Meat Processing Equipment | Fast, Hygienic, Factory-Direct

Cutting Rib Machine: field notes from a busy bone room

I walked through a chilled cutting room in Shijiazhuang not long ago, and the line chief said something that stuck with me: “speed is nothing without hold-down control.” That’s exactly what good Meat Processing Equipment should nail—repeatable cuts without waste, even when product is a little slick or slightly off-temp.

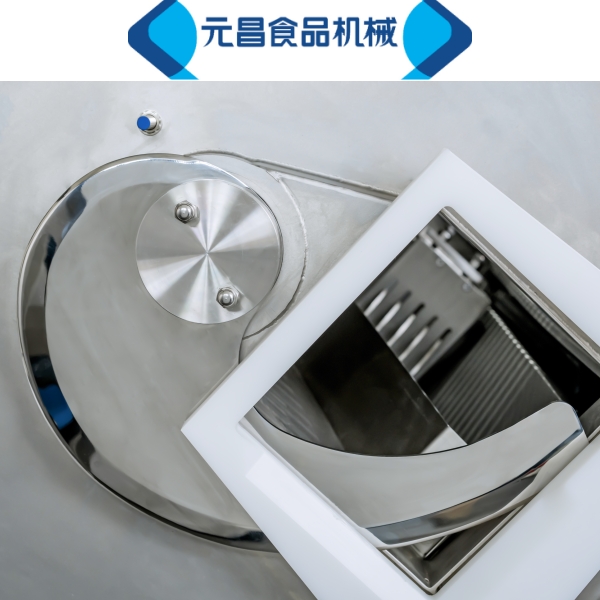

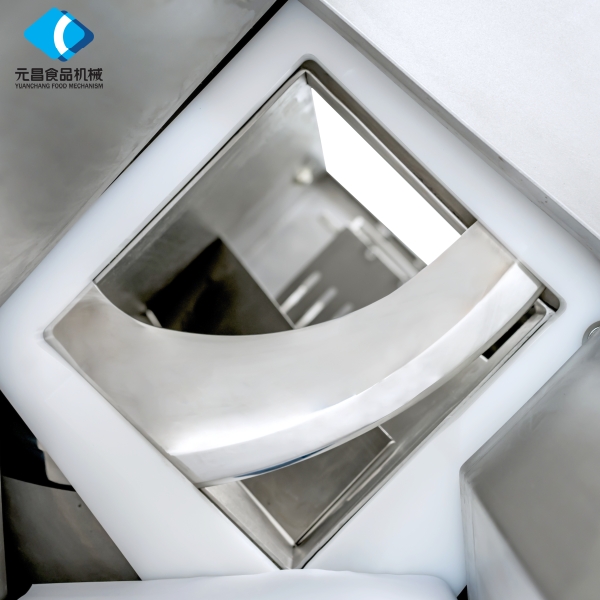

From Shijiazhuang, Hebei Province, China, the Cutting Rib Machine comes with two core ideas: a high-efficiency dynamic feeding system that trims non-productive time, and a smart-cut special claw that prevents product slip. Sounds simple, but—speaking frankly—these two design choices solve 80% of the headaches I hear about on rib lines.

Why it matters now

Labor volatility, yield pressure, and audit intensity are all climbing. Plants want fewer adjustments mid-shift and a tighter standard deviation on cut spacing. Many customers say they’re chasing ±2 mm but will take ±3 mm if the line never stalls. The smart claw here—paired with servo-driven feed—keeps bones aligned when surfaces are wet or cartilage is “springy,” to be honest.

Product specifications (typical values)

| Model | Cutting Rib Machine |

| Throughput | ≈ 600–900 ribs/hour (real-world use may vary with cut pattern/temperature) |

| Cut accuracy | ±2–3 mm typical on chilled product (0–2 °C) |

| Feeding system | High-efficiency dynamic feed with smart-cut claw anti-slip design |

| Materials (contact) | AISI 304/316L stainless, FDA-compliant elastomers |

| Blade | Hardened alloy or optional carbide-tipped blade set |

| Controls | Servo drive, HMI IP65, recipe-based spacing |

| Hygiene & Safety | CE, guarding, emergency stops, sanitary open-frame design |

| Service life | 8–10 years with PM; blades 2–6 weeks per shift pattern |

Process flow and testing

- Materials: chilled pork/beef ribs, 0–2 °C; pre-trimmed and oriented.

- Methods: dynamic feed aligns ribs; smart claw stabilizes; servo indexes; blade executes recipe spacing.

- QA/testing: verification of cut spacing (ISO 2859 sampling), swab tests per HACCP plan, noise ≤ 78–82 dBA around the operator, lockout/tagout checks each start-up.

- Standards: ISO 14159 hygienic design, EN 1672-2, CE Machinery Directive; supports HACCP documentation and traceability.

- Industries: pork primals, beef short ribs, export spec trimming, ready-to-cook packs.

Vendor comparison (quick take)

| Vendor/Model | Lead Time | Accuracy | Support | Certs |

|---|---|---|---|---|

| YC Meat Mech Cutting Rib Machine | ≈ 6–10 weeks | ±2–3 mm | Remote + on-site in APAC | CE, food-grade materials |

| Global Brand A Rib Cutter | ≈ 10–16 weeks | ±2 mm | Global field teams | CE, UL |

| Regional Integrator Custom Line | ≈ 8–12 weeks | ±3–4 mm | Local technician | CE (varies by build) |

It seems that the YC unit competes on stability and lead time; if you need enterprise service footprints, some multinationals still have an edge. Different plants, different priorities.

Customization and integrations

- Recipe packs: rib spacing presets, left/right feed orientation.

- Blade kits: hardness options for heavy beef vs. pork.

- Connectivity: OPC UA or Modbus to SCADA; batch ID to printers.

- Safety: extra light curtains, interlocked doors, stainless guards.

Mini case study (real-world numbers)

A mid-sized pork processor in North China swapped an older cutter for this unit. After a two-day SAT, average spacing deviation dropped from 3.8 mm to 2.4 mm; trim loss fell ≈ 0.6%. Unplanned stops went from 7/day to 2–3/day in the first month. The QA manager told me, “the claw doesn’t let go—even when the rack is a touch warm after lunch.” Not scientific, but the yield report agreed.

Noise readouts were 79 dBA at operator ear height; blade condition checks every 4 hours met the plant’s HACCP verification. That’s the kind of steady, boring reliability you want from Meat Processing Equipment.

Certifications, hygiene, and upkeep

Built around open-frame stainless with sloped surfaces, the unit supports foam-and-rinse washdowns and visual inspection (EHEDG-style thinking). CE-compliant guarding and E-stops are standard. For plants under USDA or export audits, it aligns with HACCP/PRP expectations. In my notes, PM every 500 hours (or monthly) kept bearings happy and operators happier. If you’re standardizing Meat Processing Equipment across sites, that PM interval is easy to roll into your CMMS.

Bottom line? If your bottleneck is slip-induced miscuts or slow indexing, this design is worth a look. And yes, the origin story matters: Shijiazhuang’s cluster of metalwork talent shows up in the fit and finish.

Authoritative citations

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025

-

Best Commercial Marinating Machines for Meat Processing | Efficient & ScalableNewsNov.20,2025