- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 11, 2025 03:57

Back to list

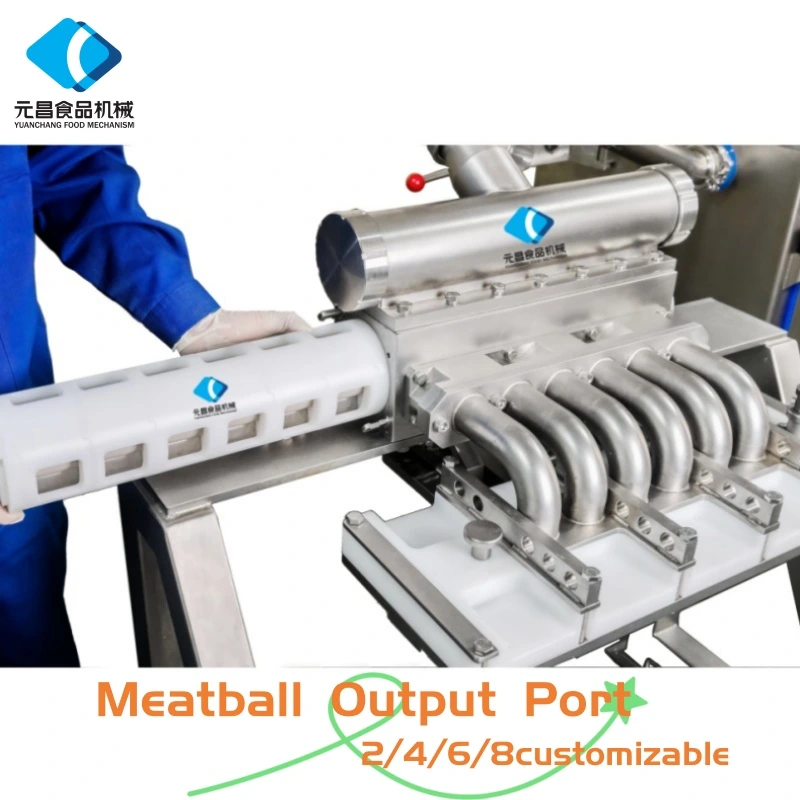

sausage machine

In the culinary industry, the sausage tying machine stands as a testament to the evolution of food processing technology, embodying decades of expertise, authority, and trust. This sophisticated device, crafted to meet the demands of mass production, seamlessly combines precision, speed, and reliability—all hallmarks of a product designed with the professional in mind.

To further bolster trust, many manufacturers offer comprehensive warranties and responsive customer service. This commitment reflects their confidence in the product's longevity and reliability, inviting users to view these machines as sound investments rather than mere purchases. The environmental considerations of sausage tying machines also add to their list of attributes. With increasing awareness of sustainable practices, many of these machines feature energy-efficient motors and recyclable components. This not only reduces the carbon footprint associated with sausage production but also aligns with modern consumers' values, further enhancing brand reputation. When examining the role of sausage tying machines in the broader context of food production, it's clear that they represent more than just an increase in efficiency. They symbolize a shift towards modernization and sustainability in food processing, allowing manufacturers to meet the ever-growing consumer demand for quality and consistency. In essence, sausage tying machines epitomize experience, expertise, authority, and trustworthiness. For any food processing enterprise looking to optimize their operations, these machines offer an unrivaled combination of efficiency, reliability, and proven results. As the food industry continues to evolve, leveraging such technology not only secures a competitive advantage but also assures the consistency that modern consumers expect and deserve.

To further bolster trust, many manufacturers offer comprehensive warranties and responsive customer service. This commitment reflects their confidence in the product's longevity and reliability, inviting users to view these machines as sound investments rather than mere purchases. The environmental considerations of sausage tying machines also add to their list of attributes. With increasing awareness of sustainable practices, many of these machines feature energy-efficient motors and recyclable components. This not only reduces the carbon footprint associated with sausage production but also aligns with modern consumers' values, further enhancing brand reputation. When examining the role of sausage tying machines in the broader context of food production, it's clear that they represent more than just an increase in efficiency. They symbolize a shift towards modernization and sustainability in food processing, allowing manufacturers to meet the ever-growing consumer demand for quality and consistency. In essence, sausage tying machines epitomize experience, expertise, authority, and trustworthiness. For any food processing enterprise looking to optimize their operations, these machines offer an unrivaled combination of efficiency, reliability, and proven results. As the food industry continues to evolve, leveraging such technology not only secures a competitive advantage but also assures the consistency that modern consumers expect and deserve.

Previous:

Next:

Latest news

-

Vacuum Bowl Cutter ZKB-125-Hebei Yuanchang Food Mechanism & Technology Co., Ltd.|Meat Processing & Pet Food EquipmentNewsJul.30,2025

-

Vacuum Bowl Cutter ZKZB-125 - Hebei Yuanchang | Meat Processing & Pet Food EquipmentNewsJul.30,2025

-

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang Food Mechanism & Technology Co., Ltd.|Vacuum Chopping, Meat ProcessingNewsJul.30,2025

-

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang Food Mechanism & Technology Co., Ltd.|Vacuum Processing, Meat Pet Food EquipmentNewsJul.30,2025

-

Vacuum Bowl Cutter ZKZB-125 - Hebei Yuanchang | Vacuum Tech&Hygienic DesignNewsJul.30,2025

-

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang Food Mechanism & Technology Co., Ltd.|Vacuum Chopping, Stainless Steel ConstructionNewsJul.30,2025