZB-125, visit the product page: Vacuum Bowl Cutter ZKZB-125.

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025

-

Best Commercial Marinating Machines for Meat Processing | Efficient & ScalableNewsNov.20,2025