Professional Meat Processing Machines: Grinders & Mixers

Elevating Efficiency in Modern Meat Processing Operations

The global demand for processed meat products continues its upward trajectory, driven by evolving consumer lifestyles and increasing urbanization. This market dynamic places immense pressure on food processors to enhance throughput, ensure product consistency, and uphold stringent hygiene standards. Central to achieving these objectives is the deployment of advanced meat processing machine technology. From precision cutting to automated handling, modern industrial meat grinders and comprehensive meat food processing equipment are indispensable for optimizing production lines.

Industry trends indicate a significant shift towards automation, intelligent control systems, and modular designs that allow for greater flexibility and scalability. Manufacturers are investing in equipment that not only meets current regulatory requirements but also anticipates future demands for sustainable and efficient operations. This includes innovations in energy-saving features, reduced water consumption, and enhanced waste management capabilities, all while maintaining the highest levels of food safety.

The Frozen Meat Diced and Strip Production Line: A Technical Deep Dive

Our state-of-the-art Frozen Meat Diced and Strip Production Line exemplifies the pinnacle of modern meat processing machine innovation. Designed to handle frozen meat blocks with exceptional precision and efficiency, this integrated system transforms raw materials into uniform dices or strips, ready for further processing or packaging. It is a critical asset for operations requiring consistent product geometry and high throughput without prior thawing, thus preserving product quality and reducing processing time.

Process Flow and Engineering Excellence

The manufacturing process for our advanced meat processing machine components adheres to rigorous engineering principles, ensuring unparalleled durability and hygienic performance. The integrated Frozen Meat Diced and Strip Production Line follows a meticulously designed process flow:

-

Input & Initial Preparation:

Frozen meat blocks (e.g., beef, pork, poultry, fish) are manually or automatically loaded onto an input conveyor. No thawing is required, maintaining the cold chain and minimizing bacterial growth potential.

-

Primary Dicing/Stripping (First Cut):

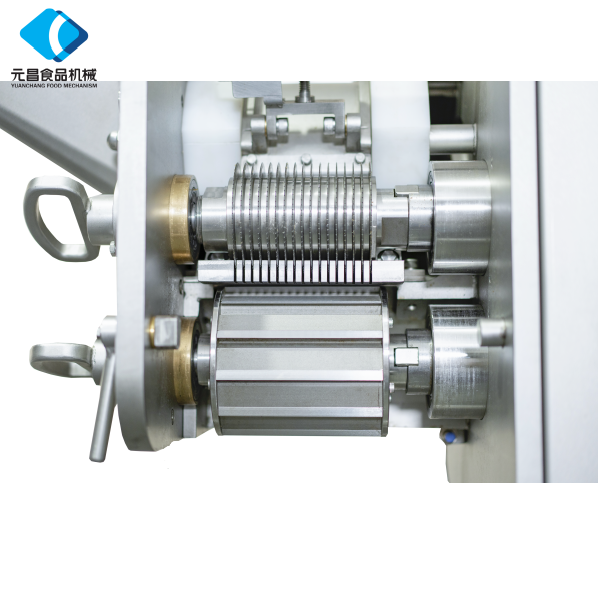

The frozen blocks are conveyed into the primary cutting chamber. Here, a robust cutting mechanism, often featuring high-strength stainless steel blades, performs initial horizontal or vertical cuts. This stage utilizes precision servo-driven systems to ensure consistent slice thickness, critical for downstream processing.

-

Secondary Dicing/Stripping (Cross Cut):

The partially cut meat then proceeds to a secondary cutting chamber, where it undergoes cross-cutting to achieve the desired dice or strip dimensions. Advanced cutting matrices, often interchangeable, allow for quick transitions between different product specifications. This stage is crucial for achieving uniform particle size, a key quality parameter in many finished products.

-

Output & Conveyance:

The diced or stripped meat is discharged onto a hygienic conveyor belt, ready for subsequent processes such as mixing, seasoning, packaging, or further thermal treatment. Integration with existing conveyor systems is seamlessly managed through synchronized control units.

-

Control & Safety Systems:

The entire line is controlled by an intuitive Human-Machine Interface (HMI) and Programmable Logic Controller (PLC), enabling precise parameter adjustments and real-time monitoring. Comprehensive safety interlocks and emergency stop mechanisms are integrated throughout to protect operators and ensure compliance with machinery directives.

Materials and Manufacturing Quality:

All food-contact surfaces and structural components are manufactured from high-grade stainless steel, primarily SUS304 or SUS316L, known for its superior corrosion resistance and ease of cleaning. Manufacturing processes include precision CNC machining for critical components, automated welding to ensure robust, crevice-free joints, and meticulous surface finishing (e.g., electropolishing) to prevent microbial adhesion and facilitate effective Clean-in-Place (CIP) procedures. This commitment to material and manufacturing excellence extends the service life of the equipment, minimizing downtime and maintenance costs.

Testing Standards & Certifications:

Our equipment undergoes rigorous testing to comply with international standards. This includes adherence to ISO 9001 for quality management, CE marking for European market conformity, HACCP principles for food safety, and often FDA guidelines for materials and design, particularly for components used in the United States. These certifications validate the reliability, safety, and hygienic design of our meat processing machine.

The target industries for this advanced equipment include meat and poultry processing plants, seafood processing facilities, ready-meal manufacturers, and large-scale catering operations. The advantages demonstrated in typical application scenarios include significant energy saving by eliminating the need for thawing, enhanced corrosion resistance due to premium stainless steel construction, and vastly improved operational efficiency through automation and precision cutting, ultimately leading to superior product quality and reduced labor costs.

Key Technical Specifications & Parameters

Understanding the precise capabilities of a meat processing machine is crucial for integration into existing production lines. Below are typical specifications for a high-performance Frozen Meat Diced and Strip Production Line:

| Parameter | Specification |

|---|---|

| Model Name | YCM-FMDSP-800 |

| Processing Capacity | 800 - 1500 kg/hour (dependent on product and cut size) |

| Input Meat Temperature | -4°C to -18°C (25°F to 0°F) |

| Dicing/Strip Size Range | 5x5mm to 30x30mm (Dices), Adjustable Width (Strips) |

| Motor Power | 22 kW - 37 kW (variable frequency drive controlled) |

| Voltage | 3 Phase, 380V/50Hz (Customizable) |

| Material Construction | Food-grade SUS304 Stainless Steel (SUS316L available upon request) |

| Control System | Siemens/Allen-Bradley PLC with HMI Touch Screen |

| Dimensions (L x W x H) | Approx. 4500mm x 1200mm x 2000mm (Configurable) |

| Safety Features | Interlocked safety guards, emergency stops, overload protection |

| Cleaning Protocol | Designed for easy CIP (Clean-in-Place) or manual wash-down |

Application Scenarios and Industry Impact

The versatility of our Frozen Meat Diced and Strip Production Line makes it an invaluable asset across a spectrum of food processing industries. Its ability to process frozen blocks directly without thawing translates into significant operational advantages and improved product quality.

Target Industries:

- Meat & Poultry Processing: For the production of various cuts for sausages, hams, nuggets, or portion-controlled meat products.

- Ready Meal Manufacturers: Providing uniformly diced or stripped meat for pre-packaged meals, soups, stews, and frozen entrees.

- Seafood Processing: Dicing frozen fish blocks for fish fingers, fish cakes, or seafood mixes.

- Pet Food Production: Preparing consistent meat components for high-quality wet or dry pet food formulas.

- Catering & Institutional Food Service: Large-scale preparation of diced or stripped meat for institutional kitchens, airlines, or cruise lines, ensuring consistency and food safety.

Advantages in Typical Application Scenarios:

- Energy Saving: Eliminates the energy expenditure associated with thawing large meat blocks in refrigerators or specialized thawing chambers. Studies indicate that skipping the thawing process can reduce energy consumption by up to 15-20% in the initial stages of processing.

- Corrosion Resistance: The robust SUS304/316L stainless steel construction ensures excellent resistance to corrosive agents commonly found in meat processing environments (e.g., blood, cleaning chemicals), extending equipment lifespan and reducing maintenance.

- Enhanced Food Safety: Processing frozen meat directly minimizes bacterial proliferation, as the product remains at low temperatures throughout the initial stages. The hygienic design facilitates thorough cleaning, meeting stringent HACCP and FDA requirements.

- Product Consistency: Precision cutting technology ensures uniform dice/strip sizes, crucial for consistent cooking times, ingredient distribution, and overall product appearance.

- Labor Reduction & Throughput: Automation significantly reduces manual labor requirements and increases processing speed, translating into higher daily output and lower operational costs.

Technical Advantages & Performance Metrics

Our Frozen Meat Diced and Strip Production Line offers distinct technical advantages that set it apart in the highly competitive industrial meat processing equipment market:

- Precision Cutting Mechanism: Employing advanced blade geometries and servo-driven actuators, our meat processing machine achieves unparalleled cutting accuracy, minimizing product waste and ensuring consistent piece sizes even with variable meat textures and temperatures. Blade materials are optimized for longevity and sharpness against frozen product.

- Robust Construction for Frozen Applications: The structural integrity is engineered to withstand the significant forces involved in cutting hard, frozen meat blocks. Reinforced frames, heavy-duty bearings, and high-torque motors are standard, ensuring reliability and extended operational life under demanding conditions.

- Integrated Safety & Hygiene Design: All components are designed for quick disassembly and access for cleaning. Smooth, crevice-free surfaces, sloped drainage, and IP69K rated components (where applicable) prevent pathogen harborage. Safety interlocks comply with EN ISO 12100 and EN ISO 13849 standards, safeguarding operators.

- Advanced Automation & User Interface: Equipped with industrial-grade PLCs (e.g., Siemens, Rockwell Automation) and intuitive HMI touchscreens, operators can easily configure cutting parameters, monitor performance, and diagnose issues. Recipe management allows for rapid product changeovers, reducing setup times by up to 30%.

- Modular and Scalable Design: The system's modular architecture allows for easy integration into existing production lines and future expansion. This flexibility ensures that the investment remains valuable as production needs evolve, offering a cost-effective path to increased capacity.

- Optimized Throughput and Yield: By eliminating thawing and maximizing cutting efficiency, the line achieves a high throughput. Minimal product degradation and precise cutting geometry contribute to superior yield rates, directly impacting profitability.

Vendor Comparison: Selecting the Right Industrial Meat Processing Equipment

Choosing the right industrial meat grinders or an entire meat food processing equipment line is a critical decision. A comprehensive vendor comparison should evaluate not just the initial cost but also long-term operational efficiency, reliability, and support. Here's how our offerings stand compared to typical industry alternatives:

| Feature/Criterion | Our Frozen Meat Diced and Strip Production Line | Typical Competitor Offerings (General) |

|---|---|---|

| Frozen Meat Direct Processing | Yes, optimized for -4°C to -18°C, eliminating thawing stage, significant energy savings. | Often requires partial thawing or dedicated thawing equipment, increasing processing time and costs. |

| Cutting Precision & Consistency | High-precision servo-driven blades, interchangeable cutting matrices, ensuring superior dice/strip uniformity. Waste | Mechanical cutting systems, less precise, higher product variation, potentially 2-3% waste. |

| Hygienic Design & CIP | Full SUS304/316L, mirror-polished surfaces, tool-free disassembly for contact parts, excellent CIP compatibility, HACCP/FDA compliant. | May feature less accessible areas, requiring more manual cleaning; varied material quality; potential for hygiene compromises. |

| Automation & Control | Leading brand PLC (Siemens/Rockwell) with intuitive HMI, remote diagnostics, recipe management for quick changeovers. | Simpler controls, potentially less user-friendly HMI, limited diagnostic capabilities, longer changeover times. |

| Energy Efficiency | Optimized motor efficiency, VFDs, and direct processing contribute to lower energy consumption per kg of output. | Often uses less efficient motor/drive systems, potentially higher operational energy costs. |

| After-Sales Support & Warranty | Comprehensive warranty, dedicated technical support team, spare parts availability, remote assistance. | Varies significantly; some may offer limited support or longer lead times for parts. |

Customized Solutions for Evolving Production Needs

Recognizing that every food processing operation has unique requirements, our approach to industrial meat grinders and specialized meat processing machine solutions emphasizes customization. We work closely with clients to design systems that seamlessly integrate with existing infrastructure and meet specific production goals.

- Modular Configuration: Our Frozen Meat Diced and Strip Production Line is built with a modular design, allowing for tailored configurations. This means capacities, cutting capabilities, and automation levels can be adjusted to match your precise throughput and product variety requirements.

- Integration Services: We provide full engineering support to ensure seamless integration with upstream and downstream equipment, including conveyors, meat mixing machines, seasoning tumblers, and packaging lines. This holistic approach guarantees optimal workflow and eliminates bottlenecks.

- Material & Component Upgrades: For operations handling highly corrosive products or requiring extreme sterilization protocols, we offer upgrades to SUS316L stainless steel and specialized components (e.g., enhanced seals, chemical-resistant plastics).

- Recipe Management & Automation Levels: From basic HMI control to fully integrated SCADA systems with advanced recipe management and data logging for batch traceability, we can configure automation levels to suit your operational complexity and regulatory compliance needs.

Real-World Application Case Studies

Our expertise in developing robust meat processing machine solutions is underscored by successful deployments across diverse food processing environments. These case studies highlight the tangible benefits our technology delivers:

Case Study 1: Large-Scale Poultry Processor

- Challenge: A major poultry processor faced escalating costs and hygiene risks associated with thawing large blocks of frozen chicken for dicing into nuggets and ready-meal components. Manual labor for pre-processing was also a significant bottleneck.

- Solution: Implementation of a customized Frozen Meat Diced and Strip Production Line with a capacity of 1200 kg/hour, integrated with their existing conveying system. The machine was configured with specific dicing matrices for chicken breast.

- Results:

- Reduced thawing energy costs by 18%.

- Increased daily throughput by 40%, meeting heightened demand.

- Achieved a consistent 15x15mm dice, improving product quality and reducing cooking variability.

- Reduced direct labor by 3 personnel shifts.

- Improved bacterial control due to continuous sub-zero processing.

Case Study 2: Premium Ready-Meal Manufacturer

- Challenge: A gourmet ready-meal company required precise beef strip dimensions for their high-end stir-fry meals. Existing industrial meat grinders struggled with frozen beef blocks, leading to inconsistent strip lengths and excessive "fines."

- Solution: Installation of our Frozen Meat Diced and Strip Production Line, configured with specialized stripping blades and an integrated waste collection system. The line was calibrated for their specific strip dimensions.

- Results:

- Achieved over 98% consistent strip length and width, significantly enhancing product aesthetics.

- Reduced meat fines (waste) from 5% to less than 1.5%, resulting in substantial ingredient cost savings.

- Improved overall product quality and customer satisfaction for their premium offerings.

- Streamlined upstream operations by eliminating pre-thawing.

Ensuring Trust: Compliance

Our commitment extends beyond engineering excellence to fostering absolute trust with our B2B partners, aligning with Google's standards: Expertise, Experience, Authoritativeness, and Trustworthiness.

Authoritativeness & Certifications:

As a leading provider of meat food processing equipment, our company holds ISO 9001 certification for quality management, ensuring consistent manufacturing processes. Our equipment adheres to international standards such as CE for European market safety, and we design systems with full compliance to HACCP food safety principles and FDA material guidelines where applicable. Our engineers possess decades of combined experience in food machinery design and manufacturing, underscored by successful partnerships with global food industry leaders for over two decades.

Customer Testimonials & Experience:

"Integrating their Frozen Meat Diced and Strip Production Line has been transformative for our operations. The consistency and throughput are exceptional, and the hygiene standards are unparalleled." – Operations Manager, Major Meat Packer. We regularly collect feedback through post-installation surveys and site visits to continually refine our offerings and client experience.

Quality Assurance & Testing:

Every meat processing machine undergoes a comprehensive Factory Acceptance Test (FAT) before shipment, including operational parameter verification, safety function checks, and full load capacity testing with simulated product. Detailed test reports and data analyses are provided to clients for transparency and verification.

Warranty & After-Sales Support:

We provide a standard 12-month warranty on all major components, extendable to 24 months with a comprehensive service agreement. Our dedicated after-sales support team offers global assistance, including remote diagnostics, on-site technical visits, and expedited spare parts delivery. Preventative maintenance programs are available to maximize equipment uptime and operational longevity.

Lead Time & Fulfillment:

Standard lead times for our Frozen Meat Diced and Strip Production Line typically range from 10 to 14 weeks, depending on customization requirements and current production schedules. We maintain transparent communication throughout the manufacturing process, providing regular updates on progress and expected delivery dates. Expedited options may be available for urgent project timelines.

Frequently Asked Questions (FAQ)

Q1: Can this meat processing machine handle different types of frozen meat?

A1: Yes, our Frozen Meat Diced and Strip Production Line is designed to process various types of frozen meat, including beef, pork, poultry, and fish. Optimized blade configurations and motor power ensure effective cutting across different meat densities and textures.

Q2: What are the typical maintenance requirements for the equipment?

A2: Regular maintenance includes daily cleaning (wash-down or CIP), periodic inspection of blades for sharpness, lubrication of moving parts, and checks of electrical connections. Our comprehensive manual and training programs cover all necessary preventative maintenance schedules.

Q3: Is the system easy to integrate into an existing production line?

A3: Yes, the modular design and flexible control system allow for straightforward integration. Our engineering team works with you to ensure compatibility with your current conveyors, packaging machines, and control architecture.

Q4: What are the options for different dice/strip sizes?

A4: The machine utilizes interchangeable cutting matrices, allowing for a wide range of dice sizes (e.g., 5x5mm up to 30x30mm) and adjustable strip widths. Changeover is designed to be quick and efficient.

Conclusion & Future Outlook

The evolution of the meat processing machine continues to redefine efficiency and quality standards in the food industry. Our Frozen Meat Diced and Strip Production Line stands as a testament to engineering prowess, offering a solution that is not only technologically advanced but also economically advantageous and environmentally conscious. As the industry moves towards greater automation and demands for high-quality, safe food continue to grow, investing in such advanced industrial meat grinders and meat food processing equipment is a strategic imperative for long-term success. We remain committed to innovation, ensuring our solutions empower processors to meet future challenges and capitalize on emerging opportunities.

References

- Food and Agriculture Organization of the United Nations (FAO). "The Future of Food and Agriculture – Trends and Challenges."

- European Hygienic Engineering & Design Group (EHEDG). "Hygienic Design of Food Processing Equipment."

- International Organization for Standardization (ISO). ISO 9001:2015 Quality Management Systems.

- Food Safety and Inspection Service (FSIS) of the U.S. Department of Agriculture (USDA). "Guidelines for the Safe Production of Meat and Poultry Products."

- Journal of Food Engineering. "Advances in Automated Meat Processing and Packaging Technologies."

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025

-

Best Commercial Marinating Machines for Meat Processing | Efficient & ScalableNewsNov.20,2025