Premium Meat Processing Equipment: Cut, Grind, & Link Faster

Industry Trends and Market Dynamics in Meat Processing

The global food processing sector is undergoing a profound transformation, driven by escalating consumer demand for convenience, safety, and quality. Within this landscape, the meat processing equipment market is experiencing significant growth, projected to reach over USD 20 billion by 2027, according to recent industry analyses. This expansion is fueled by advancements in automation, an increasing focus on hygiene and food safety standards (such as HACCP and FDA regulations), and the rising need for operational efficiency in commercial slaughterhouses, butcheries, and food preparation facilities.

Key trends include the integration of IoT for predictive maintenance, enhanced data analytics for yield optimization, and the development of modular, flexible systems capable of handling diverse product lines. Furthermore, sustainability initiatives are driving demand for energy-efficient machinery with reduced water consumption, aligning with environmental responsibility goals across the supply chain. Manufacturers are continuously innovating to deliver solutions that not only boost productivity but also ensure stringent quality control and minimize human error, crucial factors in today's competitive market.

Manufacturing Process Flow of Advanced Meat Processing Equipment

The production of high-performance meat processing equipment, such as a specialized meat cutting machine or a sophisticated sausage making machine, follows a stringent multi-stage manufacturing process designed to ensure durability, hygiene, and precision. This process adheres to international quality standards like ISO 9001 for quality management and ISO 22000 for food safety management systems.

Key Stages of Production:

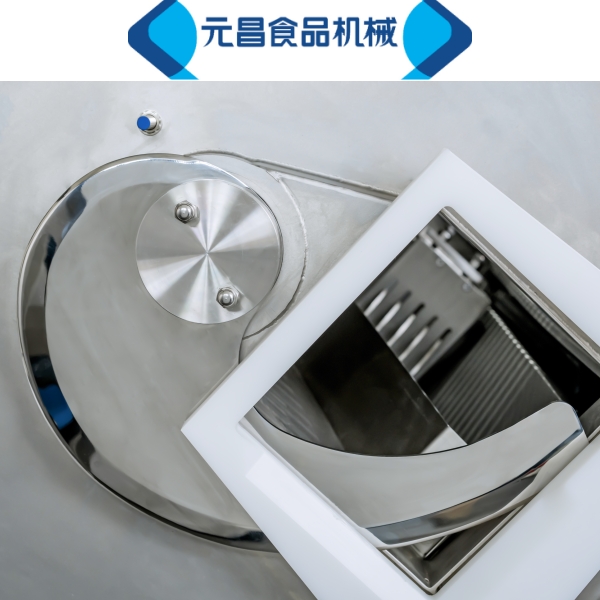

- Material Selection & Preparation: All contact parts are meticulously crafted from food-grade stainless steel (typically SUS304 or SUS316L) known for its exceptional corrosion resistance and ease of cleaning, crucial for preventing bacterial growth. Non-contact structural components may utilize high-strength alloys. Each batch of raw material undergoes rigorous chemical composition analysis to meet ASTM or EN standards.

- Precision Machining: Advanced CNC machining centers are employed for cutting, drilling, and shaping components with micron-level accuracy. Techniques like laser cutting for intricate parts and robotic welding for structural integrity ensure consistent quality and robust construction. For critical moving parts, processes such as forging or specialized heat treatments are applied to enhance hardness and wear resistance.

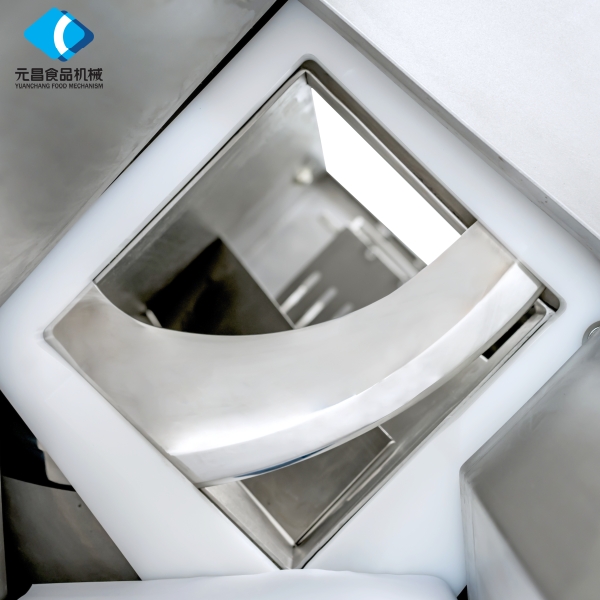

- Surface Treatment & Finishing: To achieve optimal hygiene and aesthetic appeal, components undergo passivation, electropolishing, or fine grinding. These processes eliminate microscopic surface imperfections, further enhancing corrosion resistance and making surfaces easier to sanitize.

- Assembly & Integration: Skilled technicians meticulously assemble the mechanical, electrical, and control systems. This stage involves integrating high-quality motors, sensors, PLCs, and human-machine interface (HMI) touchscreens, all sourced from reputable global suppliers.

- Rigorous Testing & Quality Assurance: Every piece of equipment undergoes a multi-point inspection and functional testing. This includes:

- Operational performance tests (e.g., cutting speed, precision, capacity).

- Safety feature verification (e.g., emergency stops, interlocks, guards).

- Endurance testing to simulate typical operating conditions for predicting service life (often exceeding 10-15 years with proper maintenance).

- Noise and vibration level assessment to comply with occupational safety standards.

- Hygiene inspection to ensure no crevices or difficult-to-clean areas exist.

- Certification & Documentation: Prior to dispatch, equipment receives necessary certifications (e.g., CE marking for European markets, USDA compliance for North America) and comprehensive documentation including operation manuals, maintenance guides, and spare parts lists.

Target Industries & Application Advantages:

Our meat processing equipment is specifically designed for a wide array of food industry applications. Typical scenarios demonstrate significant advantages:

- Energy Saving: Optimized motor designs and intelligent control systems minimize power consumption, offering up to 20% energy savings compared to conventional models, reducing operational costs for large-scale meat packers.

- Corrosion Resistance: The extensive use of SUS304/316L stainless steel ensures prolonged service life in harsh, moisture-rich environments typical of processing plants, reducing maintenance frequency and enhancing equipment longevity.

- Enhanced Hygiene: Smooth, crevice-free surfaces and tool-free disassembly features facilitate thorough cleaning and sanitation, meeting rigorous FDA and HACCP guidelines, thus safeguarding public health.

- Increased Throughput: High-speed, precision cutting, and forming capabilities dramatically increase production capacity, enabling facilities to meet fluctuating market demands efficiently.

Technical Specifications and Performance Parameters

Our range of meat processing equipment is engineered for optimal performance, combining robust construction with intelligent design. Below are typical specifications for a high-performance industrial cutting machine, representative of the precision and efficiency embedded in our products, including our renowned Cutting Rib Machine.

Product Specification Table: Cutting Rib Machine

| Parameter | Specification | Benefit / Feature |

|---|---|---|

| Model | YCM-CR1500 (Cutting Rib Machine) | Specialized for precision rib cutting. |

| Power Supply | 380V/50Hz/3-Phase (customizable) | Industrial standard, adaptable to regional grids. |

| Motor Power | 5.5 kW (High-efficiency IE3 rated) | Robust power for continuous, heavy-duty operation; energy-efficient. |

| Capacity | Up to 1500 kg/hour (pork ribs) | High throughput for large-scale production demands. |

| Cutting Thickness Range | 5 mm - 50 mm (adjustable) | Versatility for various product specifications. |

| Blade Material | German 440C Stainless Steel (HRC 58-60) | Exceptional sharpness retention and corrosion resistance. |

| Dimensions (L x W x H) | 2000 x 850 x 1350 mm | Optimized footprint for industrial settings. |

| Weight | Approx. 750 kg | Heavy-duty construction for stability and vibration reduction. |

| Safety Features | Emergency stop, safety interlocks on covers, overload protection. | Ensures operator safety and compliance with EN ISO 12100. |

| Control System | Siemens PLC with HMI Touchscreen | Intuitive operation, precise control, diagnostic capabilities. |

Application Scenarios and Technical Advantages

Our specialized meat processing equipment is critical across various segments of the food industry, providing distinct technical advantages that enhance operational efficiency, product quality, and food safety.

Diverse Application Scenarios:

- Large-Scale Slaughterhouses: Precision primary processing, including automated bone saws and carcass splitting machines, ensuring high throughput and consistent cuts. Our chicken cutting machine, for example, can handle thousands of birds per hour, significantly reducing manual labor and increasing hygiene.

- Industrial Meat Packing Plants: For secondary processing, such as dicing, slicing, and grinding. Equipment like our Cutting Rib Machine excels in producing uniform portion sizes, essential for consumer packaging and quality control.

- Commercial Butcheries & Supermarket Meat Departments: Scaled-down yet robust solutions for retail-ready cuts, mincing, and small-batch sausage production. The versatility of our meat cutting machine allows for quick adjustments to meet varied customer demands.

- Catering & Hospitality: High-volume slicing and portioning machines for large kitchens and food service providers, ensuring efficiency and consistent product presentation.

- Processed Meat Production Facilities: Specialized equipment for emulsifying, mixing, stuffing, and smoking in the production of sausages, deli meats, and other value-added products. Our sausage making machine lines are designed for seamless integration into complex production flows.

Core Technical Advantages:

- Precision Engineering: Our equipment features advanced sensor-based cutting systems, ensuring minimal waste and superior yield. For example, our rib cutting technology utilizes optical sensors to detect bone structure, optimizing blade trajectory for maximum meat recovery.

- Hygienic Design & CIP Compatibility: Smooth, crevice-free stainless steel surfaces, IP65/IP67 rated components, and easy-to-disassemble modules facilitate comprehensive Clean-In-Place (CIP) processes, significantly reducing the risk of cross-contamination and bacterial buildup, a cornerstone of FDA and HACCP compliance.

- Automation & Control: PLC-driven systems with intuitive HMI touchscreens enable operators to monitor and adjust parameters in real-time. This level of automation reduces reliance on skilled labor, standardizes output, and enhances overall production efficiency.

- Durability & Longevity: Constructed from heavy-gauge food-grade stainless steel and employing industrial-grade components, our machines are built for continuous operation in demanding environments. Average service life exceeds 10-15 years, with low total cost of ownership (TCO) due to minimal downtime and maintenance.

- Safety Compliance: All equipment is designed and manufactured to meet stringent international safety standards (e.g., CE, UL, CSA), incorporating features like emergency stops, safety interlocks, and protective guarding to ensure operator well-being.

Vendor Comparison and Customized Solutions

Selecting the right meat processing equipment vendor is a critical strategic decision for any B2B operation. While many manufacturers offer standard solutions, distinguishing factors often lie in the depth of technical expertise, commitment to customization, and comprehensive after-sales support.

Key Differentiators in Vendor Selection:

| Feature Category | Our Offering | Typical Standard Vendor |

|---|---|---|

| Technical Expertise | 20+ years in B2B meat processing, dedicated R&D, certified engineers (ISO, HACCP). | General experience, limited R&D investment, basic technical staff. |

| Customization Capability | Full engineering support for bespoke solutions, modular designs for easy adaptation, integration with existing lines. | Limited modifications to standard models, often higher cost for minor changes. |

| Quality & Materials | Exclusive use of food-grade SUS304/316L, premium global components (e.g., Siemens, Schneider), rigorous testing. | May use lower-grade stainless steel or lesser-known components to cut costs. |

| After-Sales Support | 24/7 technical support, global service network, readily available spare parts, remote diagnostics. | Limited hours, regional support only, potential delays in spare part delivery. |

| Compliance & Certifications | CE, USDA, HACCP, FDA-compliant designs, comprehensive documentation. | Basic local certifications, may require client effort for international compliance. |

Customized Solutions for Unique Requirements:

Recognizing that no two processing lines are identical, we specialize in delivering bespoke meat processing equipment solutions. This approach ensures maximum efficiency and seamless integration into existing infrastructure. Customization can involve:

- Tailored Capacity and Throughput: Adjusting machine dimensions, motor power, and automation levels to match specific production volumes, from small artisanal operations to industrial-scale facilities.

- Specialized Cutting & Processing: Developing unique blade configurations or processing modules for unusual meat cuts, specific product shapes (e.g., for specialized sausage making machine lines), or challenging product textures.

- Integration with Existing Systems: Designing equipment with compatible interfaces (e.g., conveyor belts, scales, packaging machines) to optimize the entire production line.

- Enhanced Hygiene Features: Incorporating additional sanitation features, such as advanced spray nozzles or automated cleaning cycles, for facilities with exceptionally strict hygiene protocols.

- Specific Regulatory Compliance: Ensuring that equipment meets unique regional or client-specific regulatory requirements, beyond standard certifications.

Real-World Application Case Studies

Our commitment to providing high-quality meat processing equipment is best demonstrated through the tangible results achieved by our clients. These case studies highlight how our tailored solutions translate into operational excellence and significant ROI.

Case Study 1: Large-Scale Poultry Processor

- Challenge: A major poultry processing plant faced bottlenecks in its chicken deboning line, relying heavily on manual labor which led to inconsistent product quality, high labor costs, and elevated safety risks. The existing chicken cutting machine infrastructure was outdated and inefficient.

- Solution: We implemented a fully automated chicken cutting machine system, including a precision thigh deboner and a wing portioning unit. This solution was specifically designed to integrate seamlessly with their existing overhead conveyor system.

- Results:

- Productivity Increase: 40% increase in processed chicken volume per hour.

- Labor Cost Reduction: 30% reduction in labor allocated to the deboning section.

- Yield Improvement: 2% increase in meat yield due to precise, automated cuts.

- Hygiene & Safety: Enhanced food safety scores and a significant reduction in workplace injuries.

Case Study 2: Boutique Sausage Manufacturer

- Challenge: A growing artisanal sausage producer needed to scale up production to meet increasing demand while maintaining the distinct quality and texture of their specialty sausages. Their manual stuffing process was slow and inconsistent.

- Solution: We provided a semi-automated hydraulic sausage making machine combined with a portioning and twisting unit. This allowed for precise filling and consistent link lengths without compromising the delicate meat emulsion.

- Results:

- Production Increase: 200% increase in daily sausage production.

- Consistency: Near-perfect weight and length consistency for all sausage varieties.

- Product Quality: Preservation of unique texture and flavor profiles due to gentle processing.

Trustworthiness: FAQ, Lead Time, Warranty & Support

Building lasting partnerships is founded on trust and transparency. We are committed to providing clear information regarding our processes, commitments, and support for all meat processing equipment.

Frequently Asked Questions (FAQ)

Q: What is the typical lead time for new meat processing equipment orders?

A: Standard equipment typically ships within 4-6 weeks of order confirmation. Customized solutions may require 8-12 weeks, depending on the complexity of design and fabrication. We provide a detailed timeline upon project scope finalization.

Q: What warranty do you offer on your meat processing equipment?

A: All our equipment comes with a standard 12-month warranty covering parts and labor against manufacturing defects. Extended warranty options are available upon request to provide clients with enhanced peace of mind.

Q: How do you ensure compliance with food safety regulations?

A: Our equipment designs adhere strictly to international food safety standards, including FDA guidelines, HACCP principles, and CE directives. We utilize only food-grade materials (SUS304/316L), employ hygienic design principles (crevice-free, smooth surfaces), and offer complete documentation for compliance auditing.

Q: Can your equipment integrate with existing production lines?

A: Yes, our engineering team specializes in designing modular equipment that can be seamlessly integrated into diverse existing production environments. We offer comprehensive site assessments and custom interface solutions to ensure smooth integration.

Lead Time & Fulfillment Details

From initial consultation to final commissioning, our process is designed for efficiency and transparency. After receiving your detailed requirements, our team provides a precise quotation and production timeline. Manufacturing commences upon deposit, with regular updates provided throughout the production phase. Final quality control and pre-shipment testing are standard, ensuring that your meat processing equipment arrives ready for operation.

Warranty Commitments

Beyond the standard warranty, our commitment extends to offering preventive maintenance programs and readily available spare parts to maximize your equipment's uptime and service life. Our robust manufacturing processes mean less frequent need for repairs, but when issues arise, our warranty ensures prompt and professional resolution.

Customer Support Information

Our dedicated customer support team is available 24/7 to address any technical queries or operational assistance you may require. We offer multiple channels for support, including phone, email, and a secure online portal for service requests and documentation access. On-site installation, training, and troubleshooting services are available globally through our network of certified technicians.

References

- Food and Drug Administration (FDA) – Current Good Manufacturing Practice (CGMP) Regulations for Food and Beverages.

- International Organization for Standardization (ISO) – ISO 9001 Quality Management and ISO 22000 Food Safety Management Systems.

- Hazard Analysis and Critical Control Points (HACCP) principles for Food Safety.

- Global Meat Processing Equipment Market Report (Various leading market research firms, e.g., Grand View Research, MarketsandMarkets).

- European Committee for Standardization (CEN) – EN ISO 12100 Safety of machinery – General principles for design – Risk assessment and risk reduction.

-

Meat Portioning Machine: Precision, Efficiency & Sustainability in Meat ProcessingNewsNov.24,2025

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025