Meat Filling Machine – Fast, Hygienic, Precise Sausage Maker

Lunch Meat Filling Machine for Ground Meat: field notes from the production floor

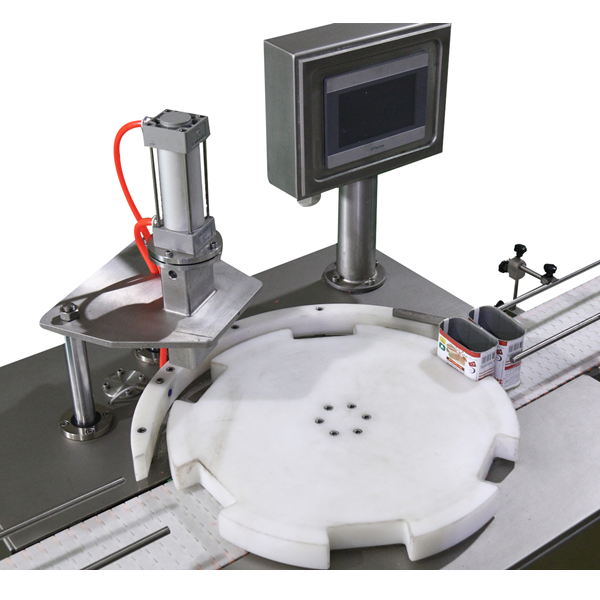

If you’re shopping for a Meat Filling Machine, here’s the quick take: vacuum filling has quietly become the backbone of modern sausage and luncheon meat lines. I’ve seen it in small co-packers and sprawling plants alike. This particular model originates from Shijiazhuang, Hebei Province, China, and pairs the ZKG vacuum stuffer with the Mech.Greatwall Double Clipper JCSK-A. On paper it’s a classic combo; in practice, it’s a workhorse—assuming you spec it right.

Why vacuum filling matters (and what’s trending)

The market’s nudging toward higher yield, cleaner labels, and less air in the pack. Vacuum systems reduce entrained oxygen—better sliceability, fewer voids, tighter texture. In 2025, buyers are asking for data logging, clipper integration, and faster changeovers. To be honest, uptime is the real KPI. Many customers say they’ll accept “good enough” specs if service is fast and spare parts are predictable.

Core specs at a glance

| Parameter | Typical Value (≈, real-world use may vary) |

|---|---|

| Throughput | ≈ 2,500–3,500 kg/h with ground meat emulsions |

| Fill accuracy | ±1–2 g per portion (with rotary vane pump) |

| Vacuum level | Up to −0.095 MPa; pump ≈ 40–63 m³/h |

| Hopper capacity | ≈ 180–250 L with safety grate |

| Materials / finish | AISI 304 (option 316L), Ra ≤ 0.8 μm product zone |

| IP rating | IP65 electrical enclosures |

| Clipper compatibility | Mech.Greatwall JCSK-A, plus optional adapters |

Process flow and validation

Materials: ground pork/beef, brine, phosphates (or not), spices, plus cellulose/collagen casings. Method: pre-emulsify to target particle size, feed to the Meat Filling Machine, evacuate air, portion, and clip. Typical QA: texture profile analysis, brine pickup checks, void counts per 100 slices, and metal detection downstream. FAT/SAT protocols often include 8-hour continuous run to verify thermal stability, vacuum hold, and ±2 g weight constancy. Service life? With routine seals and vane replacements, I’ve seen 8–12 years.

Industries: delis, QSR suppliers, pet food (emulsions), plant-based analogs, and export-focused sausage plants. Certifications commonly requested: CE, ISO 22000/HACCP alignment, and EHEDG-informed hygienic design. Some buyers in North America additionally ask for UL panels and FSIS compliance in facility SOPs.

How it stacks up (vendor comparison)

| Vendor / Model | Strengths | Considerations |

|---|---|---|

| YC ZKG + JCSK-A | Value pricing, solid vacuum, easy clipper pairing | Service network still growing outside Asia |

| Handtmann VF800 series | High accuracy, strong global support | Premium cost; software options add up |

| Vemag HP E | Robust build, versatile attachments | Footprint slightly larger in some configs |

| Rex RVF 436 | Compact, efficient for mid-scale plants | Throughput ceiling lower than flagship units |

Customization and real-world feedback

- Options: 316L contact parts, servo portioning, anti-bridging agitators, quick-change horns, data logging (CSV/OPC-UA).

- Sanitation: CIP-friendly manifolds, tool-less disassembly points, gasket kits rated for caustics up to 2% at ≈ 55°C.

- Test data (pilot runs): O2 in emulsion reduced by ≈ 35–50% vs. non-vacuum fill; slice voids down to

Customer notes I keep hearing: “It just runs” from a Shandong plant doing 22 t/day of luncheon meat; a Polish deli reported a 1.3% yield bump after switching to vacuum portioning; a US co-packer liked the straightforward clipper sync. Minor gripe: UI translations could be cleaner—nothing show-stopping.

Buying checklist

- Match pump size to viscosity and dice size. Brine-heavy mixes need more vacuum headroom.

- Verify FAT: target ±2 g at your exact recipe; bring your casings.

- Ask for spare parts kit (12–18 months), vane/rotor maintenance plan, and operator training.

- Confirm certifications (CE), HACCP documentation pack, and electrical standards for your region.

Bottom line: the Meat Filling Machine in this pairing is a pragmatic, budget-sensible way to get vacuum-quality fills and tight clips. Not flashy. But it earns its keep.

Authoritative citations

- ISO 22000:2018 – Food safety management systems.

- EHEDG Guidelines – Hygienic Equipment Design Criteria.

- USDA FSIS – Meat and Poultry Processing Regulations (applicable facility compliance).

- EU Machinery Directive 2006/42/EC – CE conformity for machinery.

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025

-

Best Commercial Marinating Machines for Meat Processing | Efficient & ScalableNewsNov.20,2025